Sawing wire, steel for sawing wire, and production method thereof

A technology for cutting steel wires and production methods, which is applied in the field of steel for cutting steel wires and cutting steel wires, and can solve the problems of large number density of inclusions, low tensile strength, and large size of inclusions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

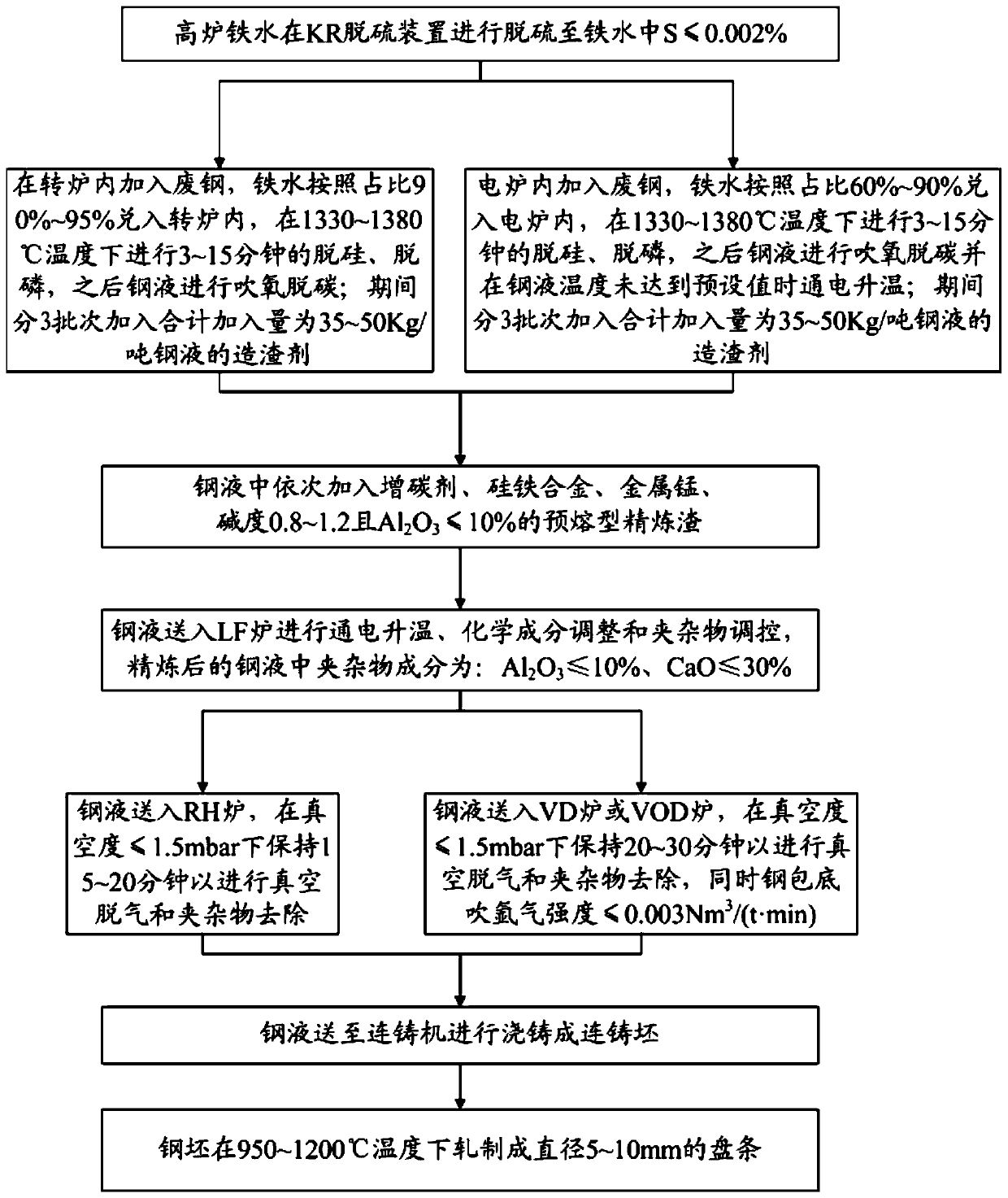

Method used

Image

Examples

Embodiment 1

[0068] In this embodiment, five test examples with serial numbers A, B, C, D, and E are illustrated, and the specific details of this embodiment will be introduced below.

