Welding construction method of cement-based material applied to composite concrete structure

A cement-based material and concrete technology, applied in cement production, building construction, construction, etc., can solve the problems of complex connection structure, unreusable components, and unsuitable for large-scale use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

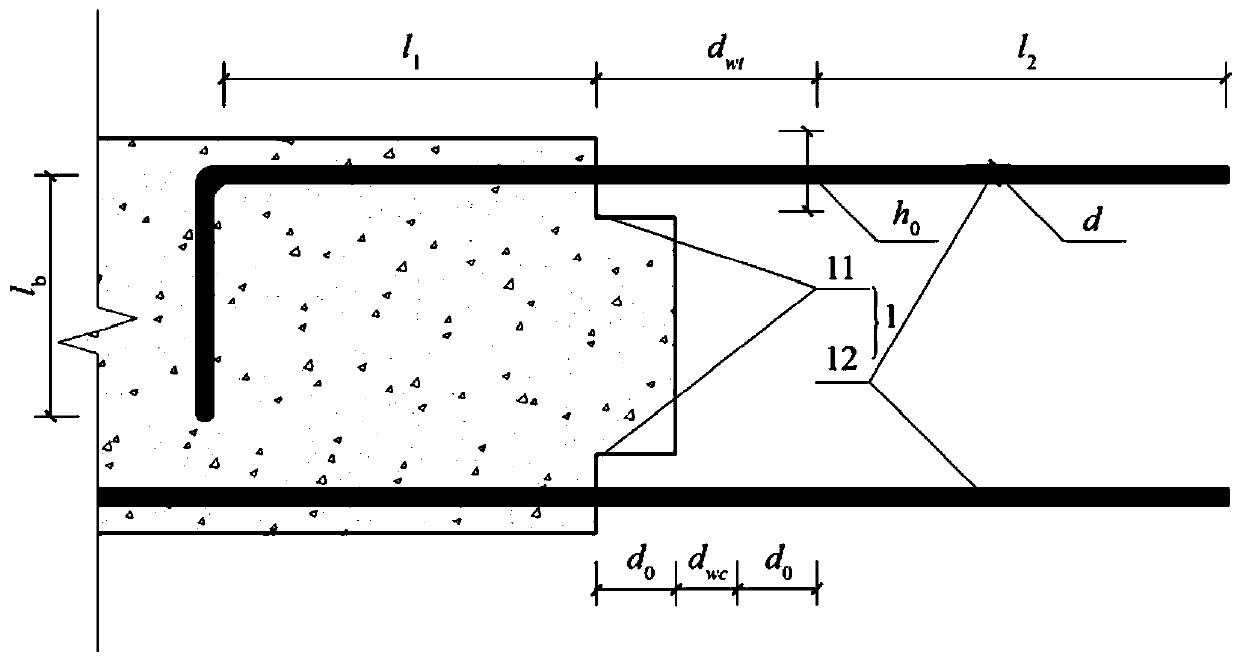

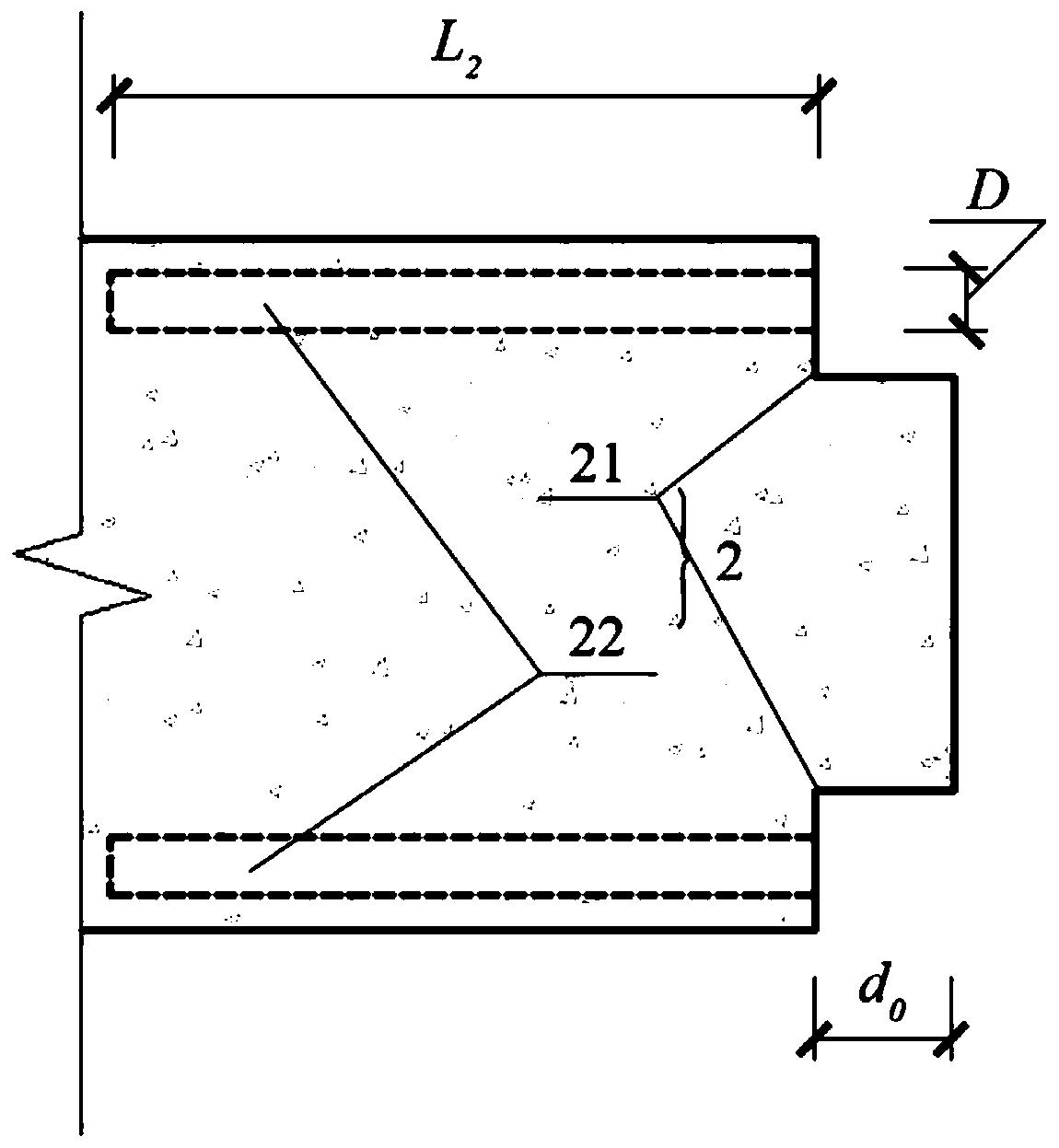

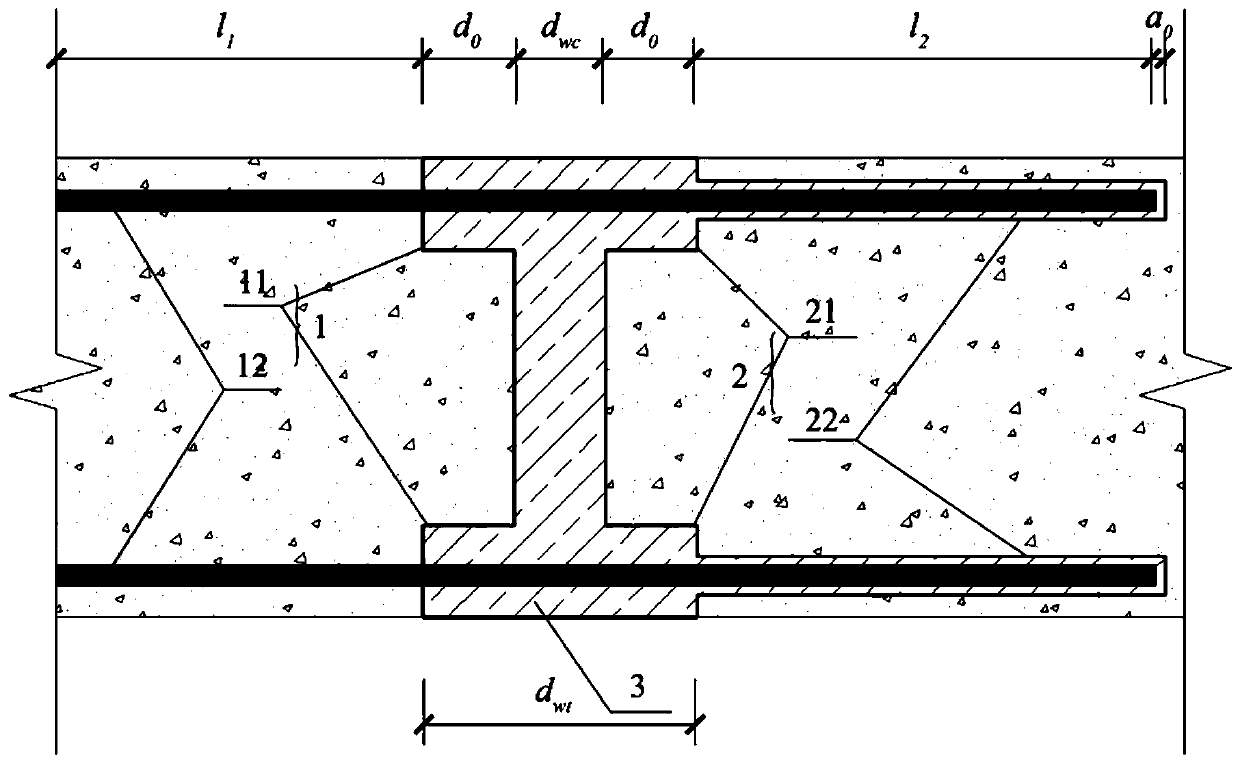

[0198] Production of precast concrete elements at the factory or on site, e.g. image 3 As shown, the first part of precast concrete components (such as figure 1 ) and the second part of precast concrete elements (such as figure 2 ) are precast concrete beam members. Transport and hoist the prefabricated concrete components to the place to be installed, and extend the steel bars passing through the first part of the prefabricated concrete components into the reinforcement channels of the second part of the prefabricated concrete components for fixing. The cement-based material is filled into the gap between the interfaces of adjacent prefabricated concrete components, so