Water-based nano thermal insulation coating and preparation method thereof

A nano-coating technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of insufficient adhesion between coatings and equipment pipelines, paint detachment, influence of thermal insulation effect, etc., and achieve excellent adhesion performance. , Improve adhesion, excellent thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

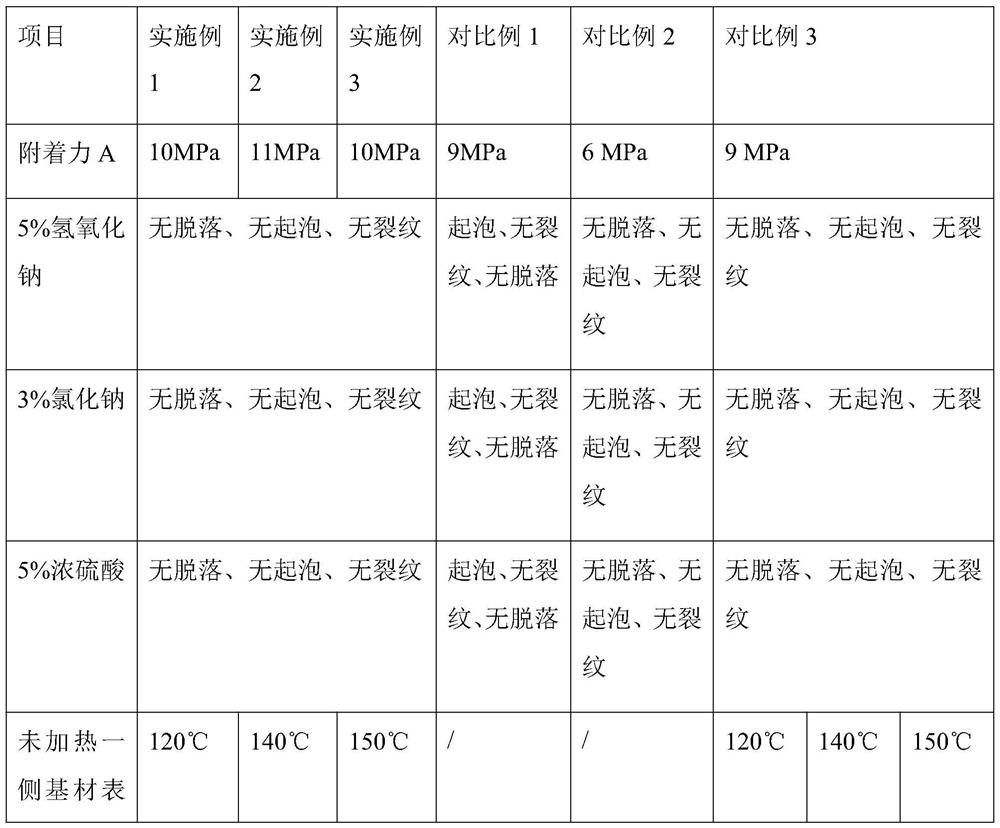

Embodiment 1

[0036] A preparation method of water-based nano thermal insulation coating, comprising the following steps:

[0037] (1) Take sodium hydroxide and tetrahydrofuran, mix well, the concentration of the mixed solution is 4mol / 11L, add trifluoroethanol under nitrogen atmosphere, react at 28°C for 1.2h, cool down to 0°C, add pentafluorostyrene, tetrahydrofuran mixed solution, The concentration of the mixed solution is 2mol / 3L, continue to react for 1h, heat up to 70°C and reflux for 18h, cool after reaction, quench with ice water, extract the organic phase, wash with saturated brine, and purify to obtain the fluorine monomer. The molar ratio of the pentafluorostyrene, trifluoroethanol and sodium hydroxide is 1:1:2.

[0038] Take the emulsifier and deionized water, mix them evenly, and obtain the emulsified aqueous solution;

[0039] Take 1 / 2 amount of emulsified aqueous solution, 1 / 2 amount of ammonium persulfate, and 2 / 3 amount of comonomer, and mix them evenly to obtain solution ...

Embodiment 2

[0049] A preparation method of water-based nano thermal insulation coating, comprising the following steps:

[0050] (1) Take sodium hydroxide and tetrahydrofuran, mix well, the concentration of the mixed solution is 4mol / 11L, add trifluoroethanol under nitrogen atmosphere, react at 29°C for 1.1h, cool down to 0°C, add pentafluorostyrene, tetrahydrofuran mixed solution, The concentration of the mixed solution is 2mol / 3L, continue to react for 1.1h, heat up to 72°C and reflux for 17h, cool after reaction, quench with ice water, extract the organic phase, wash with saturated brine, and purify to obtain fluorine monomer. The molar ratio of the pentafluorostyrene, trifluoroethanol and sodium hydroxide is 1:1:2.

[0051] Take the emulsifier and deionized water, mix them evenly, and obtain the emulsified aqueous solution;

[0052] Take 1 / 2 amount of emulsified aqueous solution, 1 / 2 amount of ammonium persulfate, and 2 / 3 amount of comonomer, and mix them evenly to obtain solution A;...

Embodiment 3

[0062] A preparation method of water-based nano thermal insulation coating, comprising the following steps:

[0063] (1) Take sodium hydroxide and tetrahydrofuran, mix well, the concentration of the mixed solution is 4mol / 11L, add trifluoroethanol under nitrogen atmosphere, react at 30°C for 1h, cool down to 0°C, add pentafluorostyrene, tetrahydrofuran mixed solution, mix The concentration of the solution is 2mol / 3L, continue to react for 1.2h, heat up to 75°C and reflux for 16h, cool after reaction, quench with ice water, extract the organic phase, wash with saturated brine, and purify to obtain the fluorine monomer. The molar ratio of the pentafluorostyrene, trifluoroethanol and sodium hydroxide is 1:1:2.

[0064] Take the emulsifier and deionized water, mix them evenly, and obtain the emulsified aqueous solution;

[0065] Take 1 / 2 amount of emulsified aqueous solution, 1 / 2 amount of ammonium persulfate, and 2 / 3 amount of comonomer, and mix them evenly to obtain solution A;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com