Preparation method of ultrafine ashless coal for new energy anode

An ash-free coal and new energy technology, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of narrow distribution range, high ash content, and large particle size of coal powder, so as to improve the impurity removal effect and meet the Purity and particle size requirements, and the effect of promoting the impurity removal process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The anthracite was preliminarily crushed to -200 mesh, placed in a corundum crucible, and kept at 600°C for 8 hours in a nitrogen atmosphere in a muffle furnace to remove volatile matter.

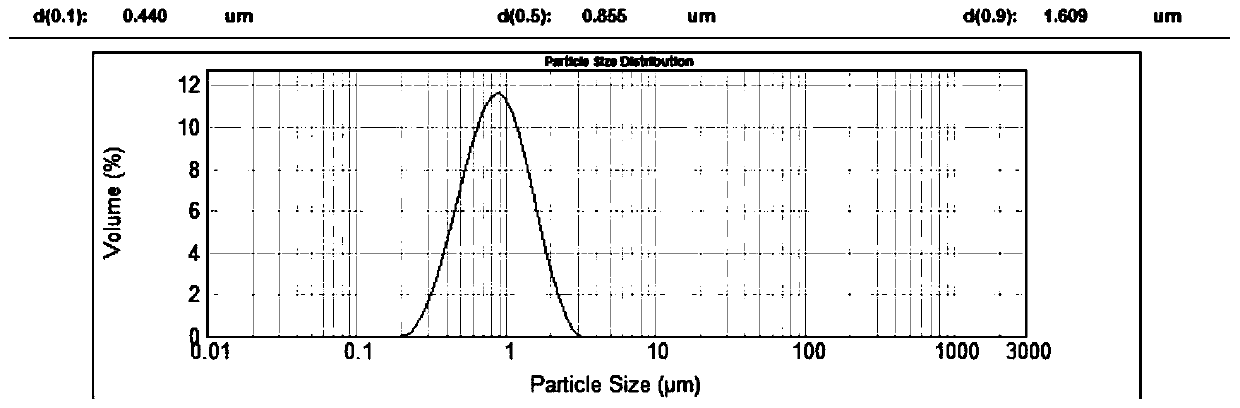

[0041] Take 30g of pulverized coal after devolatilization, add it into the zirconia ball mill tank, add 10ml of absolute ethanol into the ball mill tank, choose zirconia balls as the medium ball, and control the gradation of medium balls as medium balls: small balls = 1:1, Ball-to-material ratio = 10:1, planetary ball mill speed 300r / min, ball milling time 12h, after drying in a vacuum drying oven for 4h, a well-dispersed ultra-fine coal powder was obtained, and the particle size of the coal powder was measured by a laser particle size tester distribution, such as figure 1 As shown, D50=0.855 μm, D90=1.609 μm.

[0042] Mix ultra-fine coal powder and NaOH at a mass ratio of 0.6:1.0, add 130g of deionized water, 10wt% ethanol (NaOH concentration is 4.0mol / L), soak in water and alkali ...

Embodiment 2

[0044] Anthracite was initially crushed to -200 mesh, placed in a corundum crucible, and kept at 650°C for 4 hours in a nitrogen atmosphere in a muffle furnace to remove volatile matter.