that the first part of the prefabricated concrete component and the second part of the prefabricated concrete component are connected and cured. It constitutes concrete beam-beam joint sample 1#.

[0199] Among them, the cross-sectional dimensions of the beams of the first part of the precast concrete memb...

Embodiment 2

[0218] Production of precast concrete elements at the factory or on site, e.g. Figure 5 As shown, the first part of precast concrete components (such as figure 1 ) is the precast concrete column member, the second part of the precast concrete member (such as figure 2 ) is a precast concrete beam member. Among them, the tensile side of the precast concrete beam member protrudes the steel bar, transports and lifts the precast concrete member to the position to be installed, and extends the steel bar passing through the first part of the precast concrete member into the steel bar channel of the second part of the precast concrete member for fixing. The cement-based material is filled into the gap between the interfaces of adjacent prefabricated concrete components, so that the first part of the prefabricated concrete component and the second part of the prefabricated concrete component are connected and cured. It constitutes concrete beam-column joint sample 2#.

[0219] Amo...

Embodiment 3

[0238] Production of precast concrete elements at the factory or on site, e.g. Image 6 As shown, the first part of precast concrete components (such as figure 1 ) and the second part of precast concrete elements (such as figure 2 ) are precast concrete column members. Transport and hoist the prefabricated concrete components to the place to be installed, and extend the steel bars passing through the first part of the prefabricated concrete components into the reinforcement channels of the second part of the prefabricated concrete components for fixing. The cement-based material is filled into the gap between the interfaces of adjacent prefabricated concrete components, so that the first part of the prefabricated concrete component and the second part of the prefabricated concrete component are connected and cured. It constitutes concrete column-column joint sample 3#, which bears axial pressure.

[0239] Among them, the column cross-sectional dimensions of the first part ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com