PVA (Polyvinyl Alcohol) sodium alginate dual-network cold-resistant conductive hydrogel and preparation method thereof

A conductive hydrogel and sodium alginate technology, applied in the field of hydrogel preparation, can solve the problems of poor cold resistance of self-healing hydrogel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

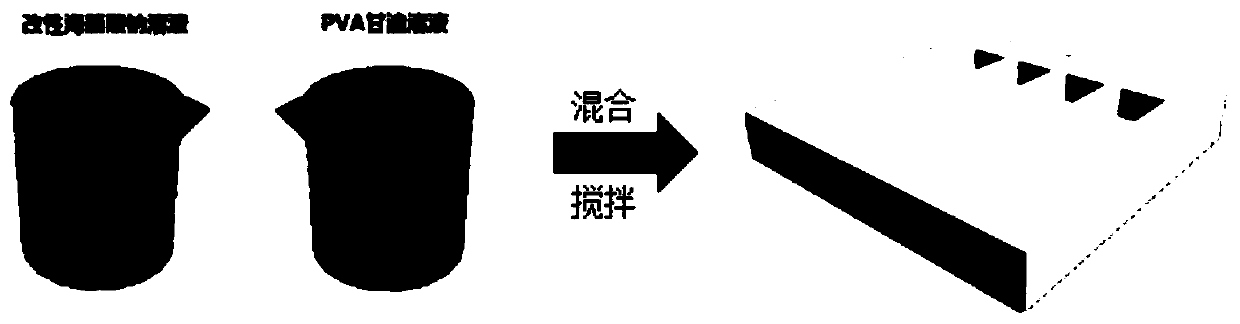

[0022] The present invention firstly provides a preparation method of PVA sodium alginate double-network cold-resistant conductive hydrogel, the reaction process and principle schematic diagram are as follows figure 1 As shown, the method includes:

[0023] Step 1: Dissolve sodium alginate in deionized water, add EDC·HCl and m-aminophenylboronic acid to react, the reaction temperature is preferably room temperature, and the reaction time is preferably 20-24h, and the product is dialyzed, and the dialysis The time is preferably 5-7 days, then lyophilized, and then the lyophilized product is dissolved in deionized water and stirred, the stirring rate is preferably 800-1000r / min, and the stirring time is preferably 3-5h to obtain the first solution ;

[0024] The mass ratio of the sodium alginate, EDC·HCl and m-aminophenylboronic acid is preferably (1-1.5): (0.96-1.0): 0.33, more preferably 1: 0.96: 0.33; the lyophilized The mass g of the product: the volume mL of deionized wat...

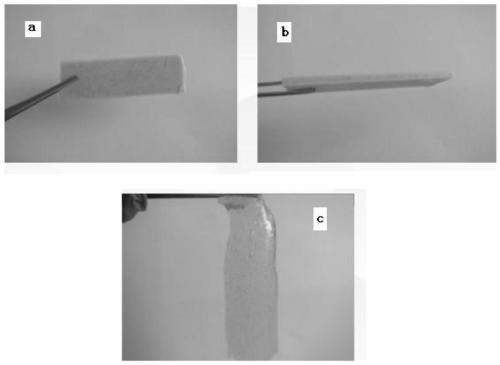

Embodiment 1

[0032] Step 1: Take 2.5g (0.125mol) of sodium alginate and dissolve it in deionized water, add 2.4g (12.5mol) of EDC HCl and 0.825g (6.25mol) of m-aminophenylboronic acid, stir at room temperature for 24h, and dialyze the product. The size of the bag is 14000, dialysis for 7 days, change the water every 24 hours, put the dialysate into a freeze dryer and freeze-dry to obtain modified sodium alginate, weigh 0.5g of modified sodium alginate and dissolve it in 10ml of deionized water , magnetically stirred at a speed of 900r / min at room temperature for 4h until completely dissolved to obtain the first solution;

[0033] Step 2: Add 10ml of glycerin to 10ml of deionized water at room temperature and continue to stir with a magnetic stirrer for 10min until the two phases are completely miscible. Dissolve 2g of PVA and polyaniline 0.04 in 20ml of deionized water and glycerin mixture with a volume ratio of 1:1 , under the condition of 90°C, magnetically stir at a speed of 1000r / min f...

Embodiment 2

[0040] Step 1: Take 2.5g (0.125mol) of sodium alginate and dissolve it in deionized water, add 2.4g (12.5mol) of EDC HCl and 0.825g (6.25mol) of m-aminophenylboronic acid, stir at room temperature for 24h, and dialyze the product. The size of the bag is 14000, dialysis for 7 days, change the water every 24 hours, put the dialysate into a freeze dryer and freeze-dry to obtain modified sodium alginate, weigh 0.5g of modified sodium alginate and dissolve it in 10ml of deionized water , magnetically stirred at a speed of 900r / min at room temperature for 4h until completely dissolved to obtain the first solution;

[0041] Step 2: Add 10ml of glycerin to 10ml of deionized water at room temperature and continue to stir with a magnetic stirrer for 10min until the two phases are completely miscible. Dissolve 1.5g of PVA and polyaniline 0.05 in 20ml of deionized water and glycerin mixture with a volume ratio of 1:1 At 95°C, stir magnetically at a speed of 1000r / min for 2h until the PVA ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com