A kind of preparation technology of supporting ring for aerospace equipment

A preparation process and a technology for a support ring, which is applied in the field of the preparation process of a support ring for aerospace equipment, can solve the problems of low pressure resistance, hazards, potential safety hazards of fuel leakage and economic losses, and can avoid tilting, ensure sealing, improve The effect of flame retardant safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

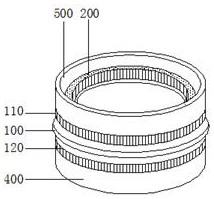

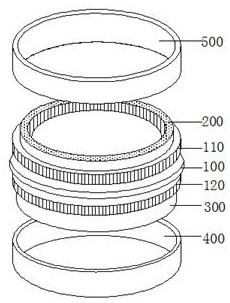

[0023] The invention provides a preparation process of a support ring for aerospace equipment, which can improve the resistance of the support ring, facilitate load-bearing flame retardancy, and have good sealing performance. Please refer to Figure 1-3 , including a capsule ring 100, a top ring 200, a bottom ring 300, a bottom support sleeve 400 and a top support sleeve 500;

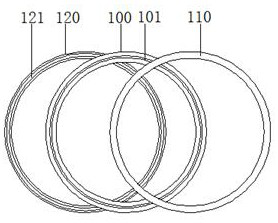

[0024] see again image 3 The outer wall of the capsule ring 100 has a capsule ring groove 101. Specifically, the top and bottom of the capsule ring 100 are provided with a capsule ring groove 101. The capsule ring groove 101 is convenient for connecting with the convex ring 121. The top of the capsule ring 100 contacts the main ring. 110 , the bottom of the bladder ring 100 contacts the secondary ring 120 , the bottom of the main ring 110 and the top of the secondary ring 120 are integrally formed with a protruding ring 121 , and the protruding ring 121 is buckled with the bladder ring groove 101 .

...

Embodiment

[0038] Step 1: Main material preparation: select silicone rubber: 47 parts; polyoxymethylene: 33 parts; polyolefin insulating material: 3 parts; release agent: 2 parts; flame retardant: 5 parts; Mechanically mix, the speed of the mixer motor is 2500r / min, the mixing time is 30min, the temperature during mixing is 190°C-230°C, and the rubber sheet is obtained after cooling;

[0039] Step 2: Preparation of ingredients: Proportioning polyvinyl chloride resin, polyester, plasticizer, stabilizer, and antioxidant, weighing the materials, the ratio is 32:52:13:2.5:0.5, and using mechanical mixing , the mixing time is 25min, and the mixing temperature is 130°C. The preparation of the mixture is protected by high-purity nitrogen under a fully closed loop mirror, which reduces the possibility of oxygenation of the mixture during the preparation process, ensures the purity of the material, and prevents the material from becoming dirty. , to ensure that the ingredients have no difference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com