A method for preparing low de value maltodextrin from crushed corn

A maltodextrin and broken corn technology, applied in the direction of fermentation, can solve the problems of increasing post-processing filtration difficulties, post-processing filtration difficulties, and ineffective utilization, etc., and achieves reduction of pre-treatment processes, labor intensity, and viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

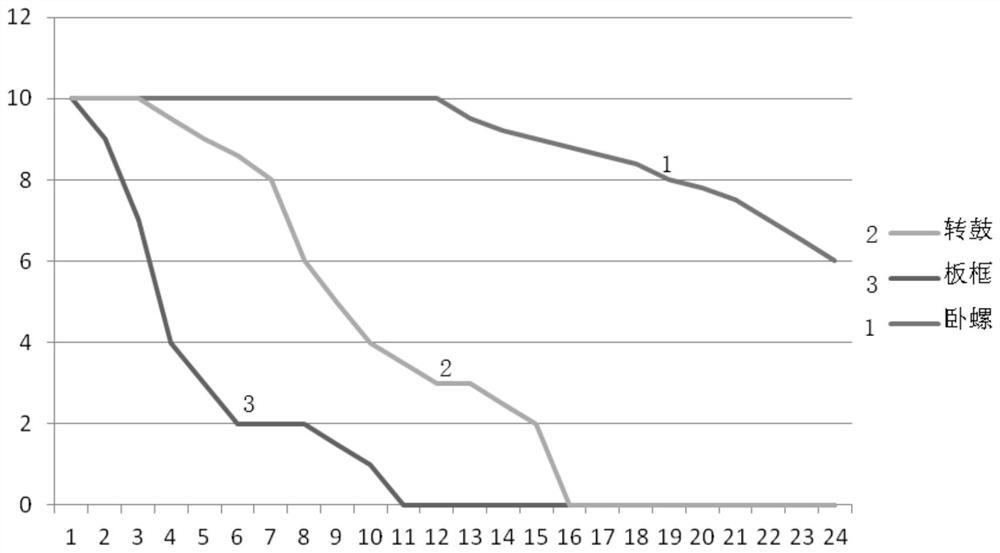

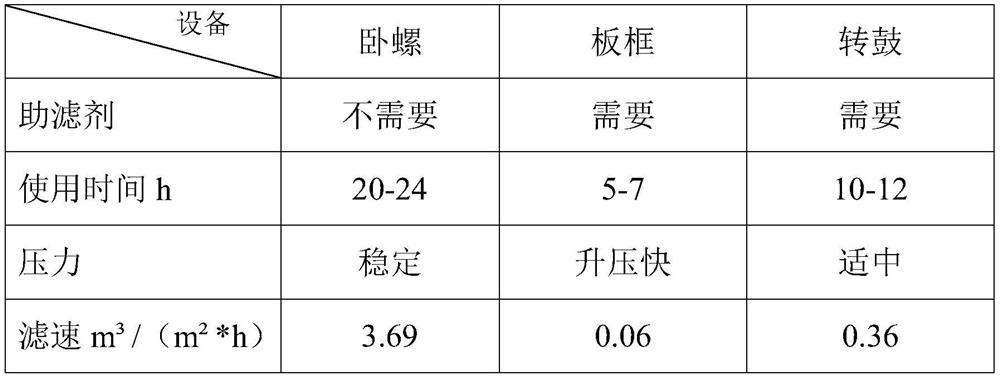

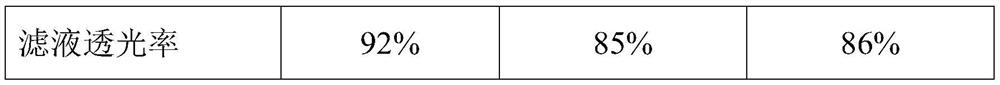

Embodiment 1

[0031] After removing iron and stone from the crushed corn collected in production, crush it, pass through a 400-mesh sieve, add water to adjust the slurry to 28%, adjust the pH value to 5.5-5.8, add high-temperature-resistant amylase 0.38kg / T to dry Base starch; high-pressure steam injector is used, material pressure is 0.45Mpa, injection temperature is 112°C, injection time is 8min, 96°C is maintained for 110min, DE value is controlled at 18-20%; high-pressure steam injector is used to kill enzymes, steam pressure is 0.75Mpa, The material pressure is 0.48Mpa, the temperature of spraying enzyme is 142°C, and the spraying time is 8 minutes; after the enzyme is killed, the liquefied liquid is cooled to 88°C, and the slag is removed by a horizontal screw separator, and the slag is dried to make feed; Amar closed type Filter, the amount of carbon added is 2kg / T dry base sugar, the decolorization temperature is 88°C, and the decolorization time is 25min. The filtered material is tr...

Embodiment 2

[0033] After removing iron and stone from the crushed corn collected in production, crush it, pass through a 400-mesh sieve, add water to adjust the slurry to 25%, adjust the pH value to 5.5-6.0, and add 0.35kg / T of high-temperature-resistant amylase to dry Base starch; using a high-pressure steam injector, the steam pressure is 0.75Mpa, the material pressure is 0.48Mpa, the injection temperature is 112°C, the injection time is 8min, the 97°C is maintained for 100min, and the DE value is controlled at 18%; the high-pressure steam injector is used to kill enzymes, and the steam pressure 0.8Mpa, the material pressure is 0.48Mpa, the enzyme spraying temperature is 140°C, and the enzyme spraying time is 10min; after the enzyme is inactivated, the liquefied liquid is cooled to 86°C, the slag is removed by a horizontal screw separator, and the slag is dried to make feed; Ma closed-type filter, the amount of carbon added is 2.5kg / T dry base sugar, the decolorization temperature is 85°...

Embodiment 3

[0035]After removing iron and stone from the crushed corn, crush it, pass through a 400-mesh sieve, add water to adjust the slurry to 21%, adjust the pH value to 5.2-5.5, and add 0.32kg / T dry base starch of high-temperature-resistant amylase; High-pressure steam ejector, steam pressure 0.8Mpa, material pressure 0.5Mpa, injection temperature 112°C, injection time 8min, 98°C for 100min, control DE value 15-20%; use high-pressure steam ejector to kill enzymes, steam pressure 0.8Mpa , the material pressure is 0.5Mpa, the spraying temperature is 138°C, and the spraying time is 10 minutes; after the enzyme is killed, the liquefied liquid is cooled to 85°C, and the slag is removed by a horizontal screw separator, and the slag is dried to make feed; Amar airtight Type filter, the amount of carbon added is 2.2kg / T dry base sugar, the decolorization temperature is 85°C, and the decolorization time is 30min. The filtered material is transparent, carbon-free, and impurity-free, and the lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com