Preparing method of superfine pulverized coal

A technology of fine coal powder and raw coal, applied in the field of ultra-fine coal powder preparation, can solve the problems of wide particle size distribution of coal powder, complex preparation process, narrow distribution interval, etc., achieve narrow distribution interval, optimize process flow, and prevent agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

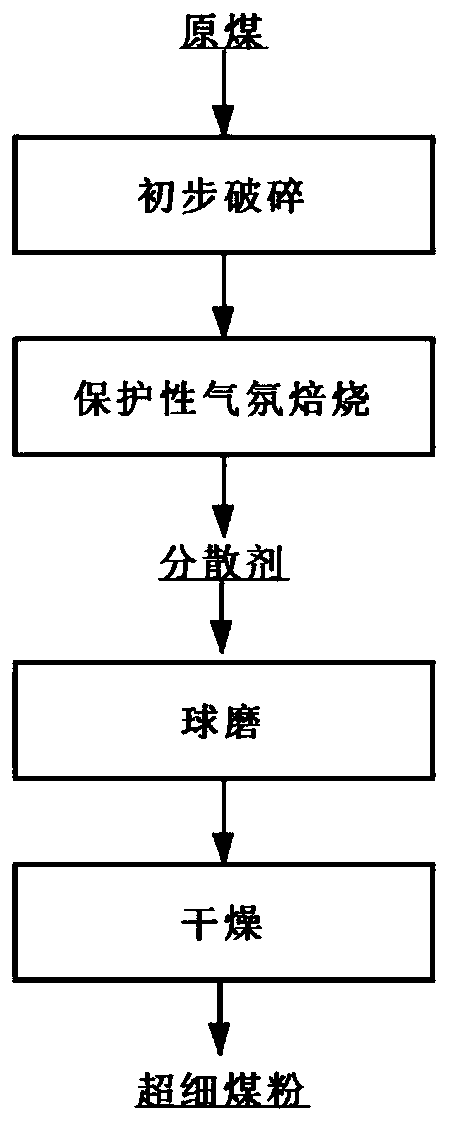

Method used

Image

Examples

Embodiment 1

[0030] Anthracite coal from a place is initially crushed to -200 mesh, placed in a corundum crucible, and kept at 600°C for 8 hours in a nitrogen atmosphere in a muffle furnace to remove volatiles.

