Air vehicle adopting large-aspect-ratio double-fuselage flying wing layout

A technology with large aspect ratio and aircraft, applied in the field of aircraft, can solve the problems of small aspect ratio and low aerodynamic efficiency, and achieve the effect of small flight resistance, high aerodynamic efficiency and high flight lift-to-drag ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

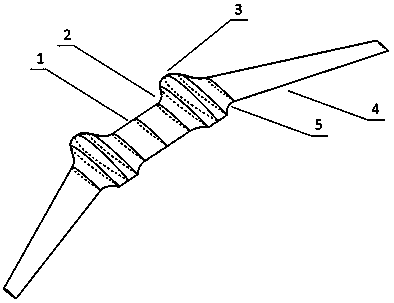

[0024] Present embodiment adopts two symmetrically arranged fuselages 3, from the perspective of plane projection, as figure 1 As shown, the two fuselages 3 are distributed symmetrically and arranged parallel to each other on the same horizontal plane. The straight wing 1 is used to connect two fuselages 3, the two ends of the straight wing 1 are respectively connected to a fuselage 3 through an inner wing-body fusion section 2, and the outer sides of each fuselage 3 are fused through the outer wing body Segment 5 connects an outboard wing 4 .

[0025] Compared with the existing single fuselage layout, the fuselage layout implemented in this implementation adopts twin fuselages and straight wings, which increases the internal space of the two fuselages, so the overall structural layout is more convenient. The overall structural efficiency is higher than the existing single fuselage layout.

[0026] For this embodiment, in order to realize the convenience of processing and m...

Embodiment 2

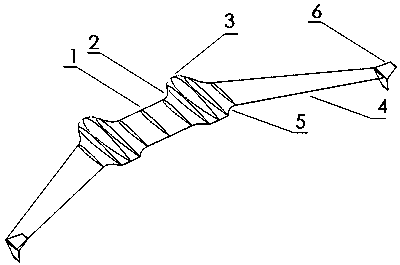

[0034] Such as figure 2 As shown, on the basis of Embodiment 1, a wingtip vertical tail 6 is added to the tip of the outer wing 4, the purpose of which is to increase the heading stability.

[0035] For the layout of the engine in the above two embodiments, the following two different arrangements of built-in and external can be adopted:

[0036] Built-in engine: An engine is respectively arranged in the two fuselages, and the engine is used to realize push-back propulsion.

[0037] External engine:

[0038] The first type is that the external suspension engines on the two fuselages can be arranged above or below the fuselage, and the engines can be used to realize push-back propulsion.

[0039] In the second type, the engine is suspended at the center of the straight wing, which can be above or below the straight wing, and the engine is no longer arranged on the fuselage.

[0040] Above-mentioned engine can adopt jet engine, also can adopt conventional piston or turboshaf...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap