Quantum dot cladding method and prepared shell-clad quantum dot

A technology of quantum dots and shell layers, applied in the field of nanomaterial preparation, can solve the problems such as the red shift of the fluorescence emission wavelength of quantum dots and the difficulty in controlling the wavelength of quantum dots, and achieve the effect of high fluorescence quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0042] According to a preferred embodiment of the present application, the method for quantum dot cladding comprises steps:

[0043] S2', at a preset low temperature, adding the first ion precursor to the mixed solution containing quantum dots to form a mixed solution containing quantum dots and the first ion precursor;

[0044] S3', adding the second ion precursor to the mixed liquid containing the quantum dot and the first ion precursor in multiple times, the first ion precursor and the second ion precursor react in multiple times and form a shell on the quantum dot .

[0045] In a preferred embodiment, the method for quantum dot cladding comprises steps:

[0046] S2', at a preset low temperature, adding the first ion precursor to the mixed solution containing quantum dots to form a mixed solution containing quantum dots and the first ion precursor;

[0047] S3', adding an equimolar amount of the second ion precursor to the mixed solution containing the quantum dot and the...

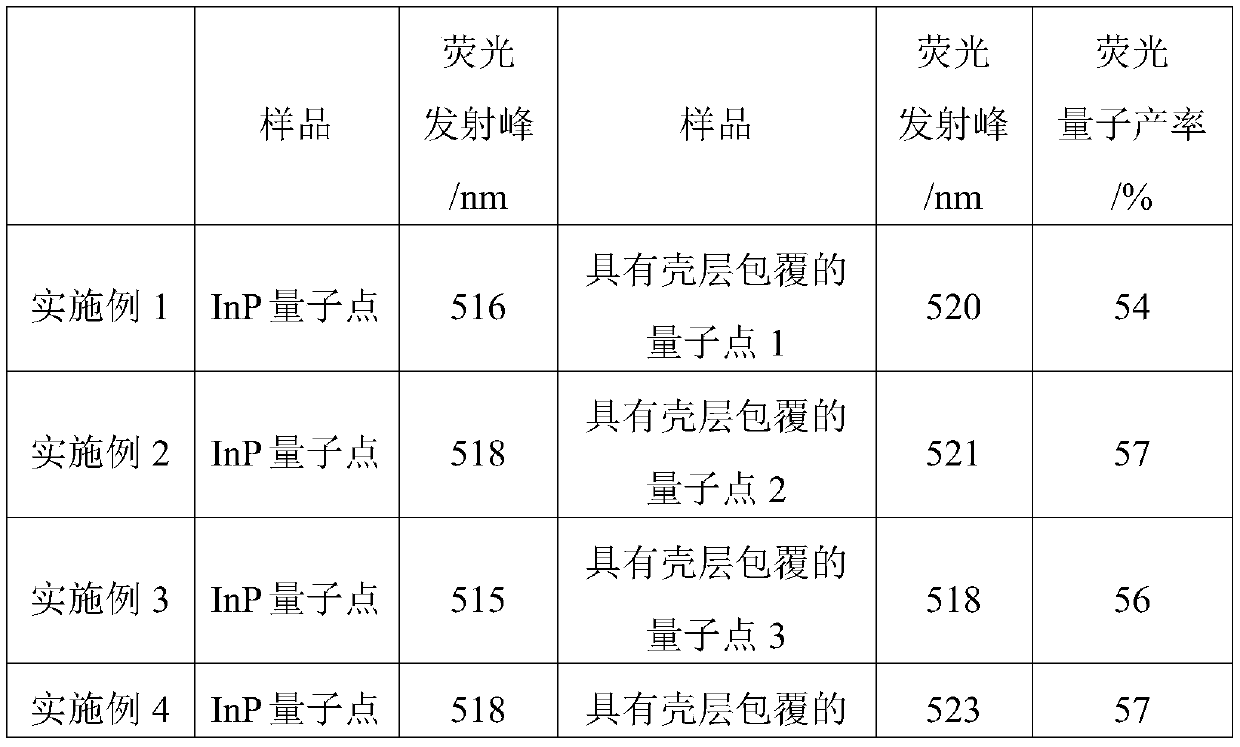

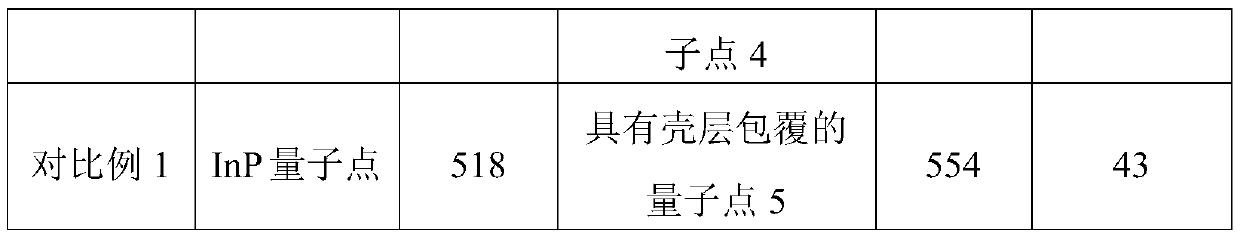

Embodiment 1

[0067] Preparation of quantum dot 1:

[0068] S1. Obtain a mixed solution including InP quantum dots:

[0069] S1-1. Under an inert gas atmosphere, make 1mmol In(OAc) 3 , 1mmol Zn(OAc) 2 , 3mmol oleic acid, 20mL octadecene, and 0.8mmol tris(trimethylsilyl)phosphine were mixed, heated and reacted to prepare InP quantum dots;

[0070] S1-2. Precipitate and purify the above-mentioned InP quantum dots using known methods, and disperse the purified InP quantum dots in 10 mL of octadecene solution to obtain a mixed solution including InP quantum dots;

[0071] S2, coating ZnS shell for InP quantum dots:

[0072] S2-1. At 200°C, add 24 mmol of zinc stearate in octadecene solution to the mixed solution including InP quantum dots, and react for 60 minutes;

[0073] S2-2. Add 8 mmol sulfur tri-n-octylphosphine solution to the reaction system of S2-1, and react for 30 minutes;

[0074] S2-3. Repeating step S2-2 for a total of 3 times to coat the InP quantum dots with a ZnS shell lay...

Embodiment 2

[0076] Preparation of quantum dot 2:

[0077] S1. Obtain a mixed solution including InP quantum dots:

[0078] Under an inert gas atmosphere, make 1mmol In(OAc) 3 , 1mmol Zn(OAc) 2 , 3mmol oleic acid, 20mL octadecene, and 0.8mmol tris(trimethylsilyl)phosphine were mixed, heated and reacted to obtain a mixed solution including InP quantum dots;

[0079] S2. Coating ZnSe / ZnS shells for InP quantum dots:

[0080] S2-1. At 180°C, add 24 mmol of zinc stearate in octadecene solution to the mixed solution including InP quantum dots, and react for 60 minutes;

[0081] S2-2. Add 4 mmol of selenium tri-n-octylphosphine solution to the reaction system of S2-1, react for 60 minutes, then add 4 mmol of selenium tri-n-octylphosphine solution, and react for 60 minutes to coat the ZnSe subshell for InP quantum dots layer;

[0082] S2-3. Add 8 mmol of sulfur tri-n-octylphosphine solution to the reaction system of S2-2, react for 60 minutes, then add 8 mmol of sulfur tri-n-octylphosphine s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com