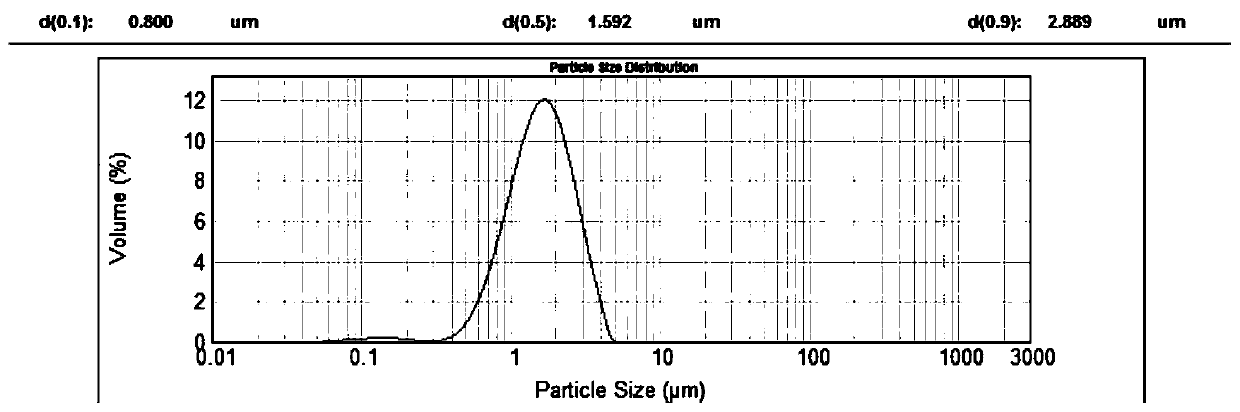

[0045] Take 30g of pulverized coal after devolatilization, add it into the zirconia ball mill tank, add 10ml of absolute ethanol into the ball mill tank, choose zirconia balls as the medium ball, and control the gradation of medium balls as medium balls: small balls = 1:1, Ball-to-material ratio = 5:1, planetary ball mill speed 300r / min, ball milling time 10h, after drying in a vacuum drying oven for 4h, a well-dispersed ultra-fine coal powder is obtained, and the particle size of the coal powder is measured by a laser particle size tester distribution, such as figure 2 As shown, D50=1.592 μm, D90=2.889 μm.

[0046] Mix ultra-fine coal powder and NaOH at a mass ratio of 0.8:1.0, add 130g of deionized water and 10wt% ethanol (NaOH concentration is 5.0mol / L), soak in water and alkali at 210°...

Embodiment 3

[0048] Anthracite was initially crushed to -200 mesh, placed in a corundum crucible, and kept at 650°C for 4 hours in a nitrogen atmosphere in a muffle furnace to remove volatile matter.

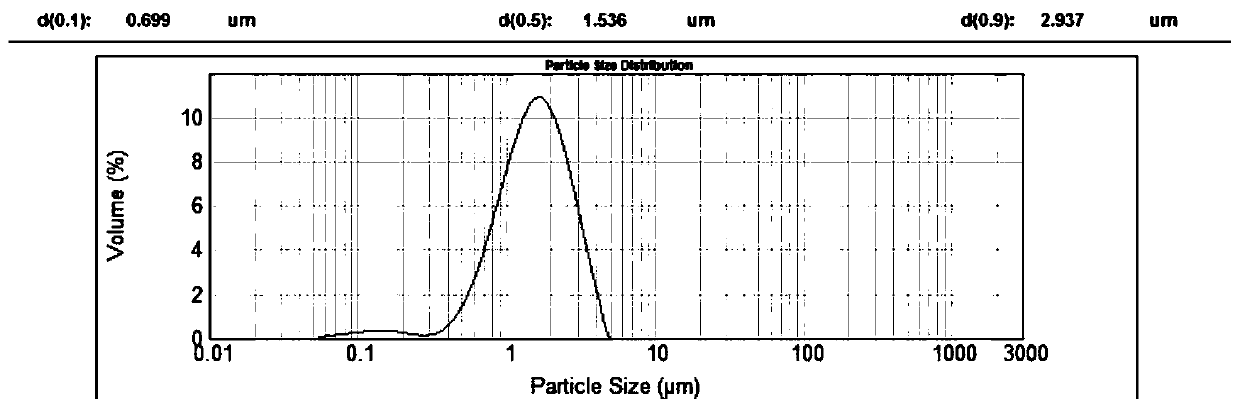

[0049] Take 30g of pulverized coal after devolatilization, add it into the zirconia ball mill tank, add 10ml of absolute ethanol into the ball mill tank, choose zirconia balls as the medium ball, and control the gradation of medium balls as medium balls: small balls = 1:2, Ball-to-material ratio = 10:1, planetary ball mill speed 300r / min, ball milling time 8h, after drying in a vacuum drying oven for 4h, a well-dispersed ultra-fine coal powder is obtained, and the particle size of the coal powder is measured by a laser particle size tester distribution, such as image 3 As shown, D50=1.536 μm, D90=2.937 μm.

[0050] Mix ultra-fine coal powder and NaOH at a mass ratio of 0.6:1.0, add 130g of deionized water, 10wt% ethanol (NaOH concentration is 4.0mol / L), soak in water and alkali at 210°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com