Automatic zinc ingot stack line getting-off and truck loading control system

A technology of automatic off-line and control system, applied in motor vehicles, conveyor control devices, transportation and packaging, etc., can solve problems such as collapse of zinc ingots, loose stacking, production accidents, etc., and achieve the effect of solving collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

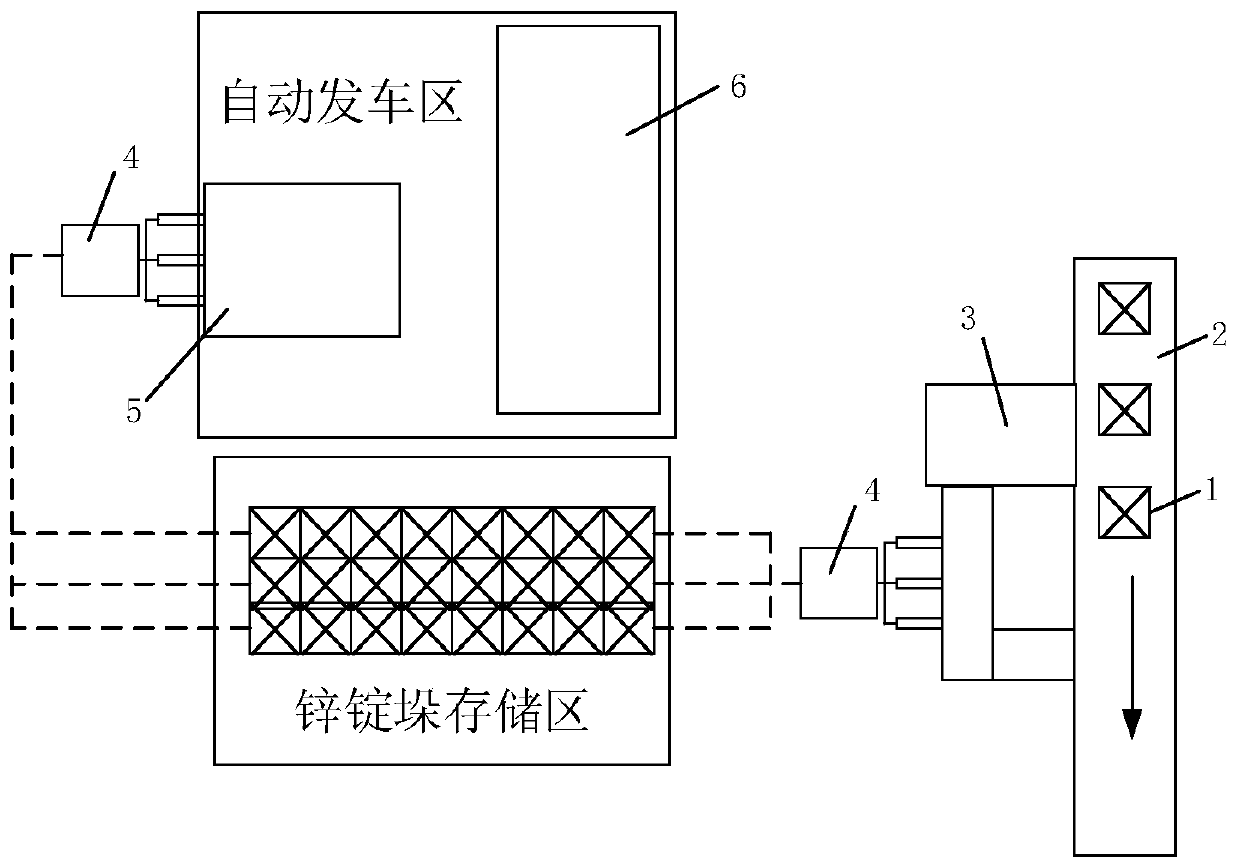

[0033] figure 1 It is a schematic distribution diagram of the zinc ingot stack automatic off-line loading control system of the present invention.

