Light-shielding composite film, preparation method thereof and application thereof

A composite film and shading technology, which is applied in the field of shading materials, can solve the problems that cannot meet the simple and light fashion development trend of decorative textiles, affect the appearance and shading of roller blinds, and deteriorate the drape performance and air permeability, etc. Application prospect and market prospect, easy industrial production, good shading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Preparation of light-shielding composite film

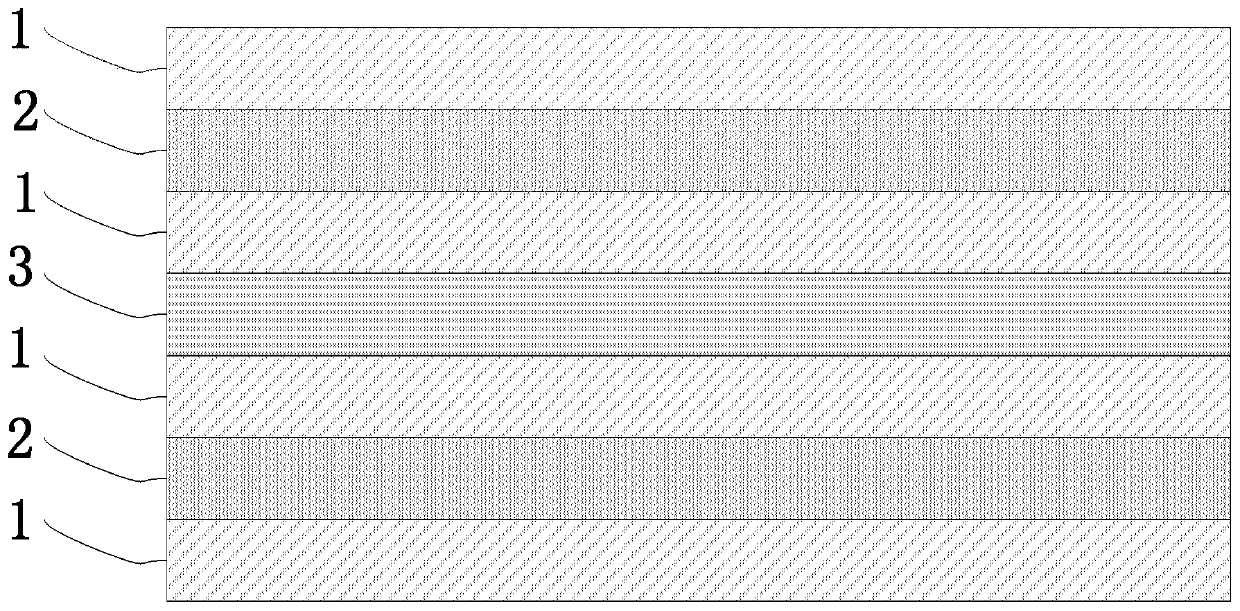

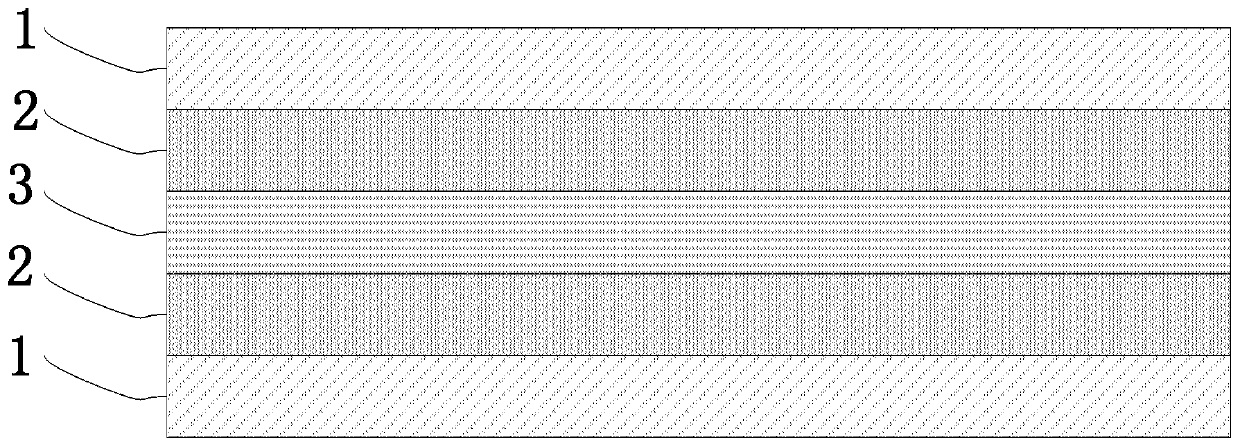

[0044] like figure 1 As shown, the embodiment of the present invention provides a light-shielding composite film, which has a multilayer structure of light-reflecting layer 1-light-absorbing layer 2-light-reflecting layer 1-non-woven fabric 3-light-reflecting layer 1-light-absorbing layer 2-light-reflecting layer 1 ( The reflective layer 1 on the outside can contain pigments to present the required color), the present invention adopts the processing method of extruding into a film, and realizes the reflective layer-light-absorbing layer-reflective layer-non-woven fabric-reflective layer- Light-absorbing layer-light-reflecting layer seven-in-one light-shielding polymer film forming technology, the structural characteristics of the seven-layer polymer film, compared with the three-layer film structure of light-reflecting layer-light-absorbing layer-light-reflecting layer, has a higher shading effect At the same time, it als...

Embodiment 1

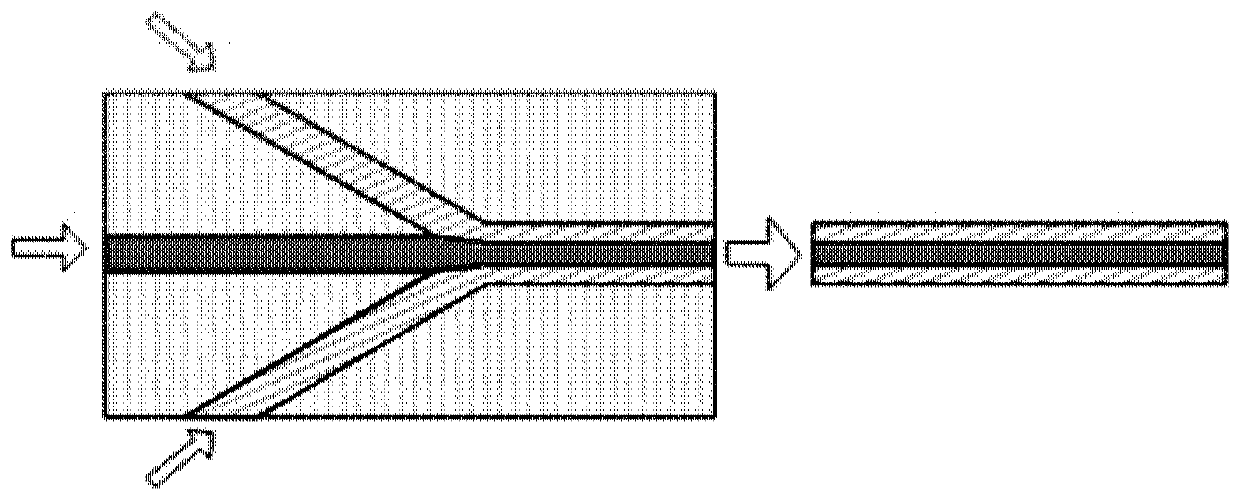

