Synthetic method for high-stability halogen perovskite quantum dot film based on multi-layer coating and used for X-ray imaging

A technology of multi-layer coating and synthesis method, applied in radiation intensity measurement, chemical instruments and methods, luminescent materials, etc., can solve problems such as limitations, and achieve the effects of improving stability, simple and efficient synthesis method, and reducing toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

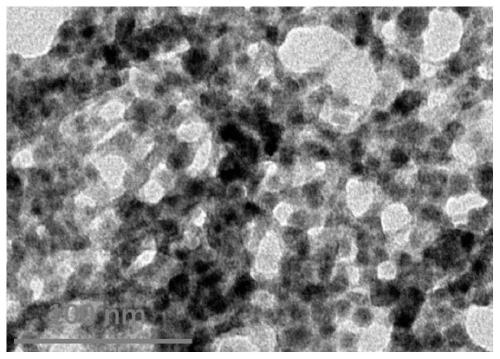

Embodiment 1

[0048] Prepare cesium oleate precursor solution (1.1 mol / L). Add lead bromide (0.138 g), octadecene (10 mL) and oleic acid (0.1 mL) into a 100 mL three-neck round bottom flask, degas for a while and heat to 120o C. After the temperature stabilized, add 3-aminopropyltriethoxysilane (APTES) (1 mL). After APTES is completely dissolved to form a colorless and transparent clear solution, the temperature is raised to 140 o C and the temperature remains constant. The preheated cesium oleate precursor solution (1.5 mL) was instantly injected into the colorless and transparent clear solution. After reacting for 5 s, it was immediately ice-bathed and shaken vigorously to room temperature to obtain all-inorganic perovskite quantum dots. Add 40 mL of ethyl acetate to CsPbBr 3 In the quantum dot solution, the precipitate was collected by centrifugation at 10000 r / min for 1 min, dispersed in 3 mL of toluene solution, and then centrifuged at 8000 r / min for 2 min to collect the quantum dot ...

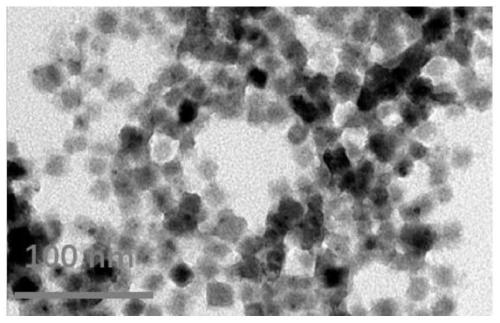

Embodiment 2

[0050] Prepare cesium oleate precursor solution (1.1 mol / L). Add lead bromide (0.138 g), octadecene (10 mL) and oleic acid (0.5 mL) into a 100 mL three-neck round bottom flask, degas for a while and heat to 120 o C. After the temperature stabilized, add 3-aminopropyltriethoxysilane (APTES) (1 mL). After APTES is completely dissolved to form a colorless and transparent clear solution, the temperature is raised to 140 o C and the temperature remains constant. The preheated cesium oleate precursor solution (1.5 mL) was instantly injected into the colorless and transparent clear solution. After reacting for 5 s, it was immediately ice-bathed and shaken vigorously to room temperature to obtain all-inorganic perovskite quantum dots. Add 40 mL of ethyl acetate to CsPbBr 3 In the quantum dot solution, the precipitate was collected by centrifugation at 10000 r / min for 1 min, dispersed in 3 mL of toluene solution, and then centrifuged at 8000 r / min for 2 min to collect the quantum do...

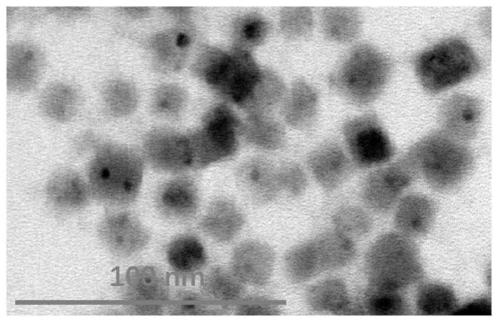

Embodiment 3

[0052] Prepare cesium oleate precursor solution (1.1 mol / L). Add lead bromide (0.138 g), octadecene (10 mL) and oleic acid (1 mL) into a 100 mL three-neck round bottom flask, degas for a while and heat to 120 o C. After the temperature stabilized, add 3-aminopropyltriethoxysilane (APTES) (1 mL). After APTES is completely dissolved to form a colorless and transparent clear solution, the temperature is raised to 140 o C and the temperature remains constant. The preheated cesium oleate precursor solution (1.5 mL) was instantly injected into the colorless and transparent clear solution. After reacting for 5 s, it was immediately ice-bathed and shaken vigorously to room temperature to obtain all-inorganic perovskite quantum dots. Add 40 mL of ethyl acetate to CsPbBr 3 In the quantum dot solution, the precipitate was collected by centrifugation at 10000 r / min for 1 min, dispersed in 3 mL of toluene solution, and then centrifuged at 8000 r / min for 2 min to collect the quantum dot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com