Touch and slip sensor and preparation method thereof

A sensor and touch-slip technology, applied in the field of sensors, can solve the problems of not being able to judge the direction of sliding, measuring the speed of sliding or the shear force of objects acting on the device, the sensors are not unified, and large areas, etc., to achieve convenient production , The preparation method is simple and the production process is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

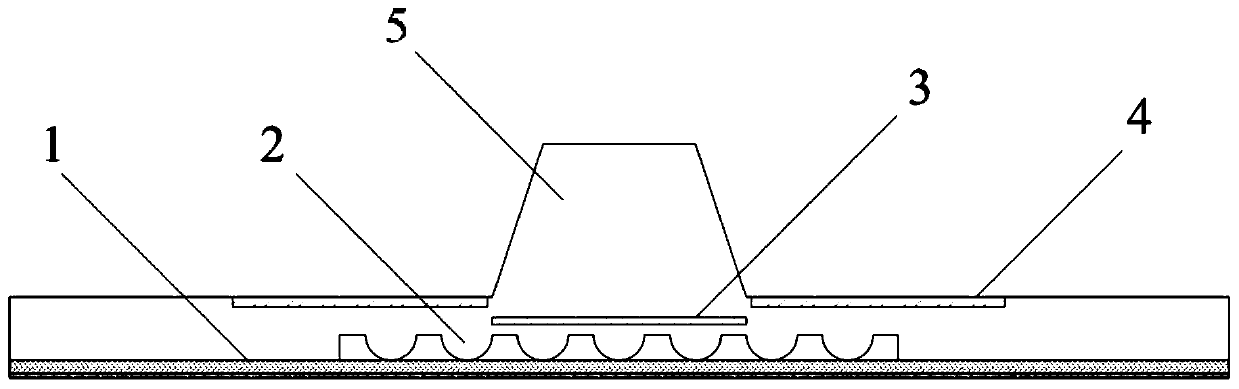

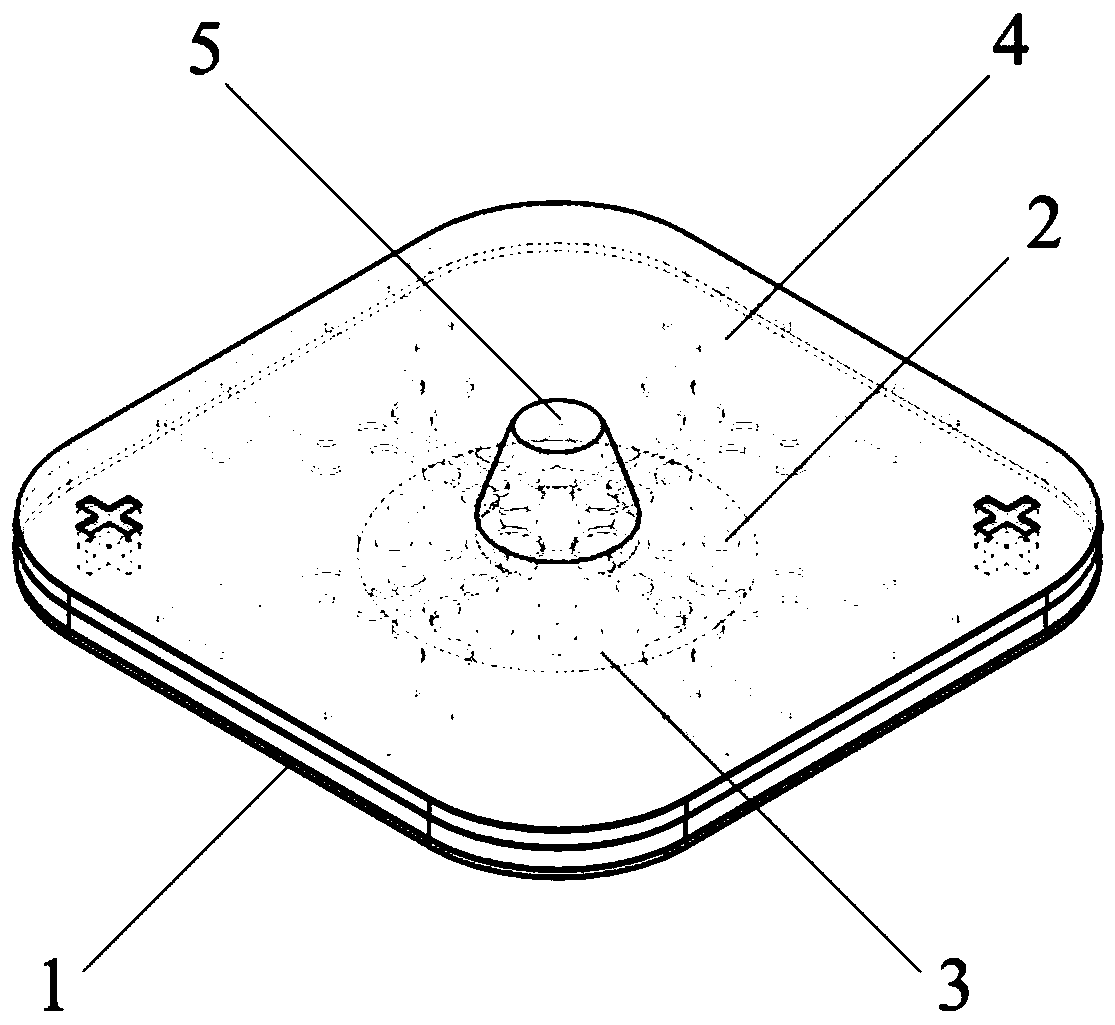

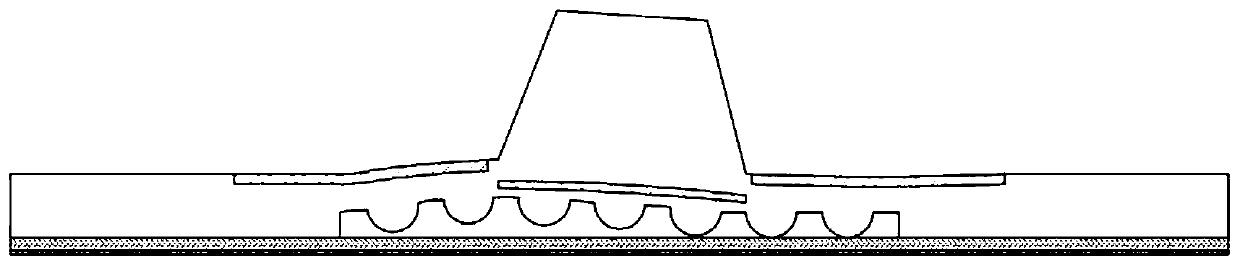

[0037] refer to figure 1 and figure 2 , in one embodiment, a kind of tactile sensory sensor, comprises the structure of 5 layers closely assembled together, according to the sequence from bottom to top, the first layer is the organic polymer thin film 1 that the bottom surface is covered with conductive material, the second The layer is an organic material 2 with a groove in the center, the opening of the groove faces the first layer, and the inside of the groove is uniformly distributed with an array of protrusions whose height is equal to the depth of the groove, and the second layer has The outer area is closely connected with the first layer, the protrusion array inside the groove is in contact with the surface of the first layer, and separates w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com