A kind of preparation method of parallel Gan-based LED chip

A LED chip and parallel technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low production efficiency, inconsistent height, poor uniformity, etc., and achieve low cost, stable product performance, and high packaging efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

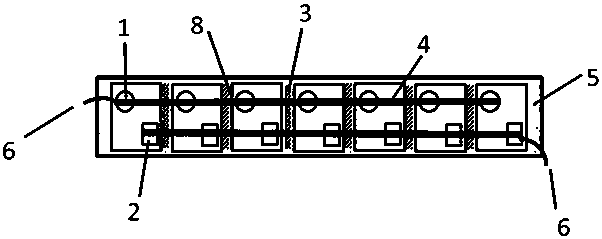

[0032] The method for preparing parallel GaN-based LED chips of the present invention comprises the following steps:

[0033] (1) Preparation of epitaxial wafers

[0034] An epitaxial layer is grown on the sapphire substrate 5 to form an epitaxial wafer. The epitaxial layers are GaN layer, N-type GaN layer, quantum well active region and P-type GaN layer from bottom to top. In order to effectively activate the activity of doping impurities in the P-type GaN layer, a layer with a thickness of The ITO transparent conductive layer.

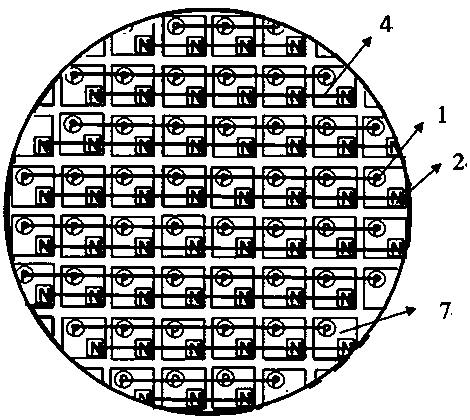

[0035] (2) Half-cutting the epitaxial wafer

[0036] The epitaxial wafer is cut vertically and horizontally according to the size of a single chip unit 7 with a laser scribing machine, with a cutting depth of 6-7um, to the substrate 5, so that isolation grooves 8 are formed between adjacent chip units 7.

[0037] (3) Fill the isolation groove to ensure the insulation between chip units

[0038] On the surface of the epitaxial wafer, polyimide 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com