Micropower oxygen enrichment device

A micro-power, oxygen-enriched technology, applied in the direction of oxygen preparation, indirect carbon dioxide emission reduction, oxygen/ozone/oxide/hydroxide, etc., can solve the problem that the temperature can only reach below 200 degrees, and the waste treatment efficiency is greatly affected. Problems such as low calorific value of waste, to achieve the effect of improving waste pyrolysis efficiency, increasing oxygen content, and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. Obviously, the described embodiments are part of the present invention Embodiments, not all embodiments; based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work all belong to the protection scope of the present invention.

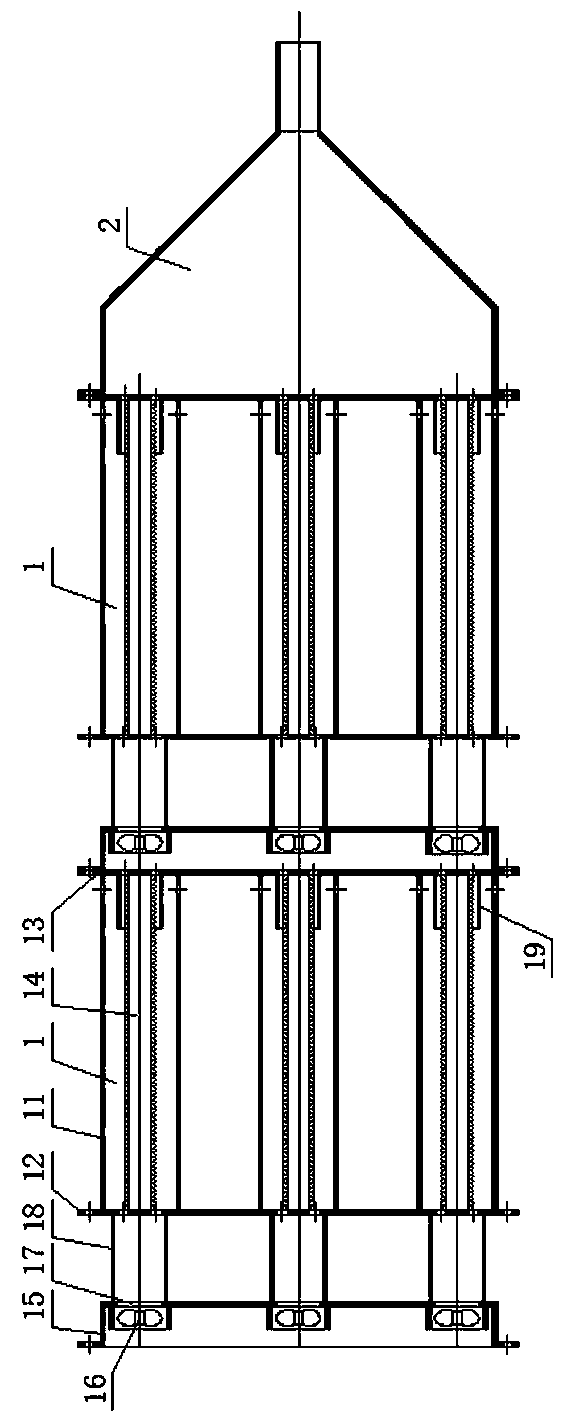

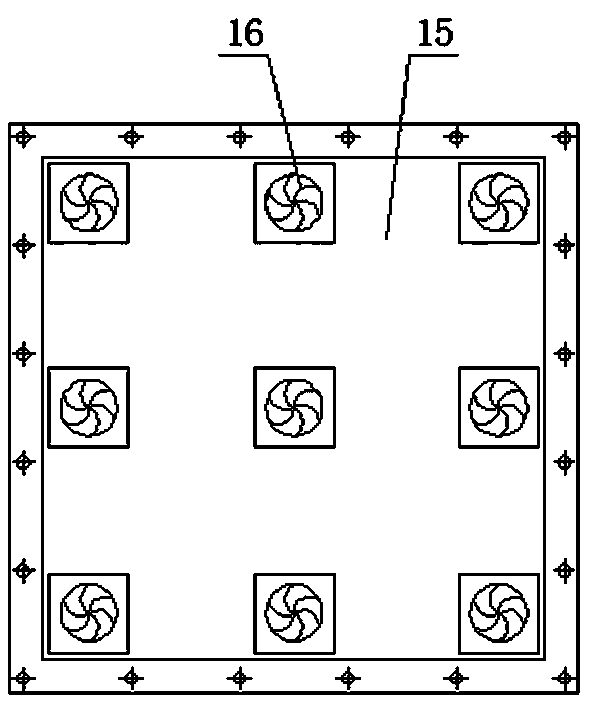

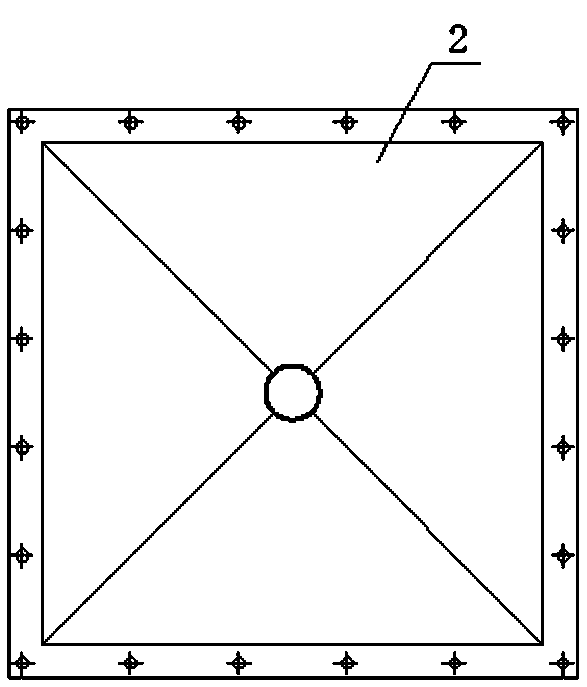

[0021] Such as Figure 1-3 As shown, the micro-power oxygen enrichment device of the present invention includes gas collection hoods 2 and a plurality of oxygen and nitrogen separation units 1 connected in series;

[0022] The oxygen-nitrogen separation unit includes an air duct 11, a front connecting plate 12, a rear connecting plate 13, a high-strength magnetic bar 14, a fixing groove 15, a fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com