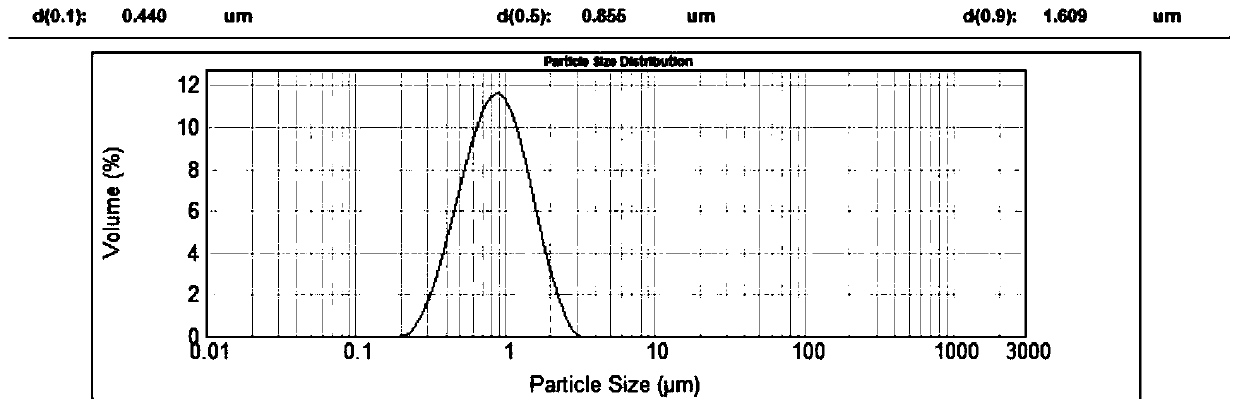

[0031] Take 50g of the devolatilized coal powder and add it to the zirconia ball mill tank, add 10ml of absolute ethanol to the ball mill tank, select zirconia ball as the medium ball, and control the gradation of the medium ball to the medium ball: small ball = 1:1, Ball-to-material ratio = 10:1, planetary ball mill speed 300r / min, ball milling time 12h, and 4h drying in a vacuum drying oven to obtain ultrafine coal powder with good dispersibility. The particle size of the coal powder is measured by a laser particle size tester. Distribution, such as figure 2 As shown, D50=0.855 μm and D90=1.609 μm. The fixed carbon content is 96.5%.

Embodiment 2

[0033] Anthracite coal from a place is initially crushed to -200 mesh, placed in a corundum crucible, and kept at 650°C for 4h in a nitrogen atmosphere in a muffle furnace to remove volatiles.

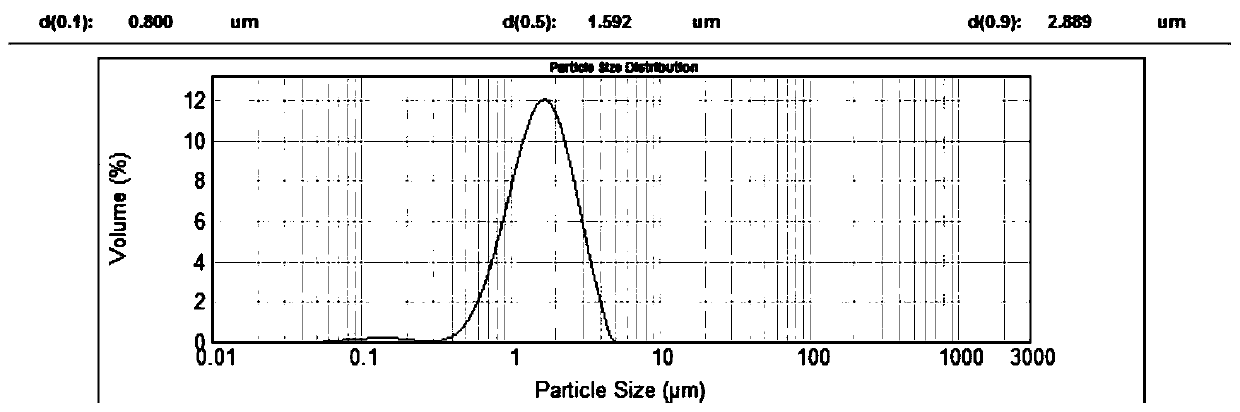

[0034] Take 50g of the devolatilized coal powder and add it to the zirconia ball mill tank, add 10ml of absolute ethanol to the ball mill tank, select zirconia ball as the medium ball, and control the gradation of the medium ball to the medium ball: small ball = 1:1, Ball-to-material ratio=5:1, planetary ball mill speed 300r / min, ball milling time 10h, and 4h drying in a vacuum drying oven to obtain ultrafine coal powder with good dispersibility. The particle size of the coal powder is measured by a laser particle size tester. Distribution, such as image 3 As shown, D50=1.592 μm and D90=2.889 μm. The fixed carbon content is 96.3%.

Embodiment 3

[0036] Anthracite coal from a place is initially crushed to -200 mesh, placed in a corundum crucible, and kept at 650°C for 4h in a nitrogen atmosphere in a muffle furnace to remove volatiles.

[0037] Take 50g of the devolatilized coal powder and add it to the zirconia ball milling tank. Add 10ml of absolute ethanol to the ball milling tank. The medium ball is zirconia ball, and the gradation of the control medium ball is medium ball: small ball = 1:2, Ball-to-material ratio=10:1, planetary ball mill speed 300r / min, ball milling time 8h, and 4h drying in a vacuum drying oven to obtain ultrafine coal powder with good dispersibility. The particle size of coal powder is measured by laser particle size tester. Distribution, such as Figure 4 As shown, D50=1.536 μm and D90=2.937 μm. The fixed carbon content is 96.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com