Freight train self-storage energy retarder

A technology for freight trains and deceleration jacks, applied in transportation and packaging, railway car body parts, machines/engines, etc., can solve problems such as energy waste, heat dissipation, etc., and achieve reduced impact peak loads, reduced vibration, and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

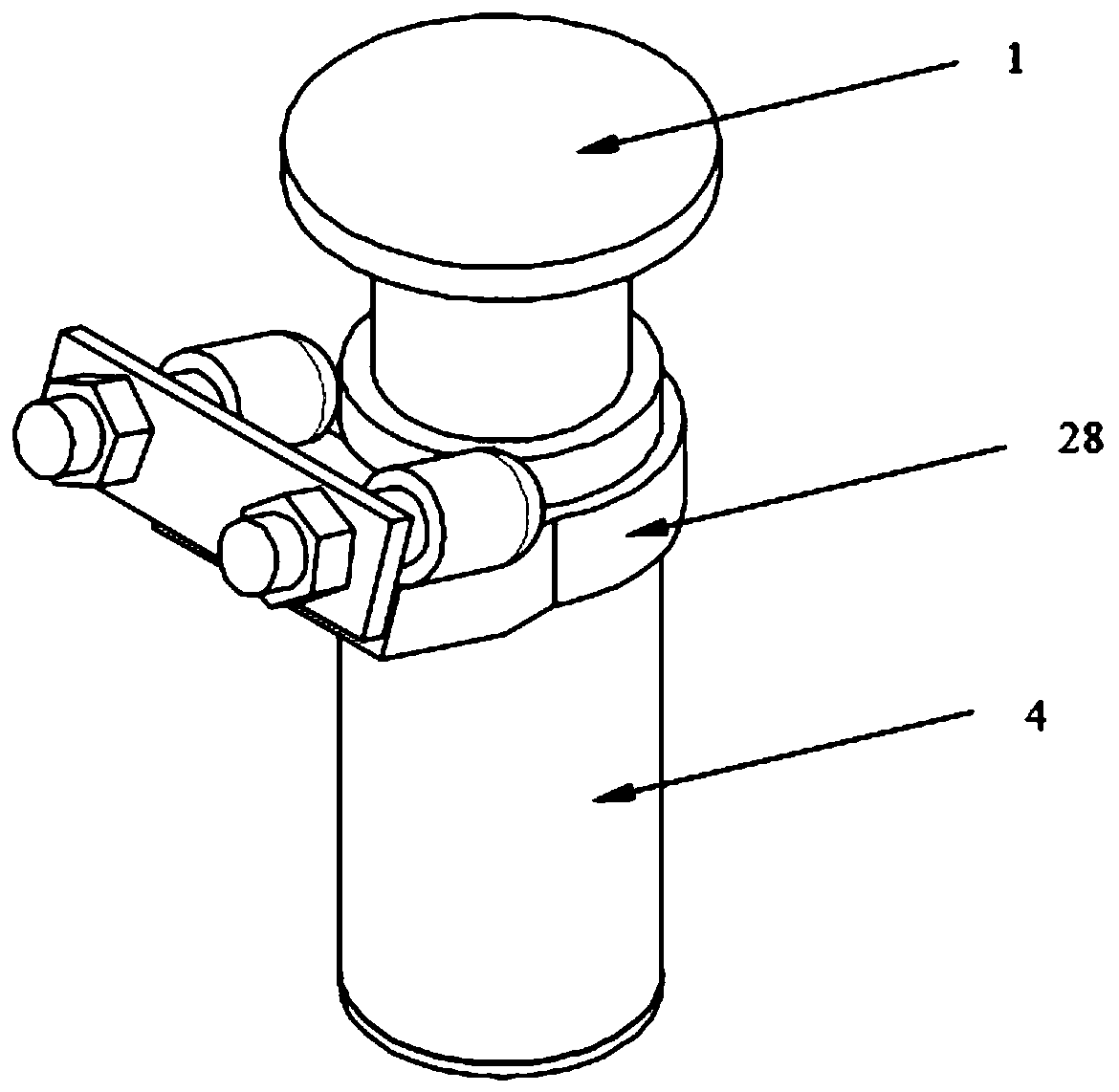

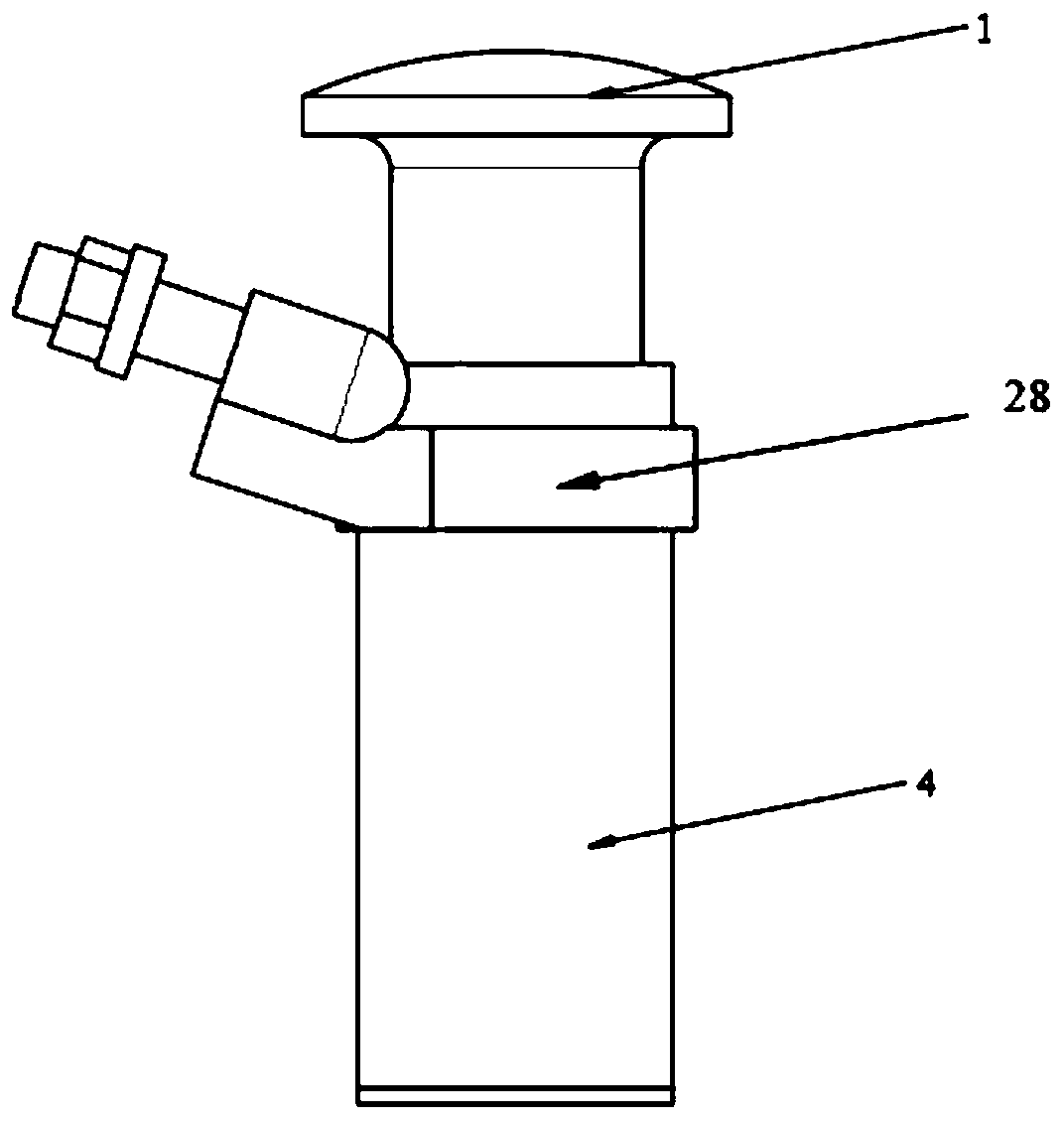