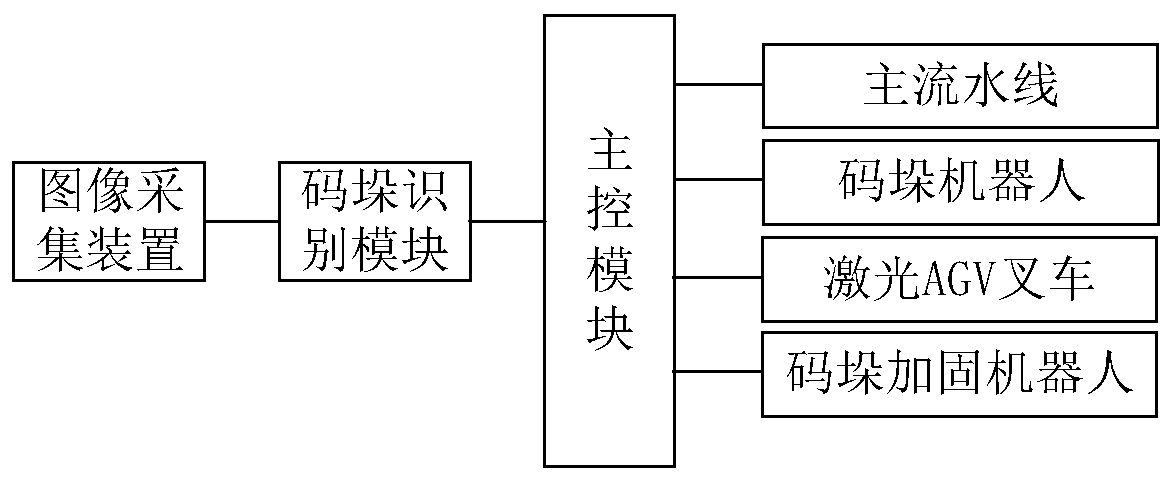

[0034] figure 2 It is the control principle diagram of the zinc ingot stack automatic off-line loading control system of the present invention.

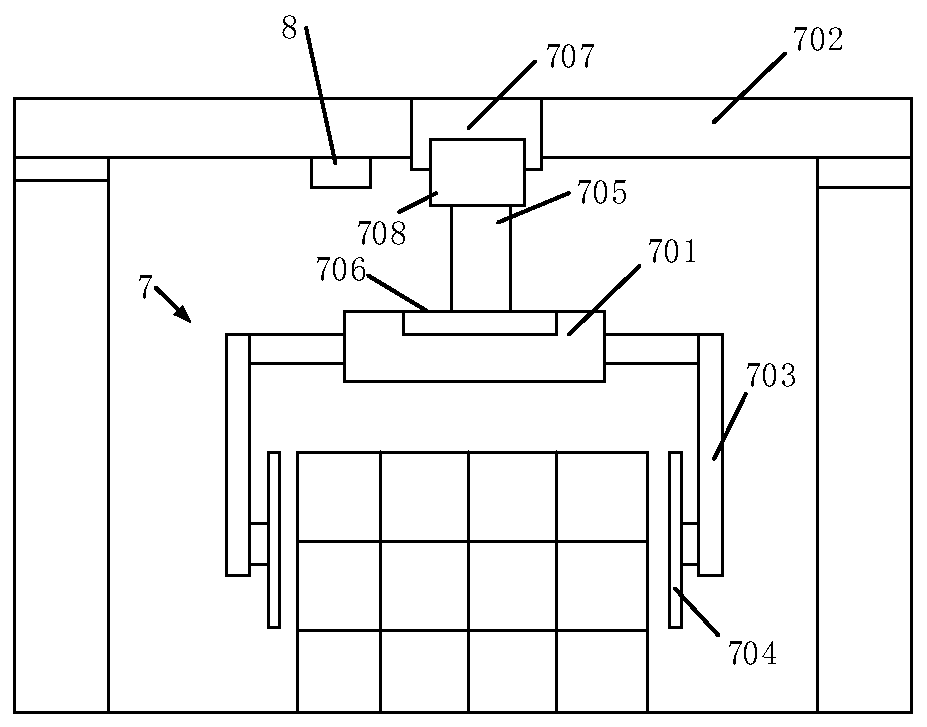

[0035] Such as figure 1 with figure 2 As shown, this embodiment provides a zinc ingot stack automatic off-line loading control system, including: a main streamline 2 for conveying zinc ingots, and a stacker for grabbing zinc ingots from the main streamline 2 for stacking A robot 3, and a laser AGV forklift 4 that transports the zinc ingot stack to the zinc ingot stack storage area; an image acquisition device 8 is arranged on the upper part of the zinc ingot stack storage area to take a bird's-eye view image of the zinc ingot stack; The recognition module receives the top-view image sent by the image acquisition device 8, and judges the stacking state of the zinc ingot stacks. If t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com