Bolt-sphere joint type net rack bed-jig and green construction method thereof

A bolt ball and grid technology, applied in pillars, roofs, building components, etc., can solve the problems of occupying large turnover materials, long construction operation period, increasing support, etc., to control construction costs, control construction costs, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

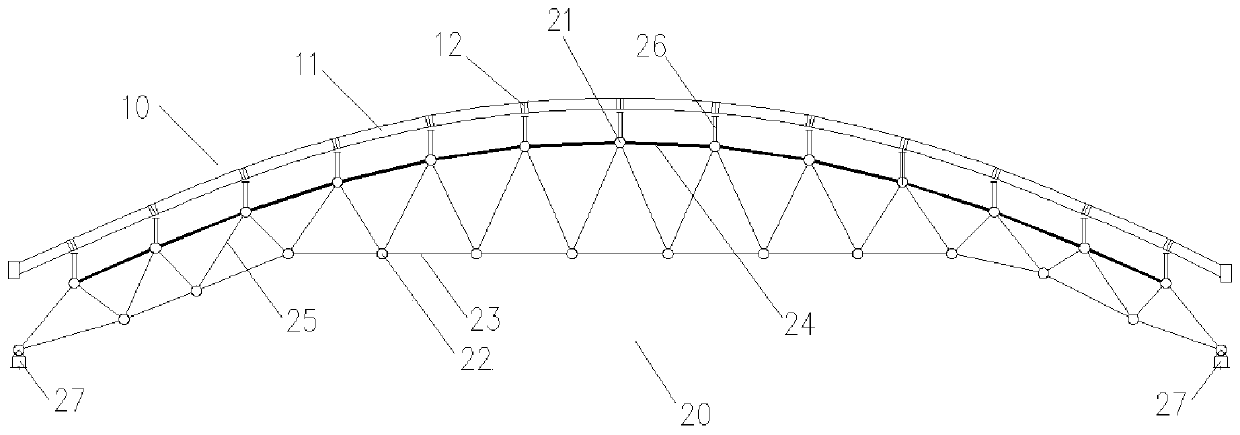

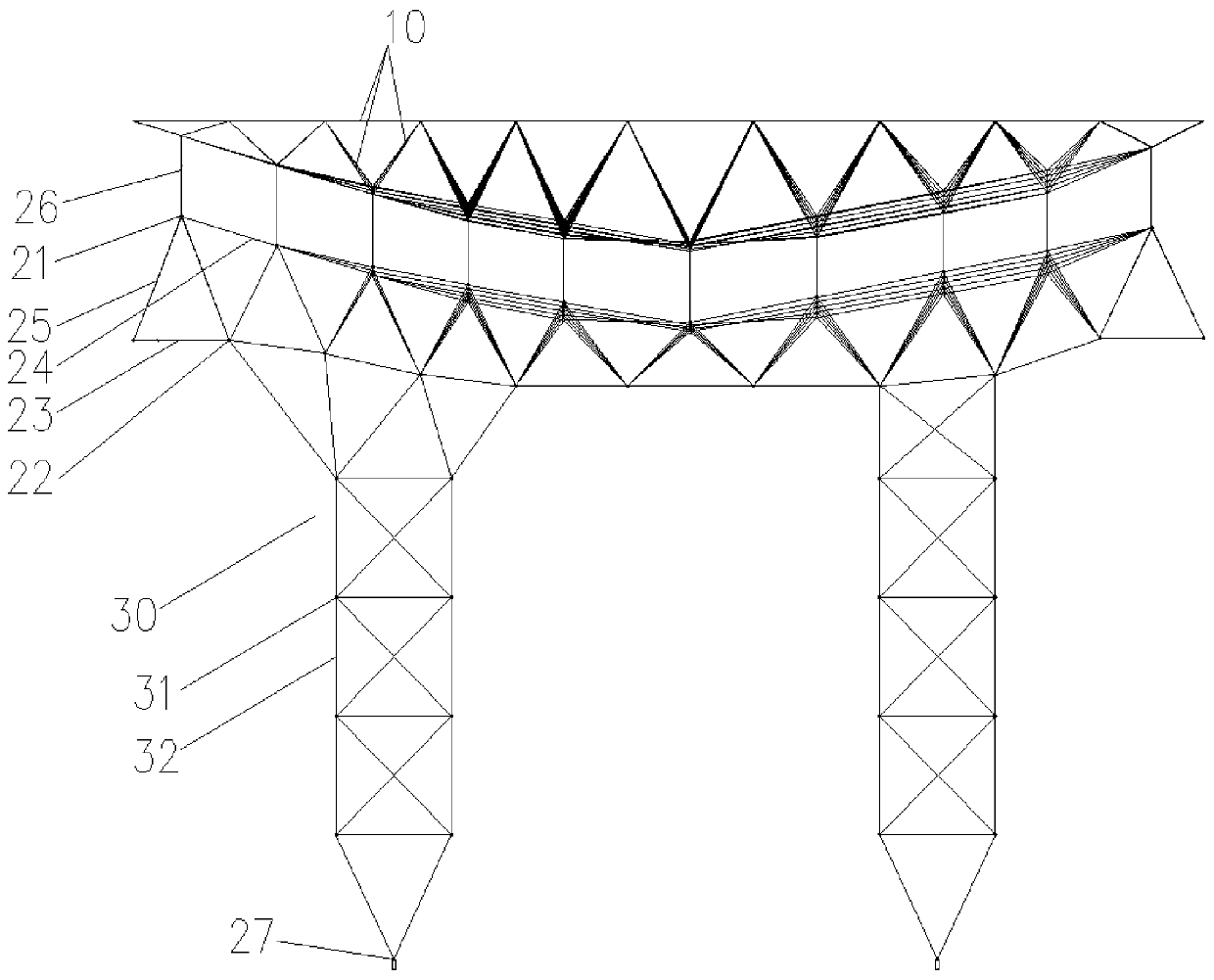

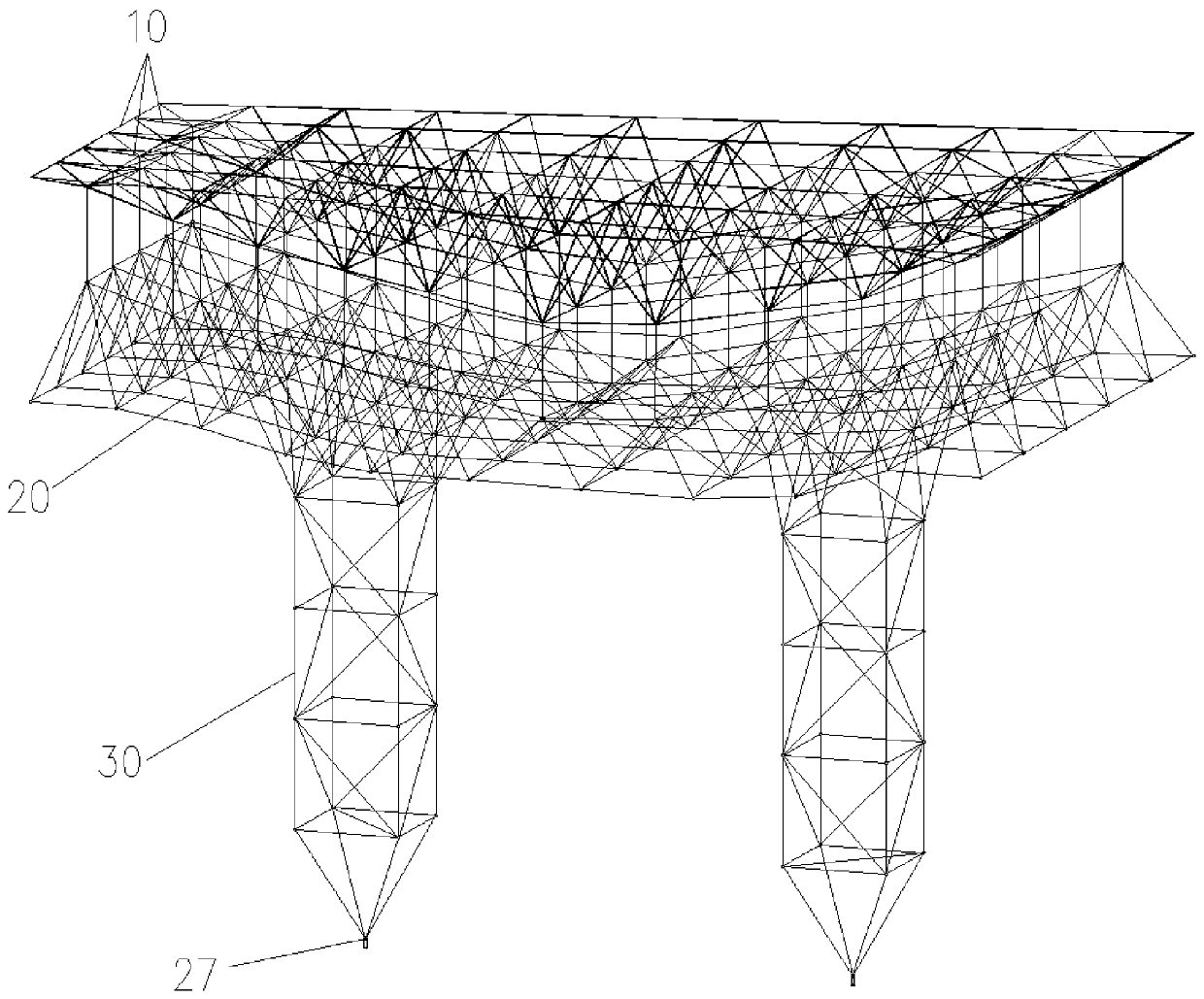

[0055] Such as Figure 1-3 As shown, a bolt ball node type network frame tire frame provided in this embodiment is used as a mold for building a new structure 10, including: a network frame body 20; a plurality of upper string positioning nodes 21 are arranged on the network frame body 20; The newly built structure 10 includes a plurality of connection nodes 12 respectively used for the intersection connection of several main girders 11; each upper chord positioning node 21 is correspondingly arranged directly below a set connection node 12, and is used for positioning and / or The set connection node 12 is supported. Wherein, the connection node 12 is a fixed connection point of several main girders 11 .

[0056] A plurality of connection nodes 12 construct the space curved surface of the new structure 10, and all top chord positioning nodes 21 construct the top chord surface of the grid body 20; the top chord surface and the space curved surface are mutually equidistant curve...

Embodiment 2

[0072] The embodiment of the present invention discloses a green construction method using the above-mentioned bolt ball node type grid tire frame, which includes the following steps:

[0073] S10. Utilize the computer to build the new structure 10 model and the bolt ball node type network frame tire frame model;

[0074] S20. Prepare all components of the bolt ball node grid tire frame according to the bolt ball node grid tire frame model; the non-universal parts in the components are numbered sequentially for rapid identification and assembly on site;

[0075] S30. Assemble the bolted ball node type network frame tire frame on site, locate multiple connection nodes 12 of the new structure 10 based on the upper chord positioning node 21 of the tire frame, hoist the main beam 11 of the new structure 10, and overlap them on the same The ends of several main beams 11 above the upper chord positioning node 21 are fixedly connected to form the connection node 12; after that, each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com