Composite bactericide for oilfield reverse flooding, and preparation method thereof

A compound fungicide and oil field technology, which is applied in the direction of botany equipment and methods, biocide, disinfectant, etc., and can solve the problem of large usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

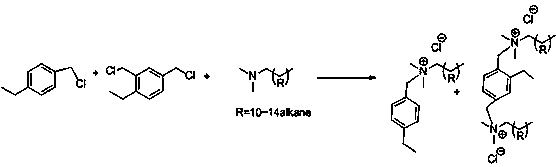

[0024] First synthesize N-alkyl diquaternary ammonium salt:

[0025] Will C 14 330 kilograms of alkyl dimethyl tertiary amines, 70 kilograms of ethyl benzyl chloride, 100 kilograms of ethyl benzyl dichloride, 200 kilograms of ethanol and 300 kilograms of water are inhaled in the reactor. When the temperature reaches 58 degrees Celsius, the steam valve is closed to stop heating, and the heat preservation reaction is carried out for 5 hours. At the end of the heat preservation, send samples for analysis. In the fungicide obtained, the content of quaternary ammonium salts should be ≥50%, and the content of free amines should be ≤1.5%. After passing the analysis, the temperature should be lowered.

[0026] Add 400 kg of 50% N-alkyl bis-quaternary ammonium salt and 600 kg of 70% dodecyl dimethyl benzyl ammonium chloride successively in the mixing tank, stir for 30 minutes after adding all the raw materials, and obtain the compound fungicide for oilfield reinjection water .

Embodiment 2

[0028] Add 300 kg of 50% N-alkyl bis-quaternary ammonium salt and 700 kg of 70% dodecyl dimethyl benzyl ammonium chloride in sequence in the mixing tank. After adding all the raw materials, stir for 30 minutes to prepare the compound fungicide for oilfield reinjection water .

Embodiment 3

[0030] Add 350 kg of 50% N-alkyl bis-quaternary ammonium salt and 650 kg of 70% dodecyl dimethyl benzyl ammonium chloride in sequence in the mixing tank. After adding all the raw materials, stir for 30 minutes to prepare the compound fungicide for oilfield reinjection water .

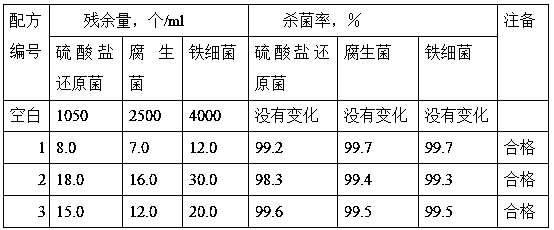

[0031] The water used for bactericidal performance evaluation in Examples 1~3 is the reinjection water of a joint station in Daqing. The evaluation method is operated according to the standard of SY / T0532-2012 oil field injection water bacterial analysis method extinction dilution method. The above examples are performed at a dosage concentration of 8mg The effect of / l is shown in the following table:

[0032]

[0033] It can be seen from the above table that the product obtained in the present invention has a strong bactericidal effect, can effectively remove sulfate-reducing bacteria, iron bacteria, and saprophytic bacteria in oilfield refill water, and has a simple preparation method, low product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com