Polymer molecular weight testing device and testing method

A testing device and molecular weight technology, which is applied in the field of measuring instruments, can solve the problems of cumbersome operation, limited measurement range, and high price, and achieve the effects of accurate and stable measurement results, simple structure, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific embodiments:

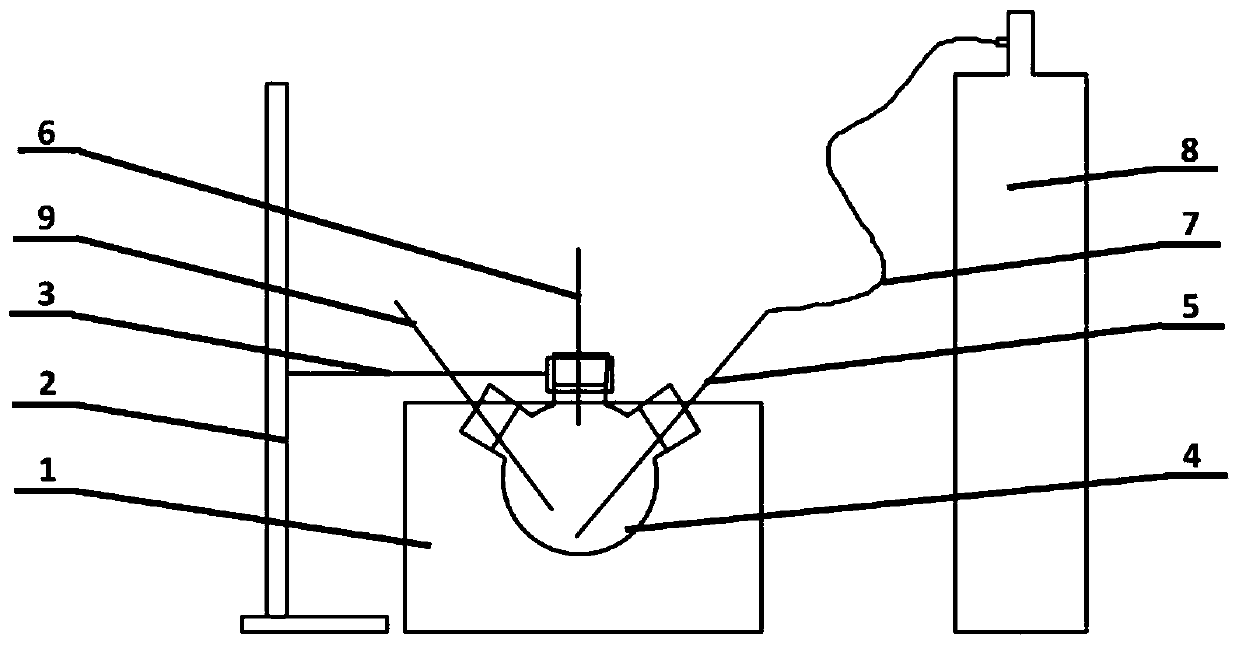

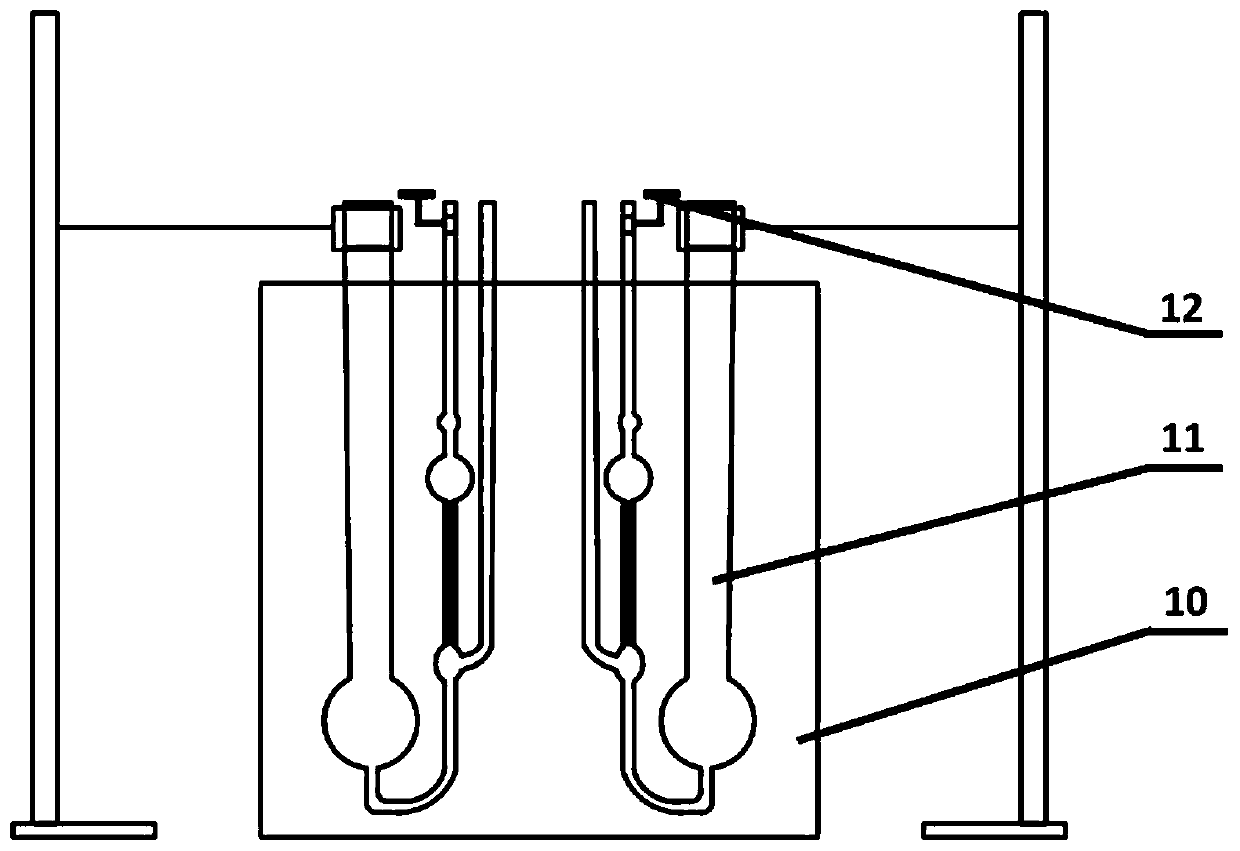

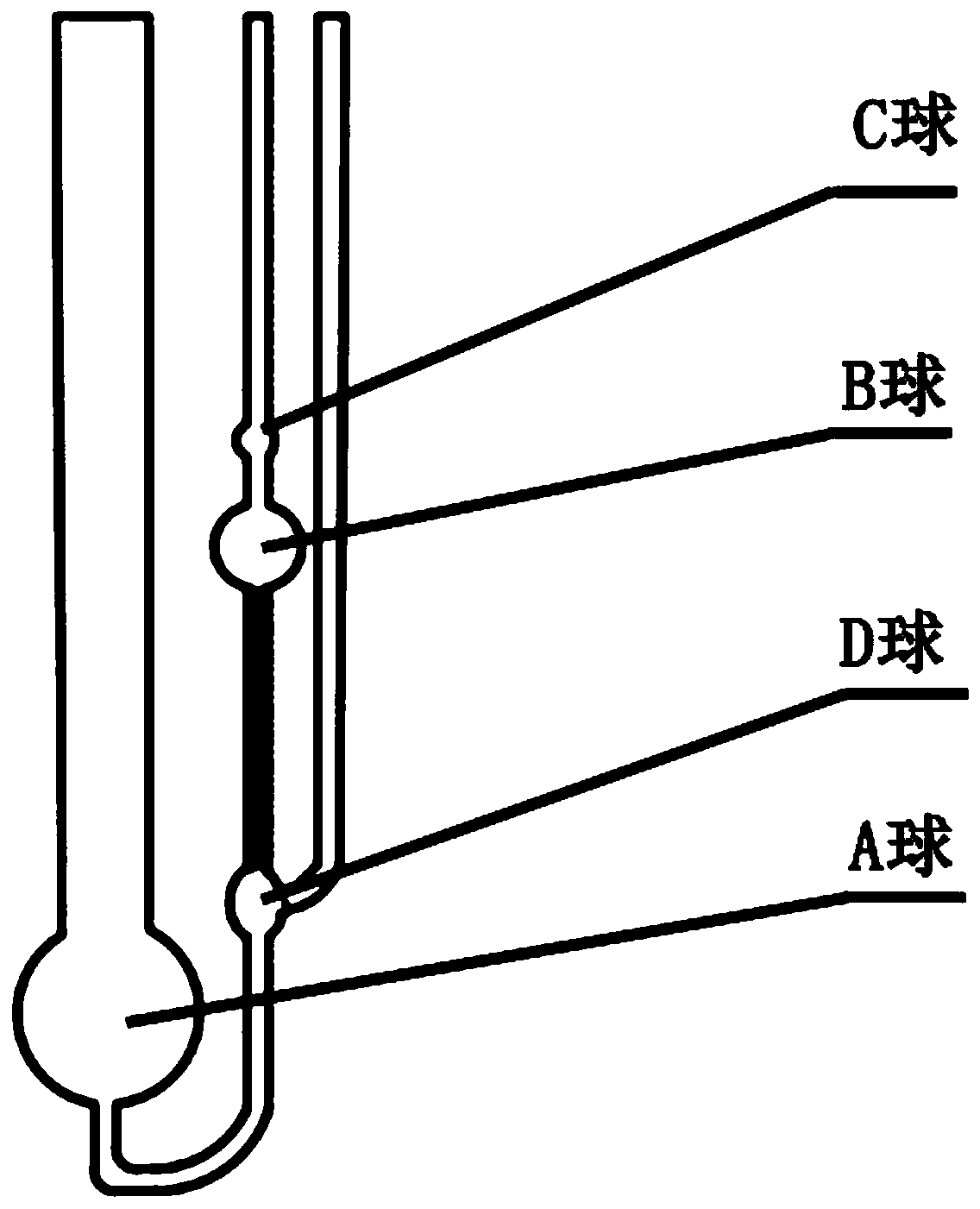

[0022] As shown in the drawings, the present invention is a polymer molecular weight testing device, which includes a heat-collecting thermostatic heating magnetic stirrer 1, an iron stand 2, a test tube clamp 3, a three-necked flask 4, an air inlet pipe 5, an air outlet pipe 6, and a rubber tube 7. Nitrogen bottle 8, thermometer 9, intelligent constant temperature bath 10, Ubbelohde viscometer 11, bubble level 12. The heat-collecting constant temperature heating magnetic stirrer 1, iron stand 2, test tube clamp 3, three-necked flask 4, air inlet pipe 5, air outlet pipe 6, rubber tube 7, nitrogen bottle 8, and thermometer 9 together form a dissolving mechanism. The three-necked flask 4 is placed in the thermal-collecting thermostatic heating magnetic stirrer 1, and an iron stand 2 is set on the side of the thermal-collecting thermost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com