Steel scrap rating and database building system and method

A technology for steel scrap and steel trough, applied in the direction of measuring devices, instruments, mechanical excitation analysis, etc., to achieve the effect of increasing yield, reducing smelting cost and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] specific implementation plan

[0033] The present invention will be further described below in conjunction with accompanying drawing and example.

[0034] This embodiment is an example of a steelmaking plant utilizing the waste steel rating and database building system of the present invention to smelt scrap steel in an electric arc furnace.

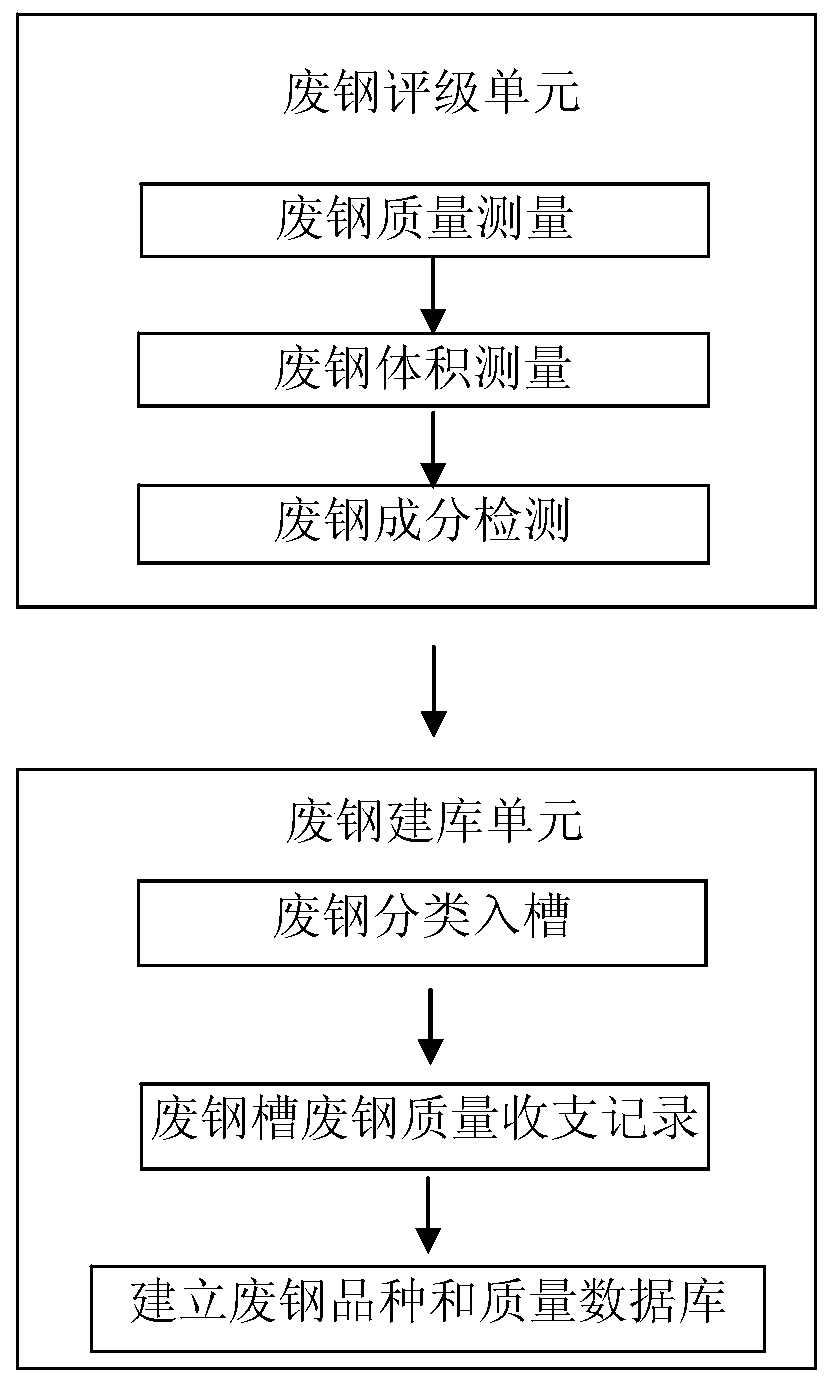

[0035] Such as figure 1 As shown, the scrap steel rating and warehouse building system includes a scrap steel rating unit and a scrap steel warehouse building unit. The scrap steel rating unit includes processes such as scrap steel quality measurement, scrap steel volume measurement, and scrap steel composition detection; Processes such as branch records and establishment of stockyard scrap database.

