Large pulverized coal boiler ultralow-load coal economizer switching bypass system

A technology for pulverized coal boilers and economizers, applied in feed water heaters, preheating, steam generation, etc., to achieve the effects of increasing inlet smoke temperature, enhancing stable combustion capabilities, and expanding the available load range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

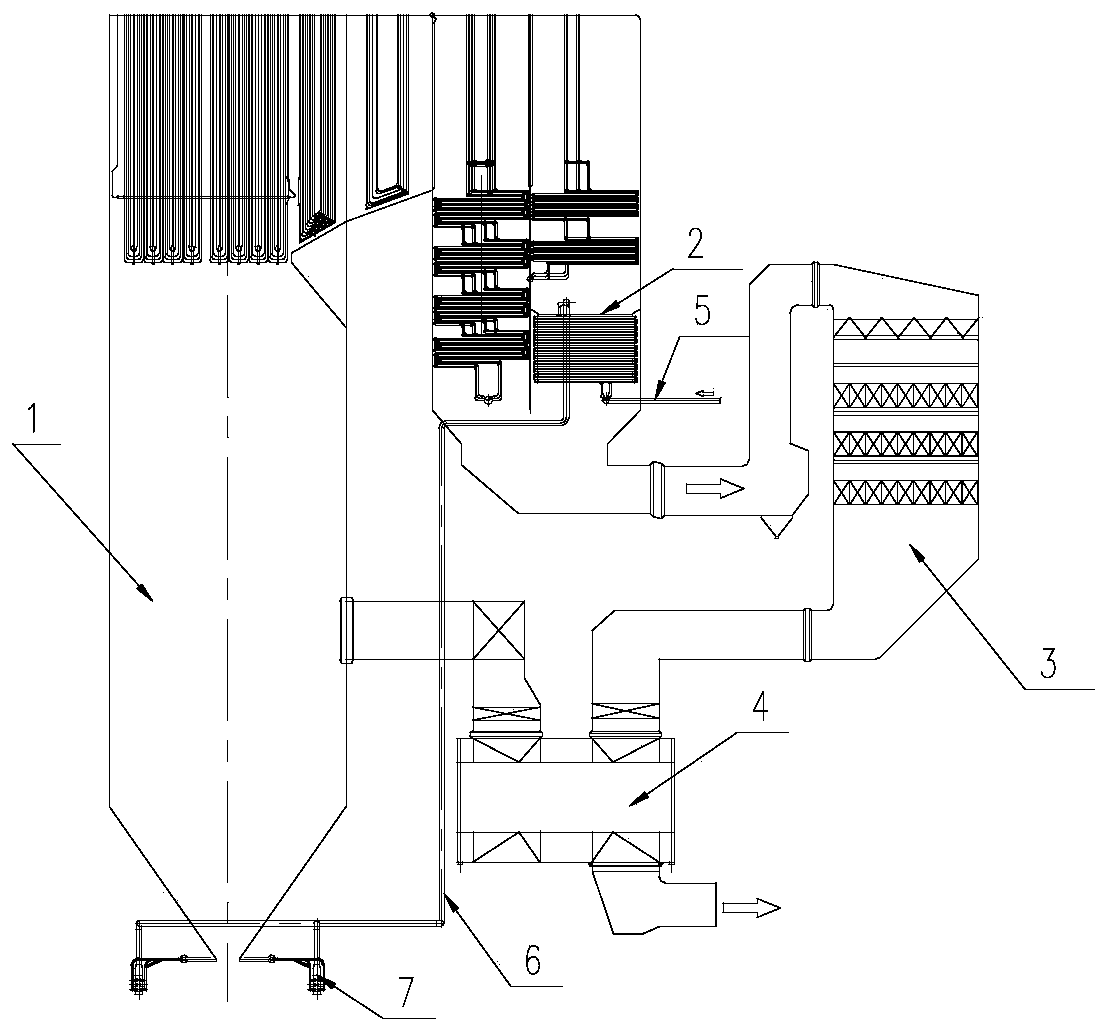

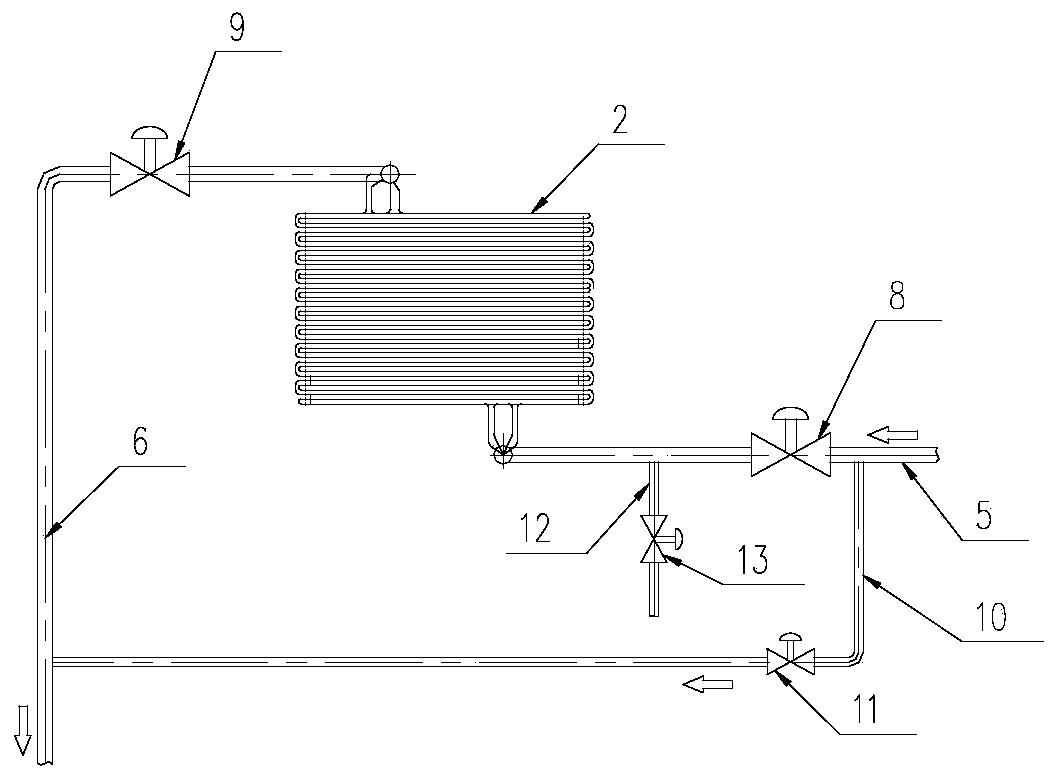

[0015] like figure 1 and figure 2 As shown, a large-scale pulverized coal boiler ultra-low load economizer switching bypass system involved in this embodiment includes a boiler body 1, an economizer 2, a denitrification device SCR3, an air preheater 4, and a boiler water supply pipe 5 , the flue gas outlet of the economizer 2 installed on the boiler body 1 is connected to the flue gas inlet of the air preheater 4 through the denitrification device SCR3, and the heated air outlet of the air preheater 4 is connected to the inside of the boiler body 1. The water inlet of the heating surface of the economizer 2 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com