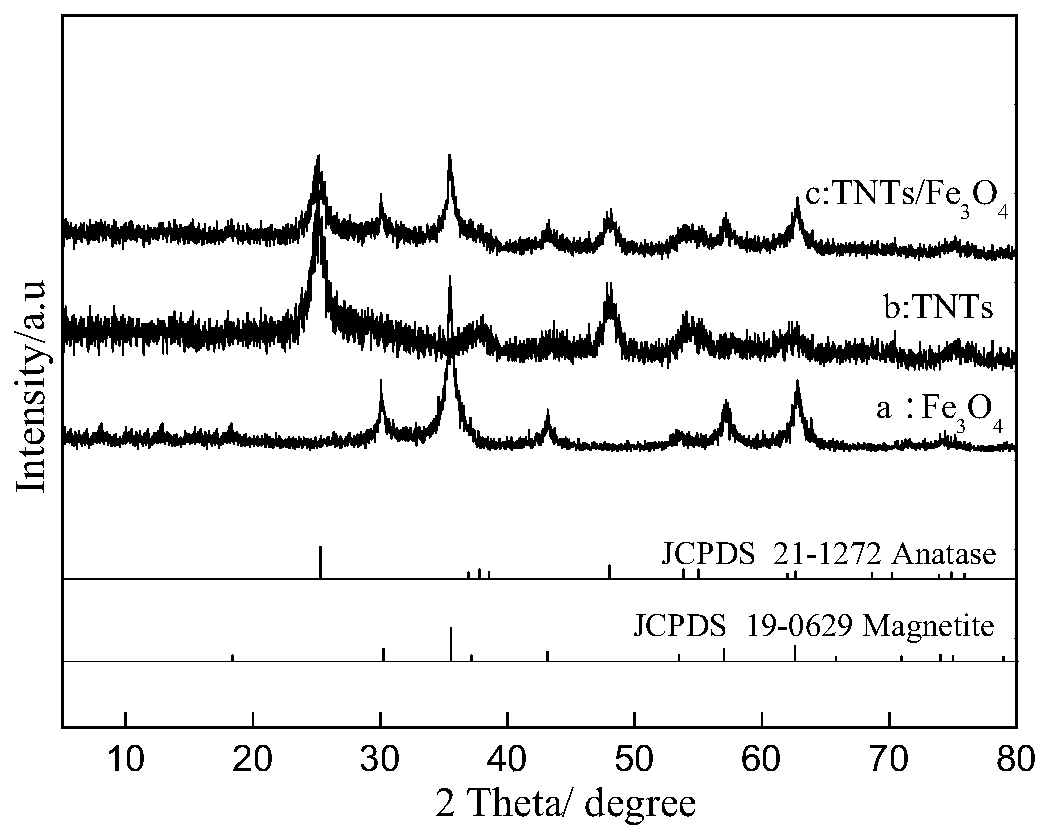

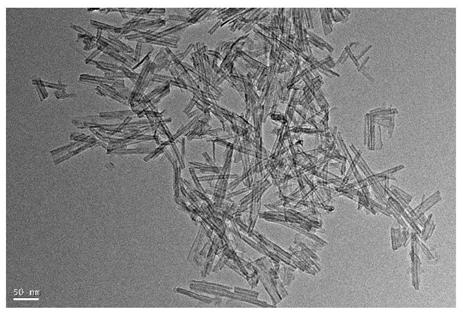

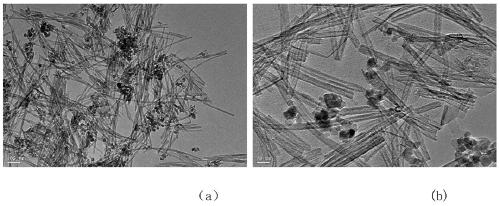

Defect type TNTs composite material capable of achieving magnetic separation and preparation method thereof

A composite material, defect-type technology, applied in the field of photocatalytic materials, can solve the problems of low photocatalytic activity, difficult solid-liquid separation, limitations, etc., to achieve the effect of improving separation ability, expanding visible light response range, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of a magnetically separable defect-type TNTs composite material, comprising the following steps:

[0024] 1) Weigh a certain amount of P 25 Disperse in deionized water, sonicate for 0.5h, stir for 0.5h to ensure complete mixing, and then add a certain amount of FeCl with a molar ratio of 1.5:1 3 ·6H 2 O and FeSO 4 ·7H 2 O, then continue to sonicate for 15 minutes and stir for 15 minutes to ensure complete mixing;

[0025] 2) Add 1M NaOH solution dropwise to the above mixture to make the pH of the solution equal to 10, then add a certain amount of NaOH to transfer the mixture to a hydrothermal reactor, and then heat the reactor at 120°C for 24 hours ;

[0026] 3) After cooling, wash with deionized water until neutral, and soak in 0.01M HCl solution for 1 hour;

[0027] 4) Wash several times with deionized water, then wash several times with absolute ethanol for magnetic separation, dry in vacuum at 60°C, N 2 Calcining at 250° C. for 50 min und...

Embodiment 2

[0029] A preparation method of a magnetically separable defect-type TNTs composite material, comprising the following steps:

[0030] 1) Weigh a certain amount of P 25 Disperse in deionized water, sonicate for 0.5h, stir for 0.5h to ensure complete mixing, and then add a certain amount of FeCl with a molar ratio of 2:1 3 ·6H 2 O and FeSO 4 ·7H 2 O, then continue to sonicate for 15 minutes and stir for 15 minutes to ensure complete mixing;

[0031] 2) Add 1M NaOH solution dropwise to the above mixture to make the pH of the solution equal to 10, then add a certain amount of NaOH to transfer the mixture to a hydrothermal reactor, and then heat the reactor at 120°C for 24 hours ;

[0032] 3) After cooling, wash with deionized water until neutral, and soak in 0.01M HCl solution for 1 hour;

[0033] 4) Wash several times with deionized water, then wash several times with absolute ethanol for magnetic separation, dry in vacuum at 60°C, N 2 Calcining at 300° C. for 60 min under...

Embodiment 3

[0035] A preparation method of a magnetically separable defect-type TNTs composite material, comprising the following steps:

[0036] 1) Weigh a certain amount of P 25 Disperse in deionized water, sonicate for 0.5h, stir for 0.5h to ensure complete mixing, then add a certain amount of FeCl with a molar ratio of 2.5:1 3 ·6H 2 O and FeSO 4 ·7H 2 O, then continue to sonicate for 15 minutes and stir for 15 minutes to ensure complete mixing;

[0037] 2) Add 1M NaOH solution dropwise to the above mixture to make the pH of the solution equal to 10, then add a certain amount of NaOH to transfer the mixture to a hydrothermal reactor, and then heat the reactor at 120°C for 24 hours ;

[0038] 3) After cooling, wash with deionized water until neutral, and soak in 0.01M HCl solution for 1 hour;

[0039] 4) Wash several times with deionized water, then wash several times with absolute ethanol for magnetic separation, dry in vacuum at 60°C, N 2 Calcining at 350° C. for 70 minutes und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube outer diameter | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com