Coal pillar failure method for weakening potential failure surface of remaining coal pillar

A technology of leaving coal pillars and failure surfaces, which is applied in ground mining, earthwork drilling, and testing the strength of materials by applying a stable shear force. It can solve the problems of low safety, increased technical difficulty, and high cost, and achieve material reduction Usage amount, elimination of potential safety hazards, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

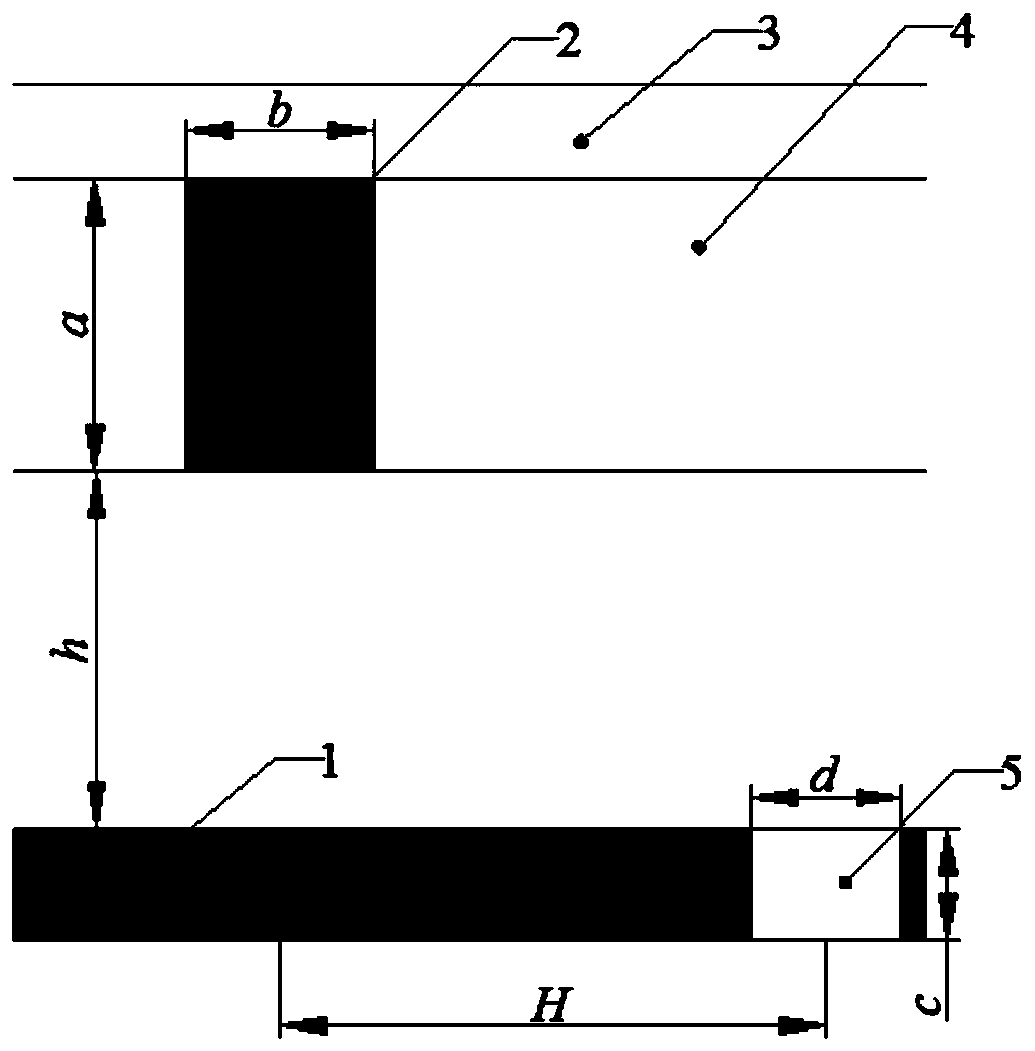

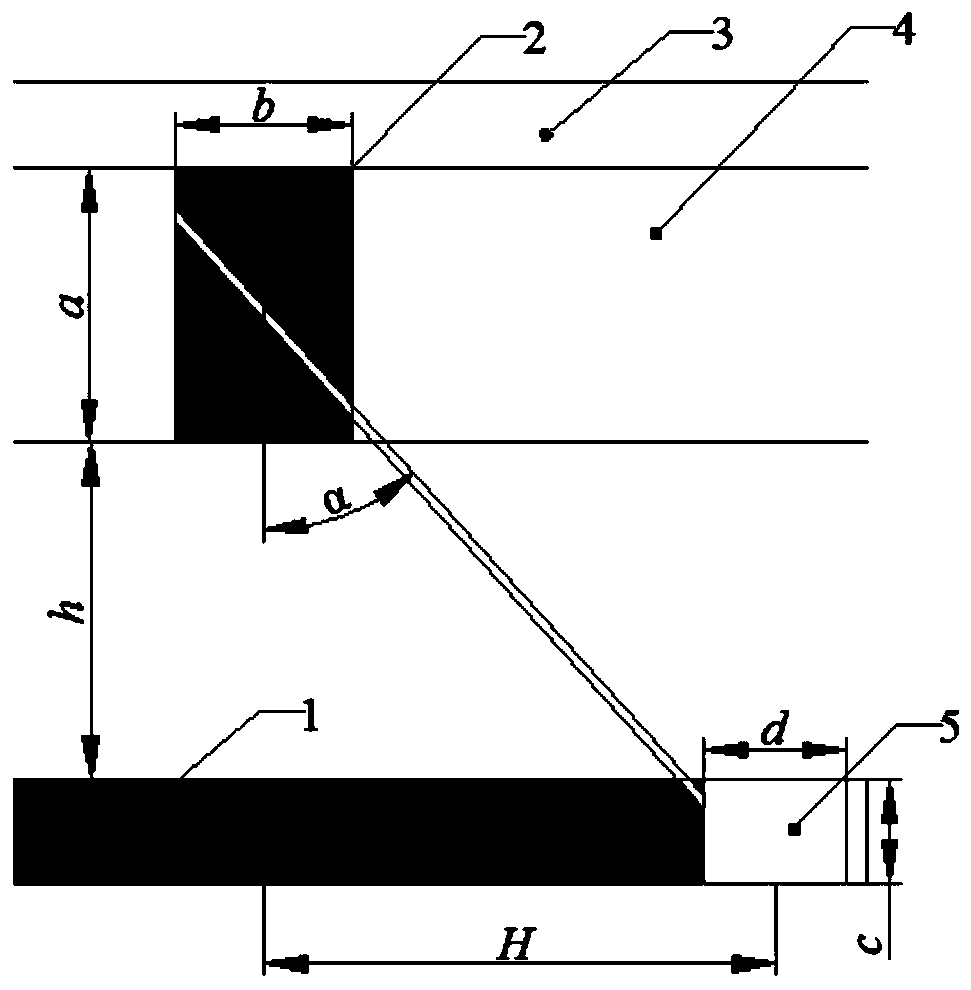

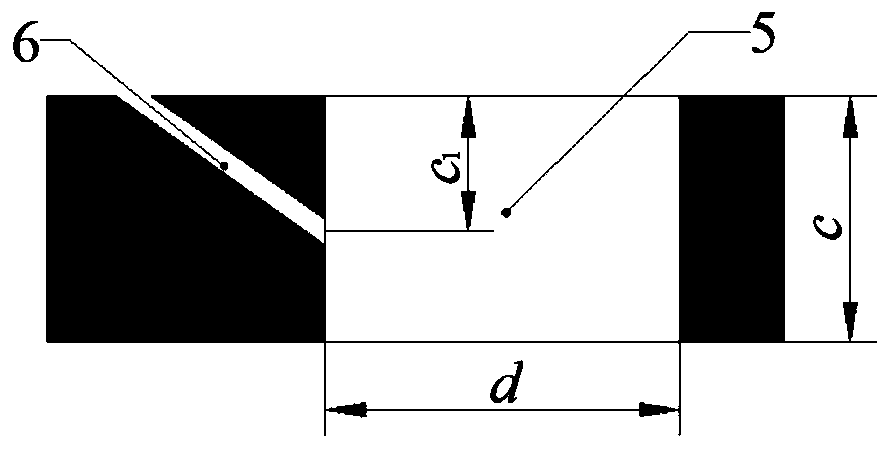

[0046] The height a and width b of the rectangular coal pillar 2 of a certain mine are 3m and 5m, respectively, and the height c and width d of the lower coal seam roadway 5 are 3m and 4.5m, respectively. The bottom of the remaining coal pillar 2 and the roof of the lower coal seam 1 The vertical distance h is 20m, and the horizontal distance H from the 2 centroid of the remaining coal pillar to the 5 centroid of the lower coal mining roadway is 15m.

[0047] Drilling core for the remaining coal pillar 2 in the upper coal seam. Considering that the height-to-diameter ratio has a greater impact on the failure mode of the remaining coal pillar 2, the core must be processed into a specimen with the same height-diameter ratio as the coal pillar before proceeding. Uniaxial compression test, from the experimental point of view, it is determined that the failure mode conforms to the shear failure mode; further the variable angle shear test is performed to measure the internal friction an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com