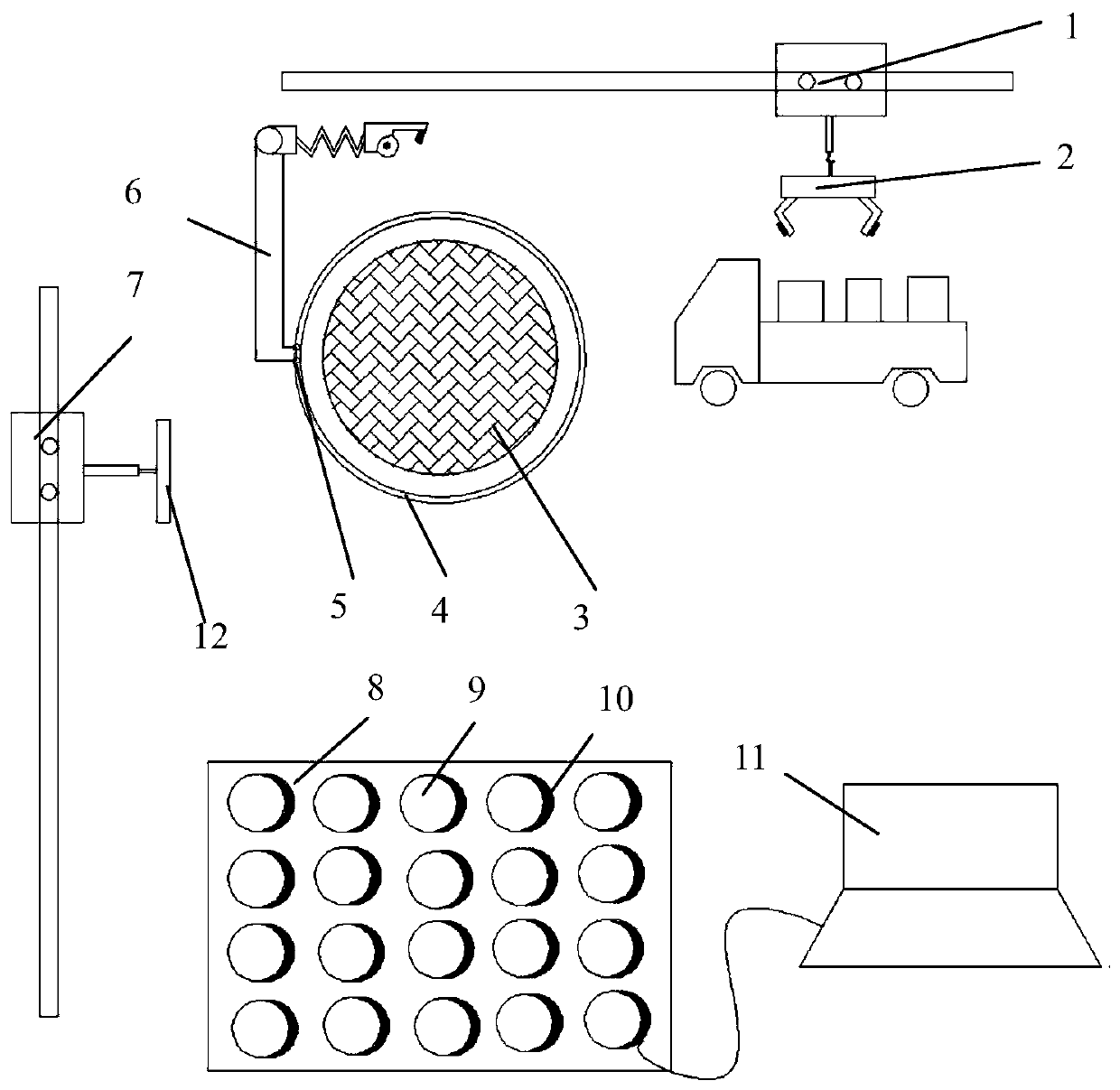

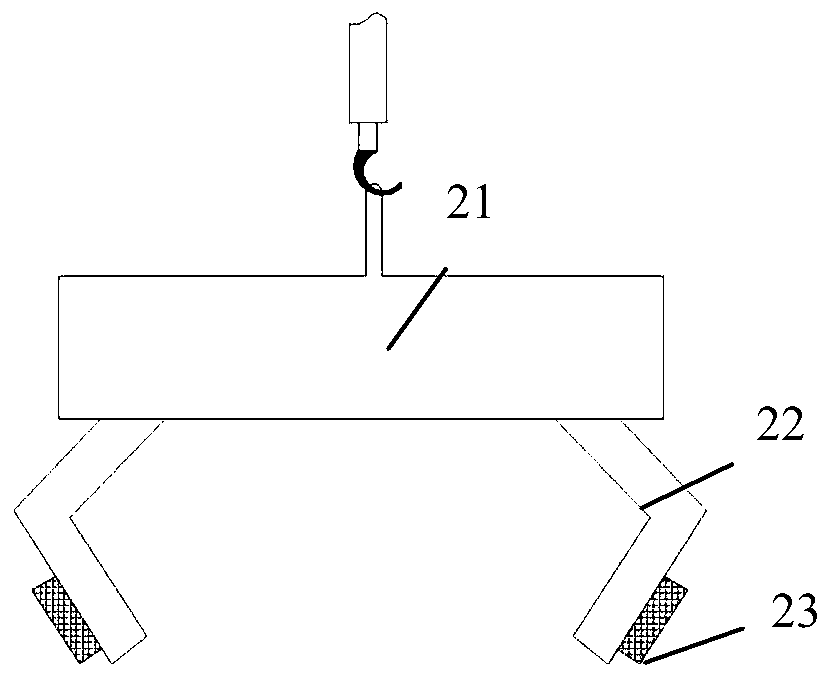

[0036] combine figure 2 , the steel scrap rating unit is composed of a single-girder crane A1, a spreader 2, a steel unloading pit 3, a slide rail 4, a pulley 5 and a mechanical arm 6; the hook of the single-girder crane A is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com