Comfortable and energy-saving fully assembled adobe house and construction method thereof

A fully assembled, adobe house technology, applied in the direction of building structure, construction, building components, etc., can solve the problems of unfavorable environmental protection and energy saving, poor thermal stability, high labor intensity, etc., to improve the service life and carrying capacity, improve Thermal insulation and moisture retention performance, the effect of improving firmness and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

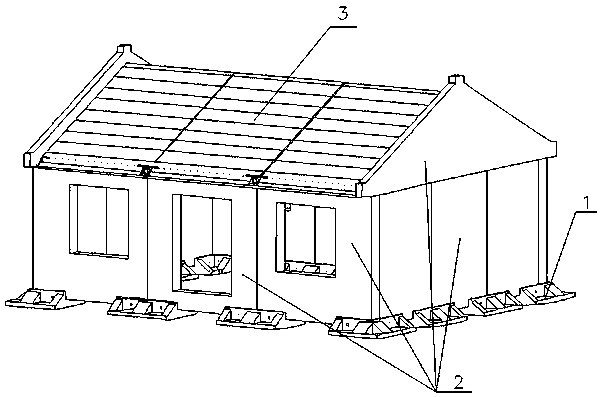

[0066] Example 1 A comfortable and energy-saving fully assembled adobe house

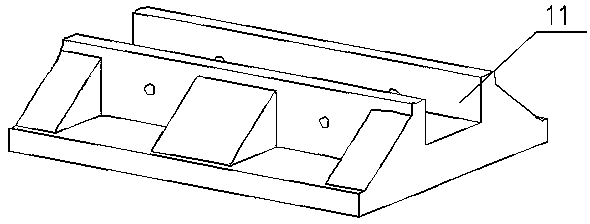

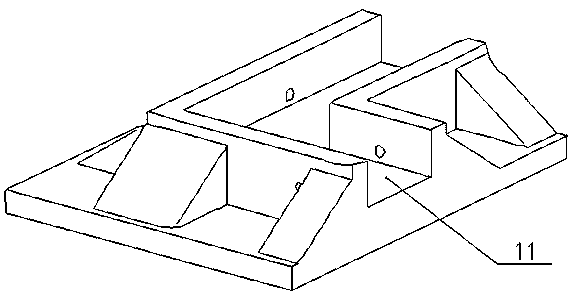

[0067] Such as Figure 1-10 As shown, the present invention provides a comfortable and energy-saving fully assembled adobe house. The house can be single-storey or multi-storey. In this embodiment, the house has three single-storey rooms, including independent foundation 1, mixed adobe wall 2 and prefabricated roof 3; The independent foundation 1, the mixed adobe wall 2 and the prefabricated roof 3 are assembled to form a box structure;

[0068] The independent foundation 1 is set on the foundation; the independent foundation 1 is prefabricated in the factory; the size of the independent foundation 1 is determined according to the bearing capacity of the foundation; the independent foundation 1 is made of concrete; The shape of the foundation 1 is determined according to the shape of the joint of the mixed adobe wall 2, including a long strip foundation and a right-angled foundation; the independent foun...

Embodiment 2

[0086] Example 2 A method for constructing a comfortable and energy-saving fully assembled adobe house

[0087] The present invention provides a method for constructing a comfortable and energy-saving fully assembled adobe house. The method for constructing a comfortable and energy-saving fully assembled adobe house according to the first embodiment includes the following steps:

[0088] Step 1: According to the different bearing capacity of the foundation, the independent foundation made in the factory with different specifications but with the same installation slot; according to the size of the house bay, mixed adobe walls of different standard specifications are prefabricated in the factory, including the front wall of the door, The front wall of the window, the rear wall of the window, the gable and the peak of the gable; according to the room of the house, the required number of prefabricated roofs are made in the factory;

[0089] Step 2: Transport the independent foundation, ...

Embodiment 3

[0097] Example 3 A comfortable and energy-saving fully assembled adobe house

[0098] Such as Figure 16-17 As shown, the difference between this embodiment and Embodiment 1 is that the prefabricated roof 3 includes multiple roofs 36 and a triangular steel structure roof truss 37; the roof 36 has the same internal structure as the mixed adobe wall 2, and both include mixed adobes. And a concrete lattice structure; both sides of the top plate 36 are provided with inclined surfaces 361.

[0099] The triangular steel structure roof truss 37 is arranged on the upper part of the top plate 36; the triangular steel structure roof truss 37 is welded by section steel; the triangular steel structure roof truss 37 includes an upper chord 373, a lower chord 374, a straight tension and compression rod 375, and a diagonal Tension and compression rod 376; the number of the upper chord 373 is two; the tops of the two upper chords 373 are fixedly connected together at an obtuse angle, and the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com