Method of construction of stairs using precast concrete landing slabs and support systems

A technology of prefabricated concrete and support system, which is applied in the direction of stairs, building construction, construction, etc., and can solve problems such as inconvenient connection of spreaders and complicated production of pre-embedded iron parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

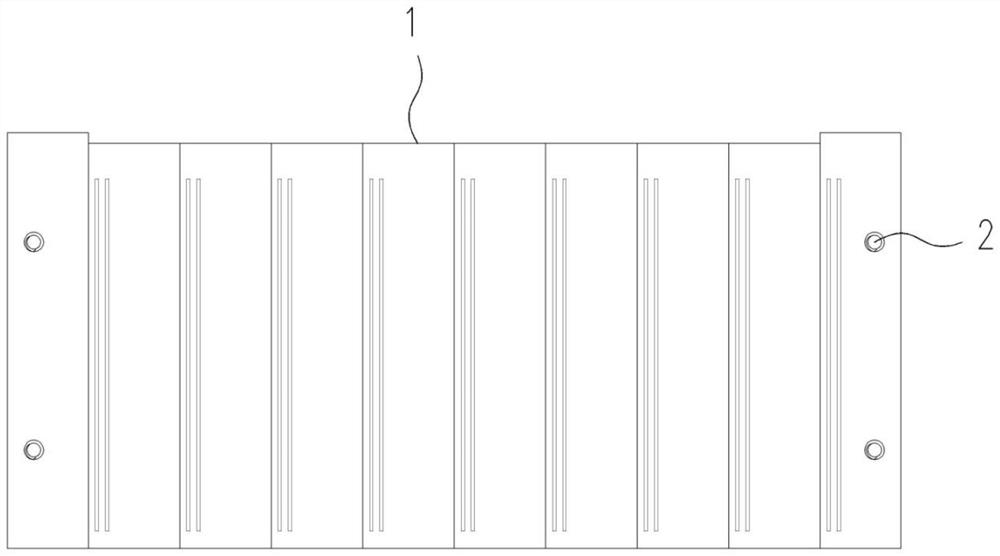

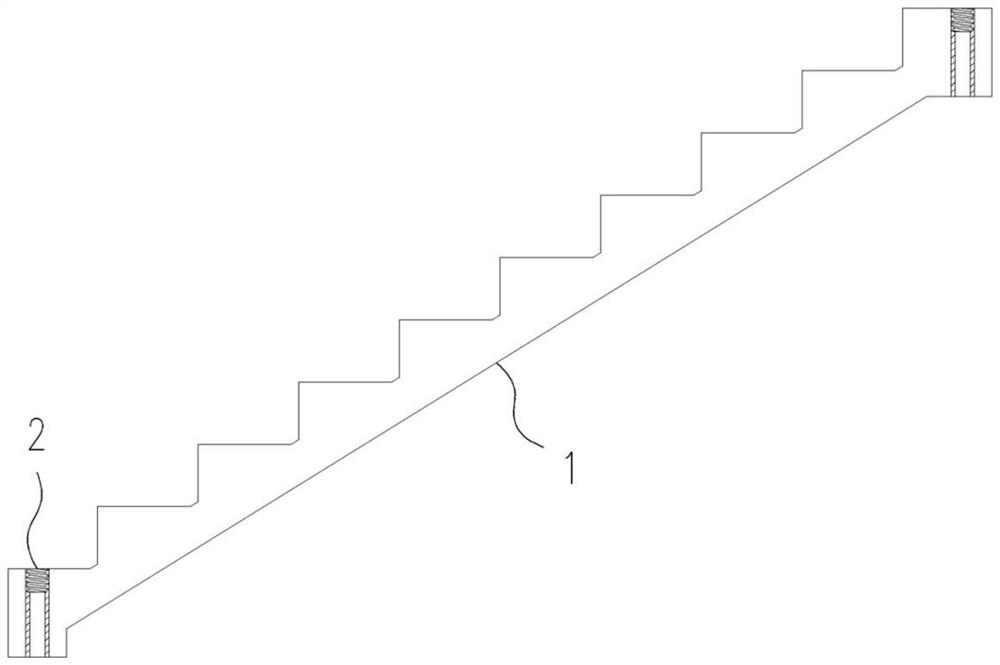

[0072] Methods of stair construction using precast concrete landing slabs and support systems such as Figure 1 to Figure 34 As shown, the construction is carried out by using the prefabricated concrete stair platform 3 and a support system for installing prefabricated concrete stairs, including the following steps, and the following steps are carried out in sequence,

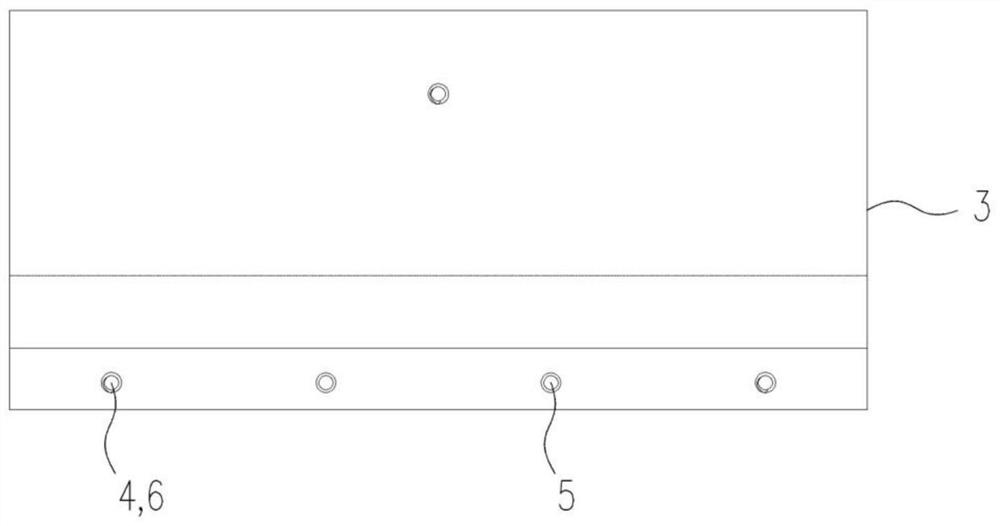

[0073] Step 1. Preparation of precast concrete stair landing slabs

[0074] Such as Figure 3 ~ Figure 7 As shown, prepare the prefabricated concrete stair platform slab 3, set a blind hole tool 6 on the flat plate of the platform slab 3, set a blind hole tool 6 on the lugs at both ends of the stair beam of the platform slab 3, and the blind hole tool 6 adopts a pipe Preparation, the inner wall is provided with a threaded section, and the bottom is blocked; a support groove 4 is provided at the corresponding position at the bottom of the blind hole 6; the bolt hanger can be screwed into the blind hole 6 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com