Preparation method for gliadin-chitosan condensate

A gliadin and chitosan technology, applied in food science, food ingredients, applications, etc., can solve the problem of protein loading rate and rheological properties not being optimal, and achieve extended application scope and effect, elastic modulus The effect of increasing the volume and viscosity modulus and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

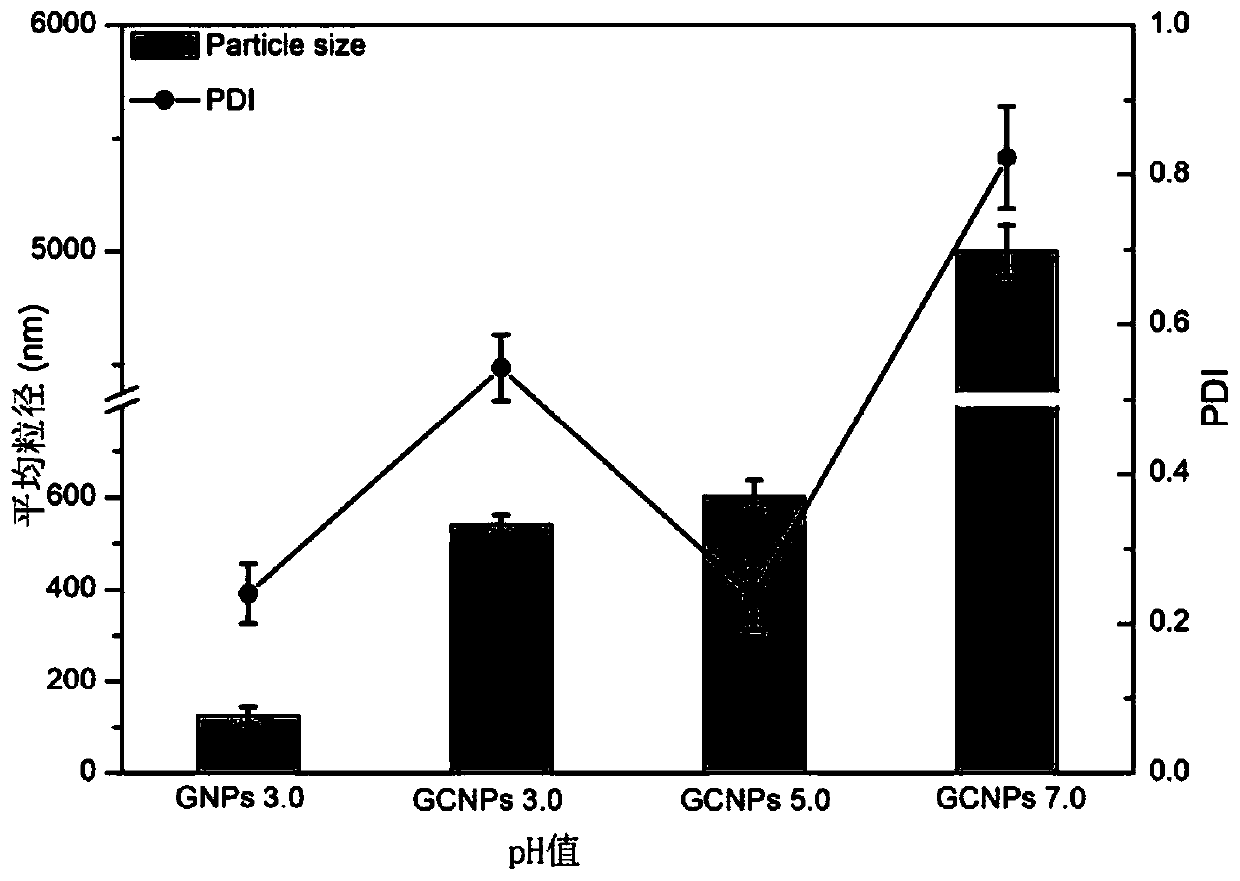

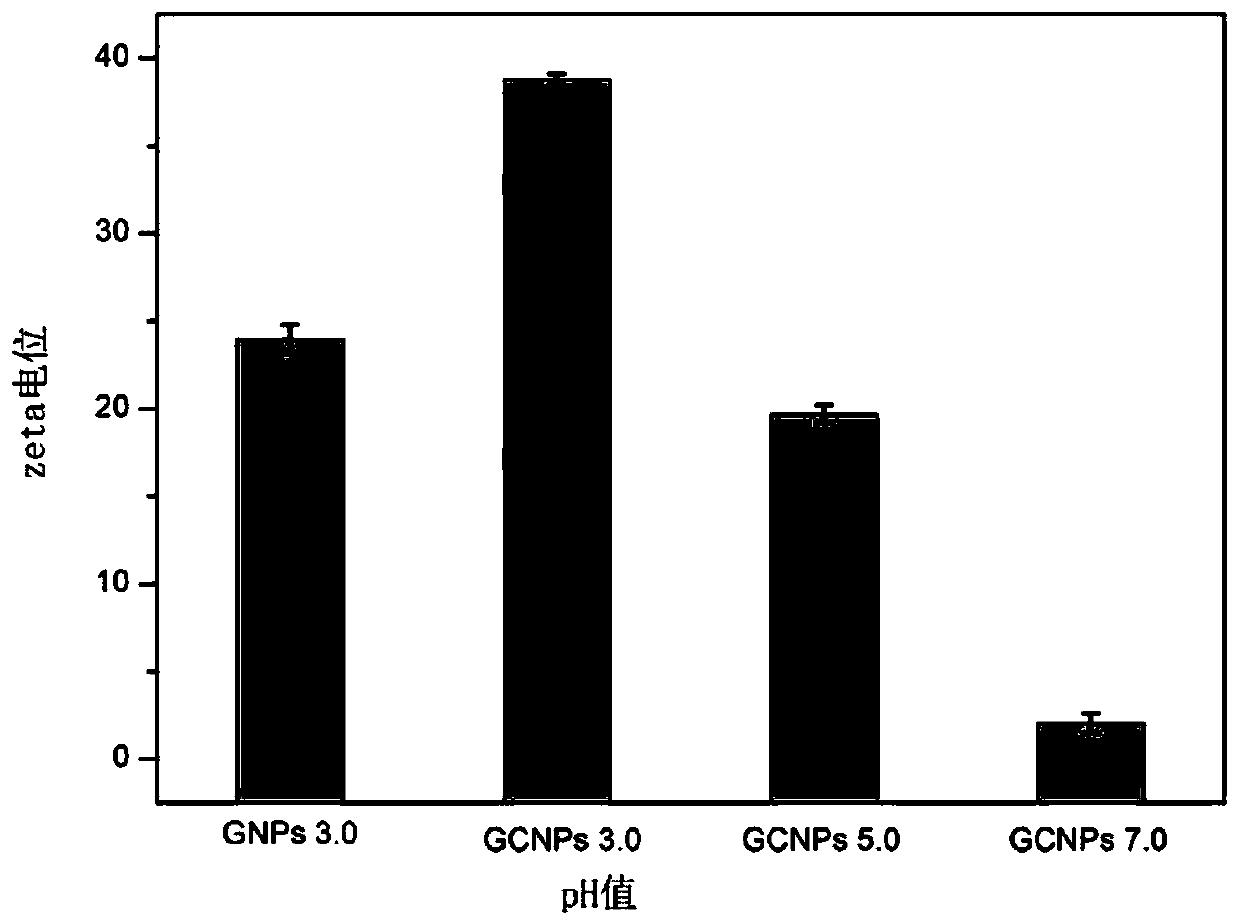

[0031] The preparation of gliadin-chitosan aggregate (coacervate) comprises the following steps:

[0032] (1) Preparation of gliadin solution (Gliadin): Weigh a certain amount of Gliadin sample, dissolve it in 75% (v / v) ethanol solution, and stir it with a magnetic stirrer at a medium speed at room temperature to make it fully Dissolve, prepare Gliadin stock solution with a concentration of 2% (w / v), and store in cold storage.

[0033] (2) Configuration of chitosan (CS) solution: Weigh a certain mass of CS, dissolve it in 1% (w / v) acetic acid, stir it with a magnetic stirrer at a medium speed for 15 minutes at room temperature, and then put it in the refrigerator to refrigerate Overnight, in order to promote the hydration of CS, a CS stock solution with a concentration of 0.1% (w / v) was prepared and stored in cold storage.

[0034] (3) Mix the two stock solutions: take 10ml of Gliadin solution, place it on a magnetic stirrer and stir (normal temperature, medium speed), then q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com