A Mining Stress Assessment Method Based on Microseismic Damage Reconstruction

A technology of dynamic stress and microseismic, applied in seismology, force measurement, seismic signal processing, etc., can solve problems such as lack of physical-mechanical correlation, difficulty in real-time inversion, and calculation result errors, etc., to achieve obvious physical-mechanical significance, suitable Programmable, time-sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example Analysis Select the microseismic monitoring data of a coal mine working face during the mining stage for analysis. Since the mining speed of this working face is approximately uniform and stable, and the average daily footage is 1.2m, the calculation of the present invention is finally explained using the strain-time model as an example. Implement the present invention according to the idea of the present invention:

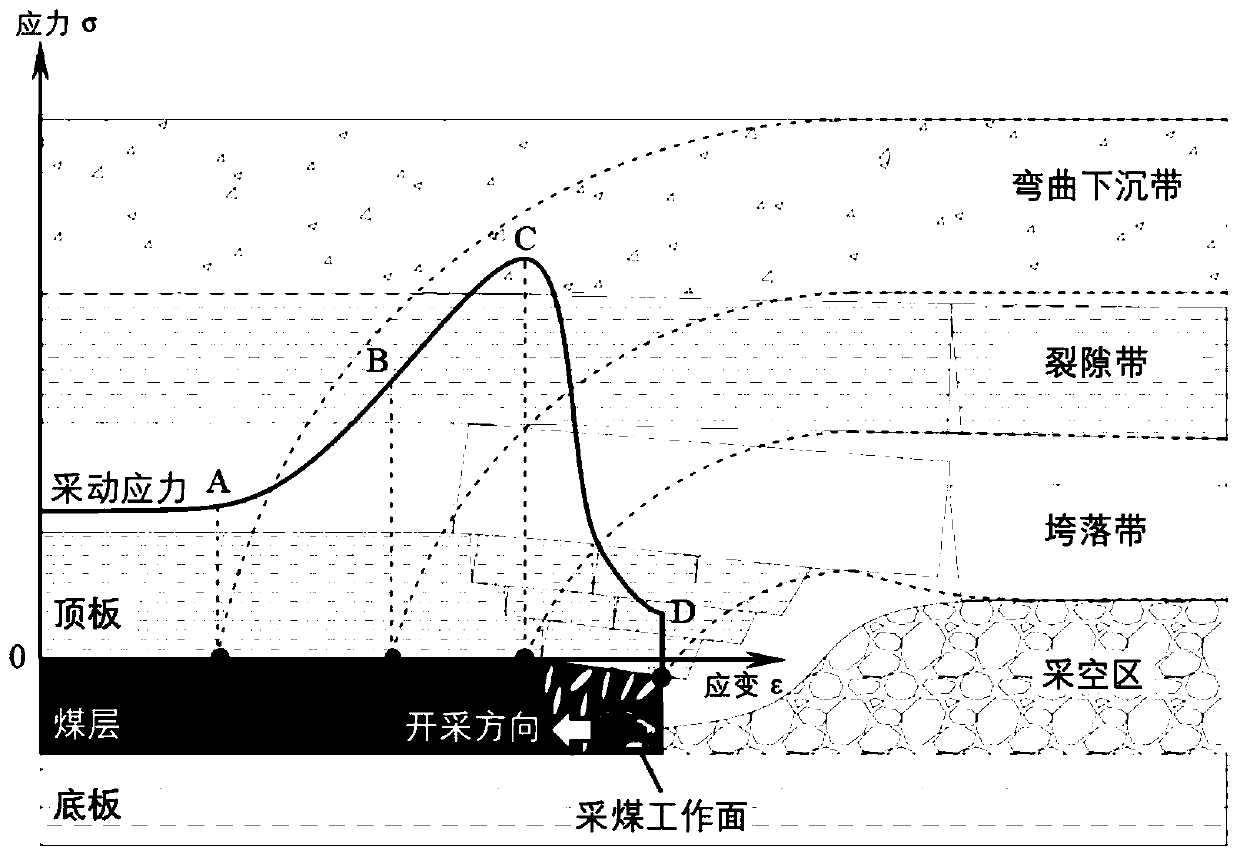

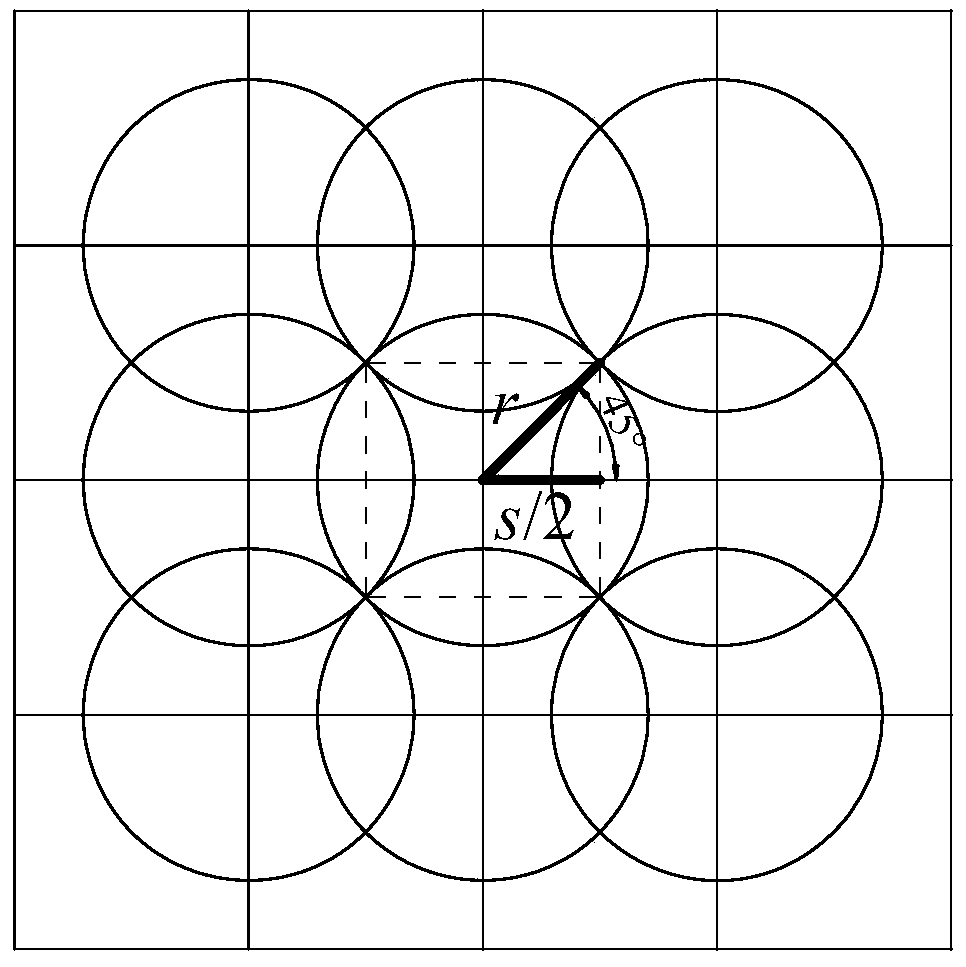

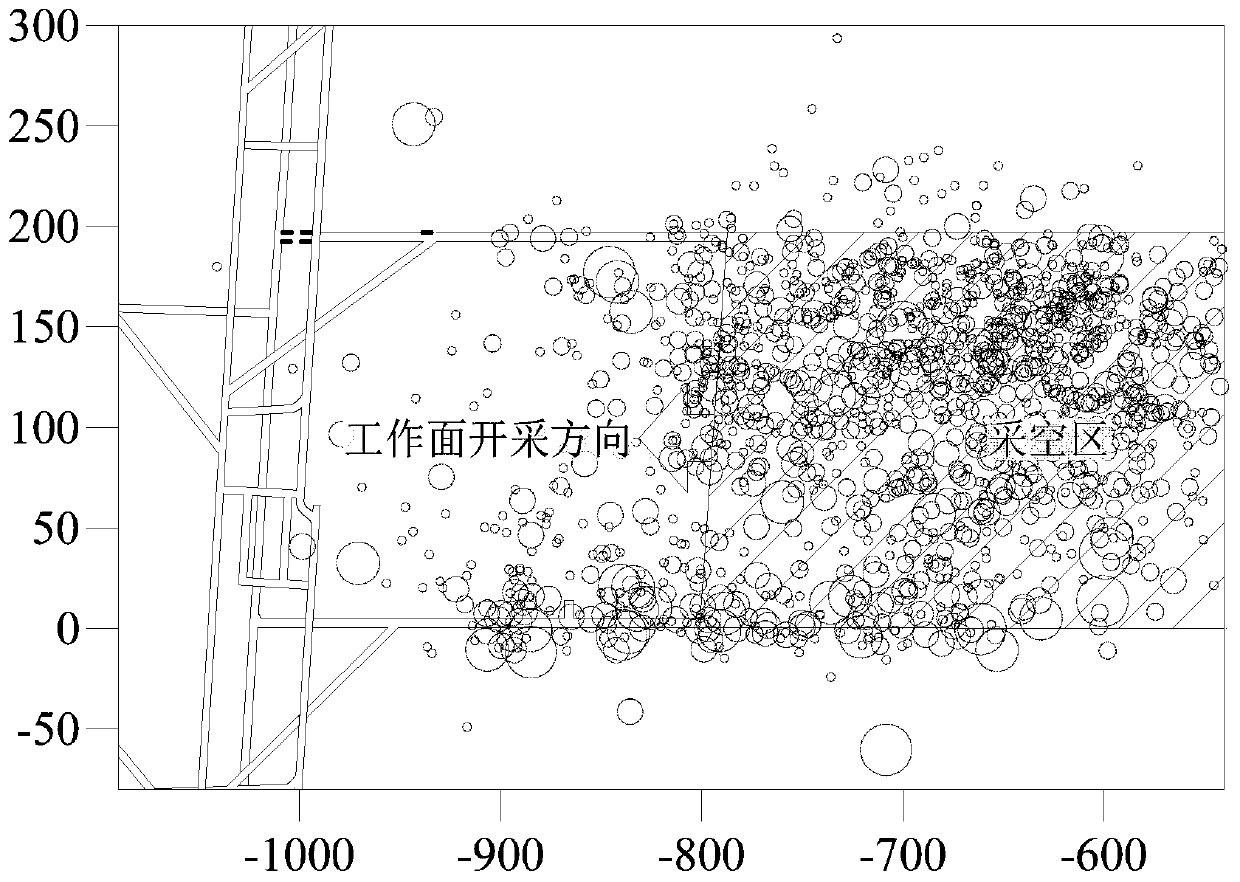

[0049] (1) According to the spatial distribution of microseismic events such as image 3 As shown; the evaluation area is divided into three-dimensional grids, the grid spacing s is 10m, the statistical slip radius r is 30m, and the cumulative deformation energy ε at each grid node is calculated by the cumulative method Ei and coal-rock loading elapsed time Δt i , and then using the interpolation calculation method, it can be obtained as follows Figure 4 The spatial distribution of cumulative deformation energy and Figure 5 The spatial distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com