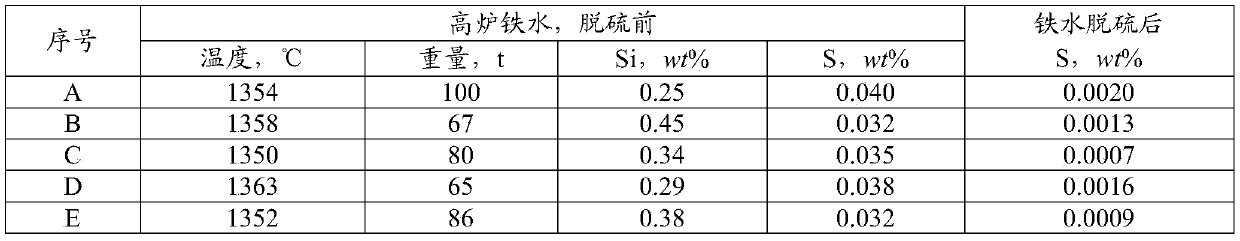

[0069] (1) Pretreatment

[0070] Take blast furnace molten iron for desulfurization in KR desulfurization device. The temperature, weight, Si content, S content of blast furnace molten iron and the S content in molten iron after desulfurization are shown in Table 1.

[0071] [Table 1]

[0072]

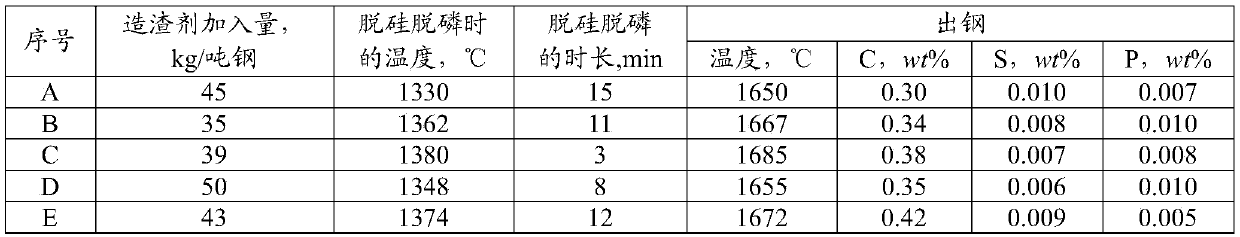

[0073] (2) Electric furnace blowing

[0074] Add steel scrap and pretreated molten iron into a 100t electric furnace, and mix the two into molten steel with a total weight of 110±2t; add the first batch of slagging agent to the molten steel and then perform desiliconization and dephosphorization; The second batch of slagging agent is added to the molten steel after silicon and dephosphorization; after that, the molten steel is subjected to oxygen blowing decarburization, and during the process of oxygen blowing...

Embodiment 2

[0100] In this embodiment, five test examples with serial numbers H, I, J, K, and L are illustrated, and the specific details of this embodiment will be introduced below.

[0101] (1) Pretreatment

[0102] Take blast furnace molten iron for desulfurization in KR desulfurization device. The temperature, weight, Si content, S content of blast furnace molten iron and the S content in molten iron after desulfurization are shown in Table 8.

[0103] [Table 8]

[0104]

[0105] (2) Converter blowing

[0106] Add steel scrap and pretreated molten iron into a 120t converter, and mix the two into molten steel with a total weight of 130±2t; add the first batch of slagging agent to the molten steel and then perform desiliconization and dephosphorization; The second batch of slagging agent is added to the molten steel after silicon and dephosphorization; after that, the molten steel is subjected to oxygen blowing decarburization, and during the oxygen blowing decarburization process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com