[0056] Mix the dried PE resin raw material with reflective particles and light-absorbing particles respectively; the mixing weight ratio of PE resin and light-reflecting particles is 64:35, and the mixing weight ratio of PE resin and light-absorbing particles is 69:30, and then add the dispersant EHBA1. 0 parts On the basis of thorough mixing, add the mixture into the three-screw extruder respectively to ensure that the mixed resin of reflective particles, mixed resin of light-absorbing particles and mixed resin of reflective particles are respectively directed to the upper, middle and lower layers of the extrusion die, such as image 3 shown.

[0057] The temperature control of the three-screw extruder is as follows: the temperature of the feeding heating zone is 30°C higher than the melting point of the resin, and the temperature of the three-input co-extrusion T-die is controlled at 25°C higher than the melting point.

[0058] The film extruded by the three-input co-extrusi...

Embodiment 2

[0062] Mix the dried PE resin raw material with reflective particles and light-absorbing particles respectively; the mixing weight ratio of PE resin and light-reflecting particles is 70:29, and the mixing weight ratio of PE resin and light-absorbing particles is 64:35, and then add the dispersant EHBA1. 0 part, on the basis of thorough mixing, add the mixture into the twin-screw extruder respectively, and ensure that the mixed resin of the reflective particles and the resin of the light-absorbing particles are respectively directed to the upper and lower layers of the extrusion film mouth, such as Figure 4 shown.

[0063] The temperature of the twin-screw extruder is controlled so that the temperature of the feed heating zone is 30°C higher than the melting point of the resin, and the temperature of the two-input co-extrusion and one die is controlled at 25°C higher than the melting point.

[0064] The two-input coextruded one-die extruded film was stretched to a thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com