Bio-based bright water-based clear topcoat with lotus effect

A lotus leaf effect, bio-based technology, applied in biocide-containing paints, anti-fouling/underwater coatings, coatings, etc., can solve the problems of environmental damage, high surface tension of paint films, low gloss, etc., and achieve improved paint performance. Film hardness, excellent adhesion, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

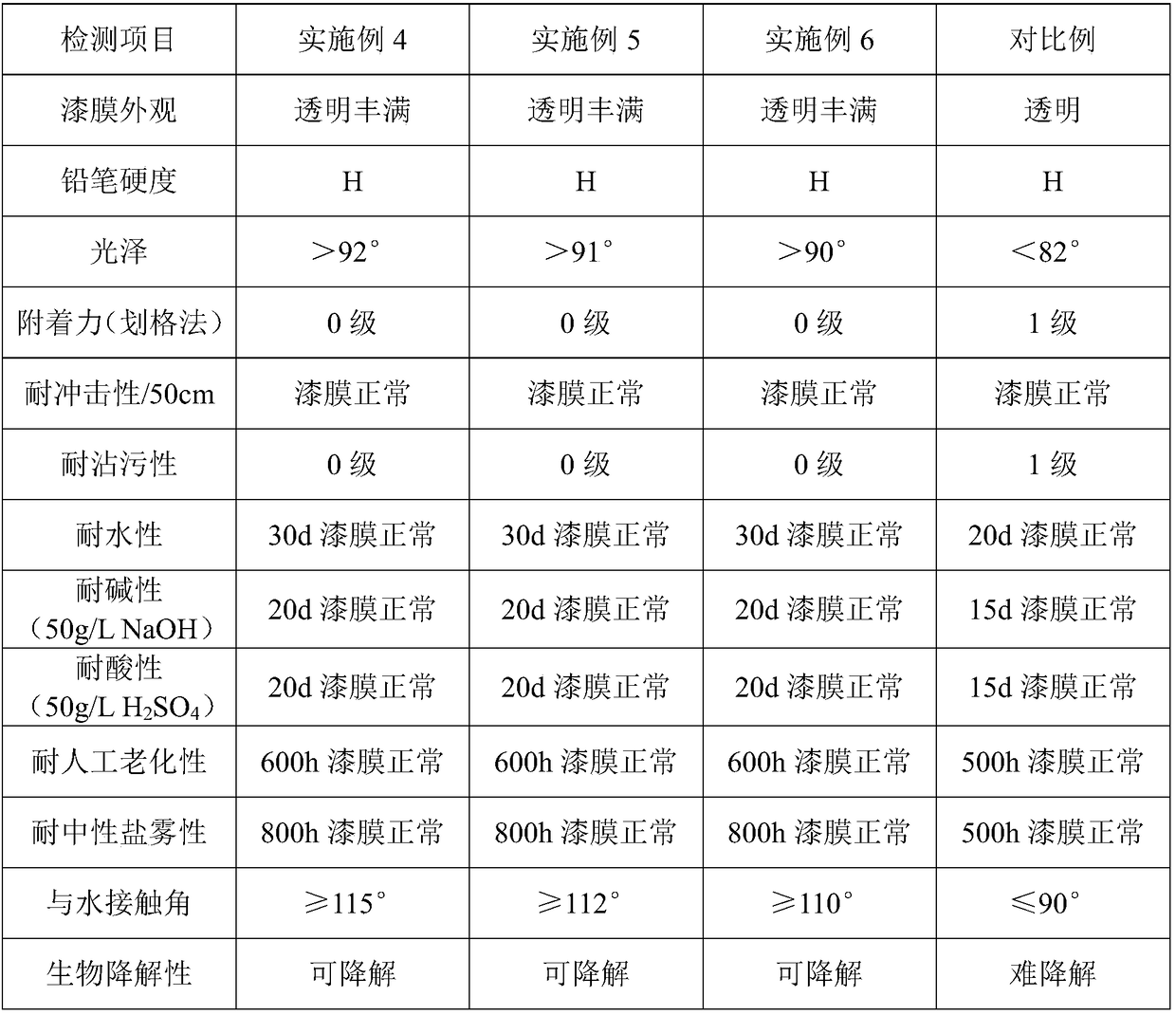

Examples

Embodiment 1

[0027] A bio-based fluorine-modified water-based polyurethane resin X, the preparation steps of which are as follows:

[0028] a) In a four-port reactor equipped with a thermometer, condenser, and agitator, add 3.0 parts of butanediol, 2.0 parts of trimethylolpropane, and 10.0 parts of polytetrahydrofuran diol in sequence, and heat up to 95-110 ℃ vacuum dehydration for 1.5~2.0h;

[0029] b) Cool down to 60-70°C, add 15.0 parts of isophorone diisocyanate, 2.6 parts of dimethylol propionic acid, then dropwise add 0.05 parts of dibutyltin dilaurate, heat up to 80-82°C and react for 2.0-2.5 hours , add 10.0 parts of acetone to adjust the viscosity, lower the temperature to 70°C, add 3.0 parts of castor oil and keep it warm for 1.0h, then add 2.0 parts of hexafluoroisopropanol dropwise, continue the reaction for 1.0h, and check the NCO value. When the values are consistent, lower the temperature below 40°C;

[0030] c) Slowly add 2.0 parts of triethylamine dropwise, stir and re...

Embodiment 2

[0032] A bio-based fluorine-modified water-based polyurethane resin Y, the preparation process of which is as follows:

[0033] a) In a four-port reactor equipped with a thermometer, a condenser, and an agitator, add 4.0 parts of dipropylene glycol, 1.0 parts of trimethylolpropane, and 8.0 parts of polycarbonate diol in sequence, and heat up to 95 ~110℃ vacuum dehydration for 1.5~2.0h;

[0034] b) Cool down to 60-70°C and add 10.0 parts of hexamethylene diisocyanate, 2.0 parts of dimethylol butyric acid, then dropwise add 0.05 parts of dibutyltin dilaurate, heat up to 80-82°C and react for 2.0-2.5 hours , add 10.0 parts of acetone to adjust the viscosity, lower the temperature to 70°C, add 2.5 parts of castor oil and keep it warm for 0.5 hours, then add 2.5 parts of hexafluoroisopropanol dropwise, continue the reaction for 2 hours, and check the NCO value. When consistent, lower the temperature below 40°C;

[0035] c), slowly dropwise add 1.5 parts of triethylamine, after st...

Embodiment 3

[0037] A bio-based fluorine-modified water-based polyurethane resin Z, the preparation steps of which are as follows:

[0038] a) Add 3.0 parts of butanediol, 1.5 parts of glycerin, and 10.0 parts of polycarbonate diol in sequence to a four-port reactor equipped with a thermometer, condenser, and agitator, and heat up to 95-110°C for vacuum dehydration 1.5~2.0h;

[0039]b) Cool down to 60-70°C and add 11.0 parts of isophorone diisocyanate, 1.5 parts of dimethylol butyric acid, then dropwise add 0.05 parts of dibutyltin dilaurate, heat up to 80-82°C for 2.0-2.5 hours , add 10.0 parts of acetone to adjust the viscosity, lower the temperature to 70°C, add 3.0 parts of castor oil and keep it warm for 1 hour, then add 3.0 parts of hexafluoroisopropanol dropwise, continue the reaction for 1.5 hours, and check the NCO value. When consistent, lower the temperature below 40°C;

[0040] c) Slowly add 1.0 parts of triethylamine dropwise, stir and react for 20 minutes, add 53.95 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com