Colorful environment-friendly double-sided waterproof and sun-proof airtight net clamping cloth and preparation method thereof

A technology of mesh cloth and air tightness, applied in the field of mesh cloth, can solve the problems of reducing product quality, poor air tightness, environmental protection performance, weather resistance and gloss retention performance, etc., so as to improve flame retardant safety. good effect of resistance to acid and alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

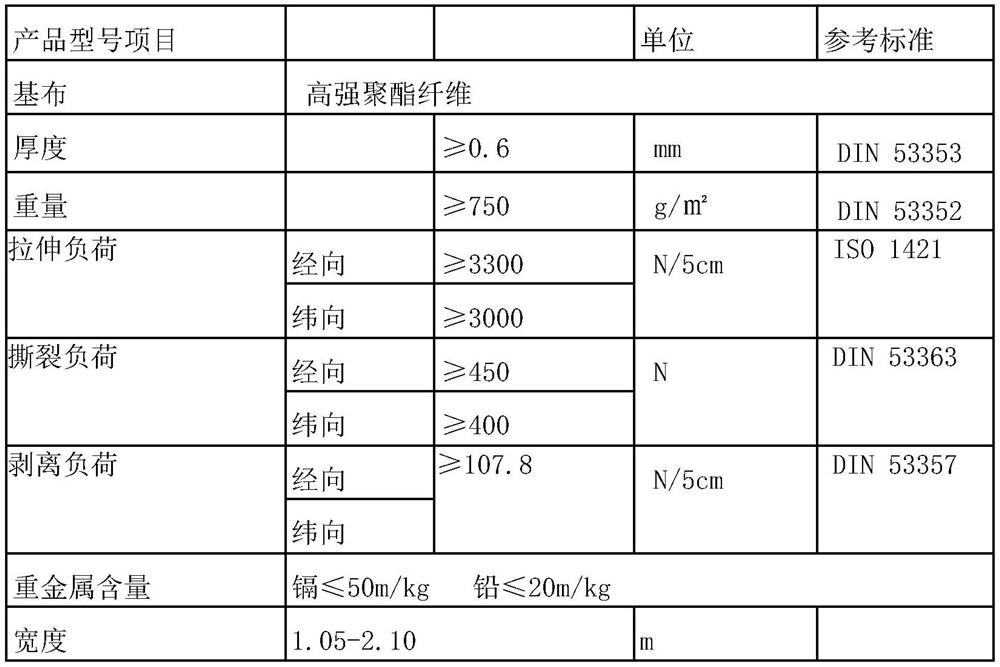

Image

Examples

Embodiment 1

[0032] The colorful, environmentally friendly, double-sided, waterproof, sun-proof, and air-tight mesh clip includes a clip mesh, and the top and bottom surfaces of the clip mesh are laminated with a PVC film at high temperature.

[0033] The PVC film includes the following raw materials by mass fraction: suspension method-polyvinyl chloride resin powder PVC 75 parts, diisononyl phthalate DINP 40 parts, dioctyl adipate DOA 11.5 parts, epoxidized soybean oil 1.5 parts of EPO, 0.22 parts of ultraviolet absorber UV-P, 0.11 parts of antioxidant 1076, 1.5 parts of barium zinc liquid stabilizer BZ, 3.75 parts of antimony trioxide, 9.37 parts of magnesium hydroxide, and 3.3 parts of organic pigments.

[0034] The production of the PVC film includes the following steps:

[0035] 1. To prepare materials, mix suspension method-polyvinyl chloride resin powder PVC 75 parts, diisononyl phthalate DINP 40 parts, dioctyl adipate DOA 11.5 parts, epoxidized soybean oil EPO 1.5 parts, ultraviole...

Embodiment 2

[0057] The colorful, environmentally friendly, double-sided, waterproof, sun-proof, and air-tight mesh clip includes a clip mesh, and the top and bottom surfaces of the clip mesh are laminated with a PVC film at high temperature.

[0058] The PVC film includes the following raw materials by mass fraction: suspension method-polyvinyl chloride resin powder PVC 79 parts, diisononyl phthalate DINP 42 parts, dioctyl adipate DOA 12 parts, epoxy soybean oil EPO 1.6 parts, ultraviolet absorber UV-P 0.23 parts, antioxidant 1076 0.12 parts, barium zinc liquid stabilizer BZ 1.58 parts, antimony trioxide 3.94 parts, magnesium hydroxide 9.84 parts, organic pigments 3.5 parts.

[0059] The production of the PVC film includes the following steps:

[0060] 1. To prepare materials, mix suspension method-polyvinyl chloride resin powder PVC 79 parts, diisononyl phthalate DINP 42 parts, dioctyl adipate DOA 12 parts, epoxidized soybean oil EPO 1.6 parts, ultraviolet absorber 0.23 parts of UV-P, 0...

Embodiment 3

[0082] The colorful, environmentally friendly, double-sided, waterproof, sun-proof, and air-tight mesh clip includes a clip mesh, and the top and bottom surfaces of the clip mesh are laminated with a PVC film at high temperature.

[0083] The PVC film includes the following raw materials by mass fraction: suspension method-polyvinyl chloride resin powder PVC 77 parts, diisononyl phthalate DINP 41 parts, dioctyl adipate DOA 11.8 parts, epoxidized soybean oil EPO 1.55 parts, ultraviolet absorber UV-P 0.225 parts, antioxidant 1076 0.115 parts, barium zinc liquid stabilizer BZ 1.54 parts, antimony trioxide 3.8 parts, magnesium hydroxide 9.55 parts, organic pigments 3.4 parts.

[0084] The production of the PVC film includes the following steps:

[0085] 1. To prepare materials, mix suspension method-polyvinyl chloride resin powder PVC 77 parts, diisononyl phthalate DINP 41 parts, dioctyl adipate DOA 11.8 parts, epoxidized soybean oil EPO 1.55 parts, UV absorption 0.225 parts of U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com