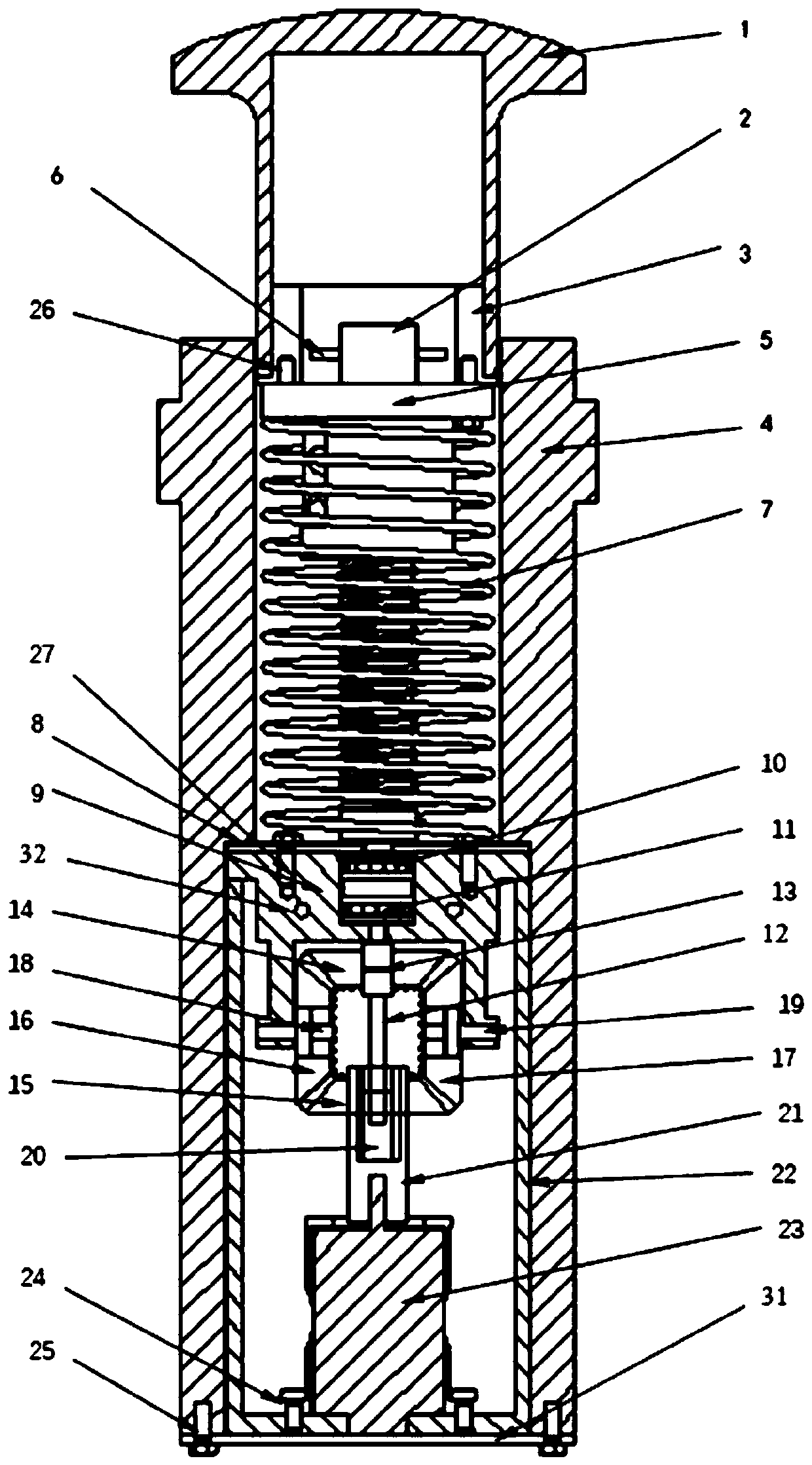

[0045] Combine below Figure 1 ~ Figure 4 The present invention will be described in detail.

[0046] A self-storage energy deceleration roof for freight trains includes a roof 1, a roof base 4 and a fixing device, and also includes a power generation and storage device and a ball screw 2. The ball screw 2 is equipped with a nut 5 , and the nut 5 cooperates with the ball screw 2 to convert the linear motion of the nut 5 into the rotational motion of the ball screw 2 . The top 1 is welded to the nut top connector 3, the nut top connector 3 and the nut 5 are connected by bolt I, the ball screw 2 is covered with a spring 7, the spring 7 is located between the nut 5 and the fixing device, and the spring 7 The diameter is smaller than the diameter of the nut 5 . Described power generation storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com