Intelligent manufacturing robot power consumption control device for automatic warehousing and logistics

A power consumption control, warehousing and logistics technology, applied in control/regulating systems, instruments, adjusting electrical variables, etc., can solve the problems of inaccurate switching action, worry about the reliability of mechanical power switches, errors, etc., and improve the reliability of switching. performance, guarantee the normal working state and stability, improve the stability and reliability and guarantee the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Such as figure 1 As shown, the present invention provides an intelligent manufacturing robot power consumption control device for automatic warehousing and logistics, including a power supply module and a power consumption control module for monitoring the output power quality of the power supply module.

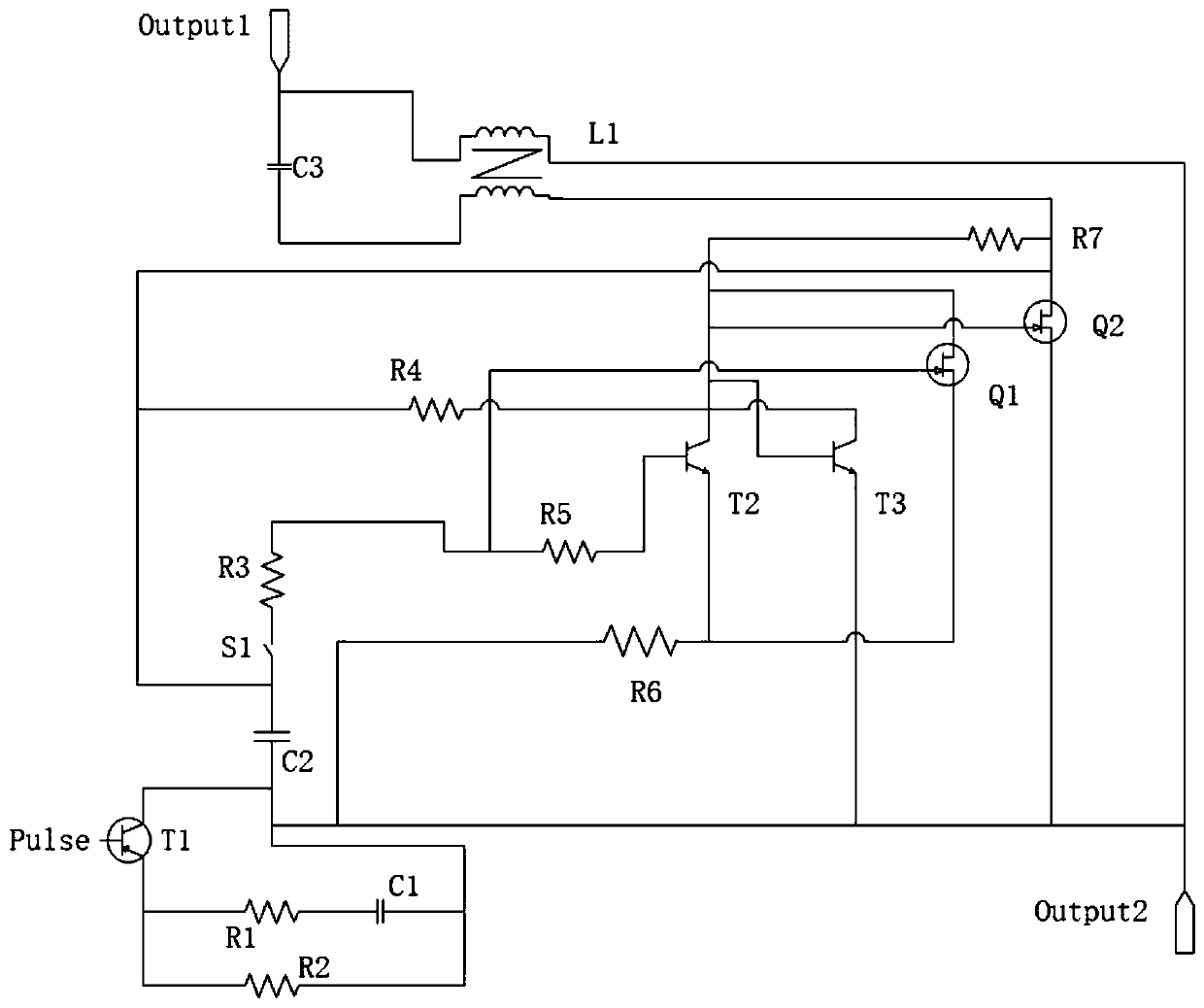

[0017] Preferably, the power consumption control module includes: a micro-power consumption switch circuit for controlling the power supply module, and a monitoring unit for monitoring an output signal output between two output terminals of the switch circuit.

[0018] Preferably, as figure 2 As shown, the micro-power switch circuit includes: transistors T1, T2 and T3, capacitors C1, C2 and C3, resistors R1, R2, R3, R4, R5, R6, R7, field effect transistors Q1, Q2, switches S1, bidirectional rectifier L1, output terminals Output1 and Output2; the base of the transistor T1 is connected to the pulse signal Pulse, the emitter is respectively connected to the first end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com