Transformer substation full-time tracking thermal imaging temperature measurement monitoring system

A technology for monitoring systems and substations, applied in closed-circuit television systems, components of television systems, transmission systems, etc., can solve the problems of increasing the workload of operation and maintenance personnel, high prices, and small quantities, and reduce labor costs and equipment procurement cost, accurate and fast collection of information, and the effect of intelligent management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

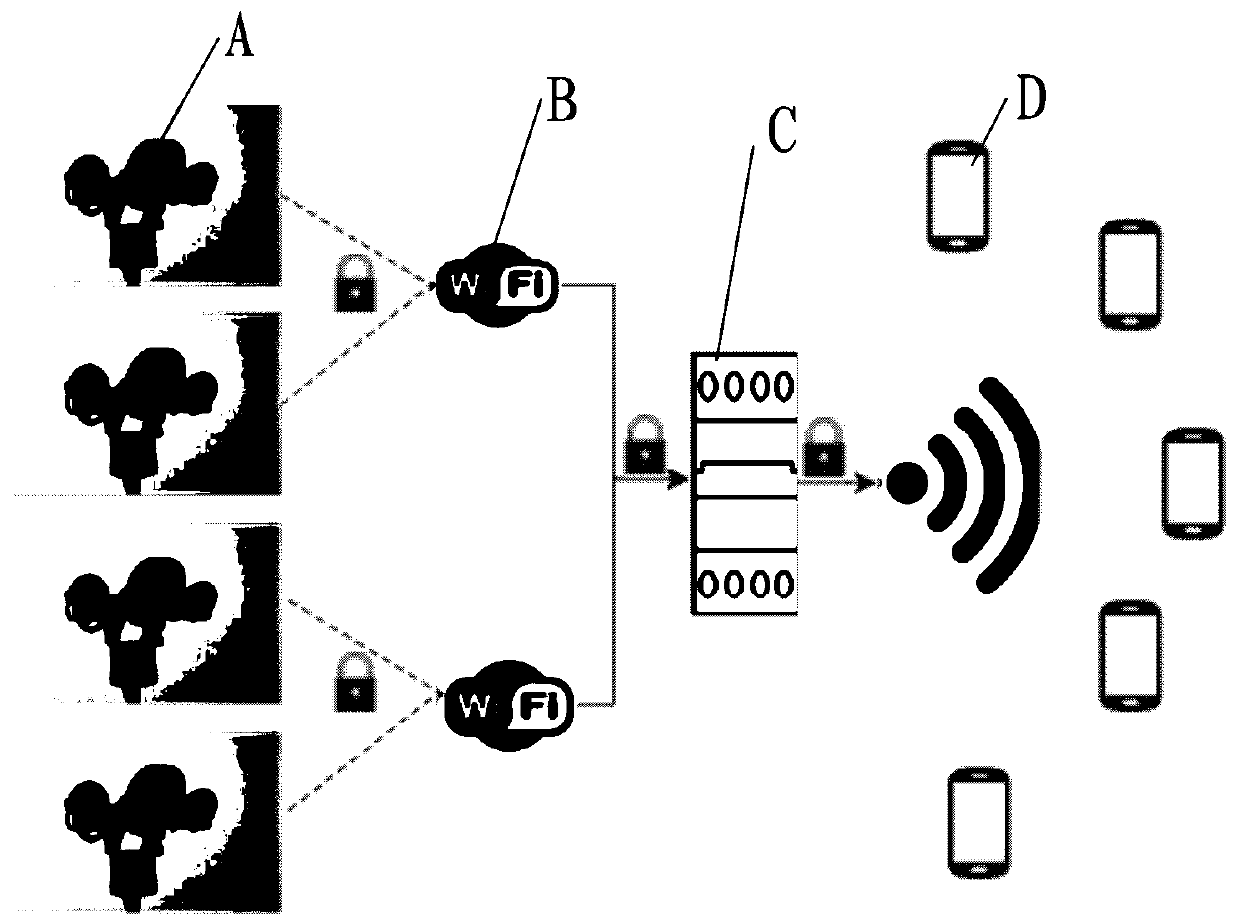

[0033] Example: see figure 1 , In the figure, A-digital PTZ, B-embedded controller, C-server, D-backstage terminal.

[0034] Substation full-time tracking thermal imaging temperature measurement monitoring system, image information acquisition subsystem, equipment temperature data analysis and processing subsystem, data output subsystem, image information acquisition subsystem collects substation image information, and then through the equipment temperature data analysis and processing subsystem The system processes the collected image information and sends it wirelessly to the data output subsystem, and finally transmits the processed information to the background terminal for display through the data output subsystem, specifically:

[0035] The image information acquisition subsystem includes a digital cloud platform and an infrared camera and a visible light camera arranged on the digital cloud platform, and the digital cloud platform, the infrared camera and the visible li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com