A quasi-static full-field deformation measurement device and method for a slender member

A technology of slender components and measurement methods, applied in the direction of measuring devices, using optical devices, and using stable tension/pressure to test the strength of materials, etc., can solve the problems of quasi-static full-range deformation measurement of slender components and effective resolution in the width direction Reduce the problem of cumbersome image acquisition steps, etc., to achieve the effect of simple structure, improved measurement efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

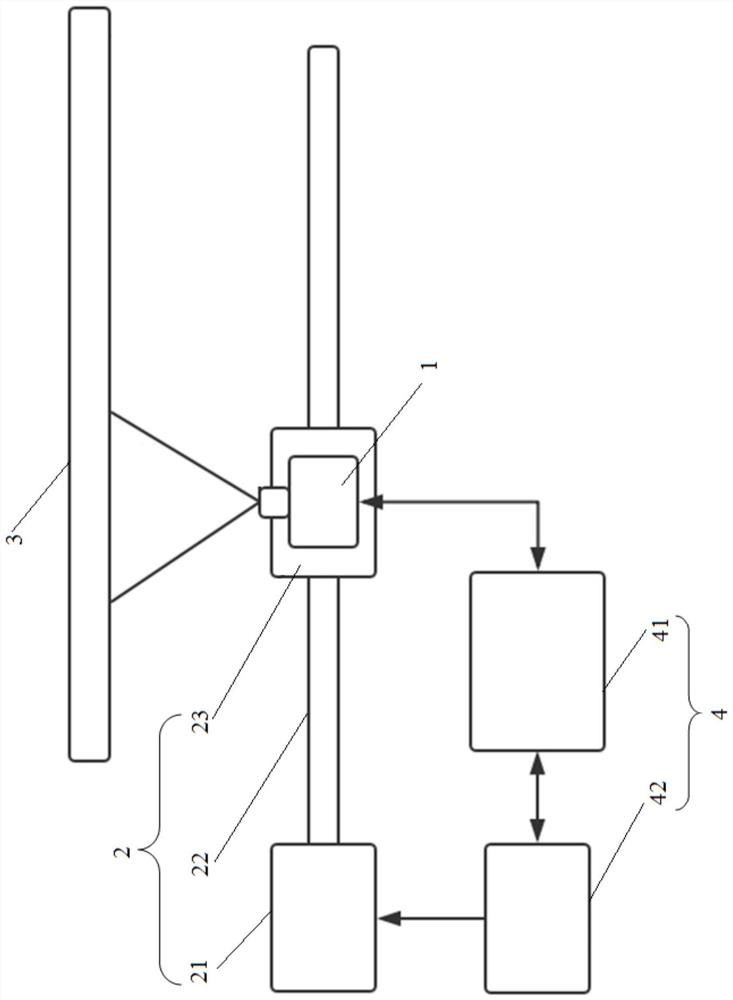

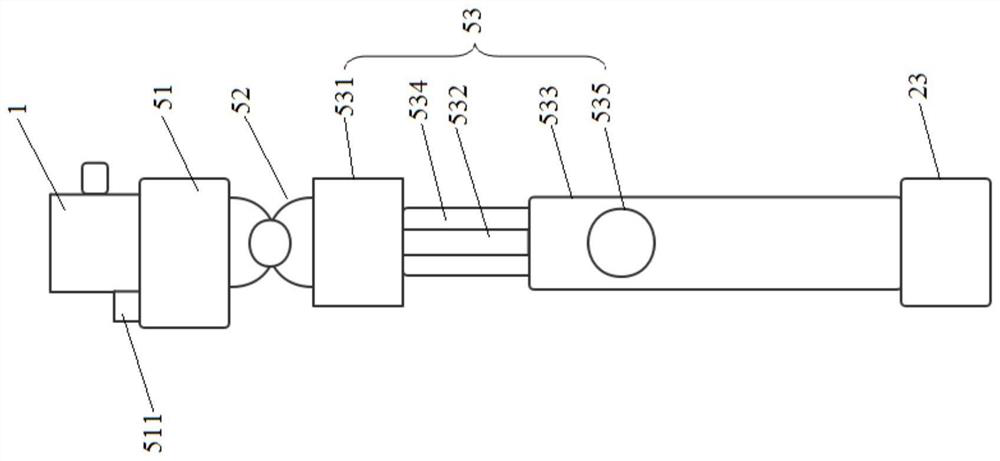

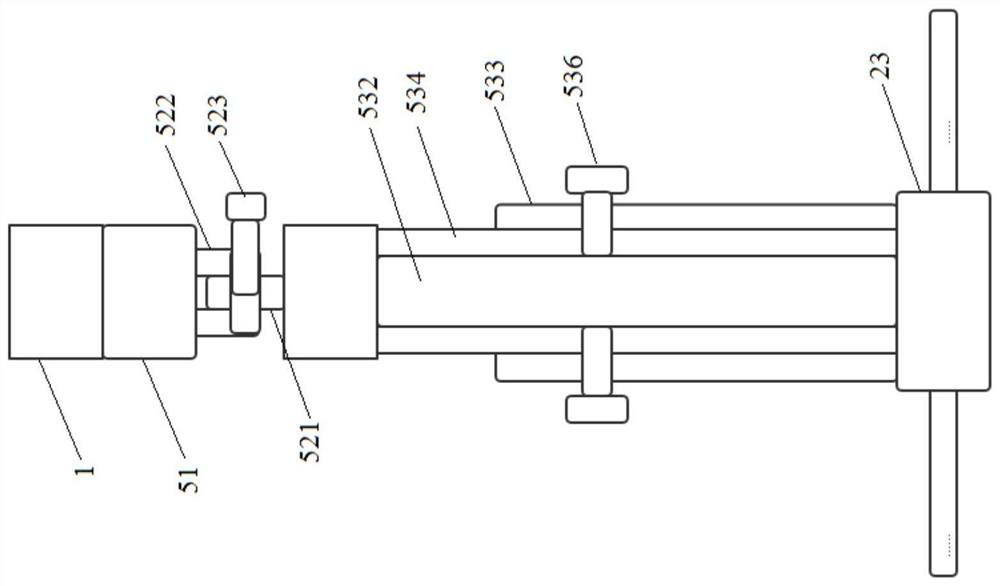

[0052] According to a preferred embodiment of the present invention, the camera mechanism 1 is a single industrial camera, which is fixedly connected with the driving mechanism 2 .

[0053] In a further preferred embodiment, the resolution of the camera mechanism 1 is 1280×1024.

[0054] Preferably, the industrial camera is preferably a MV-130UM series industrial camera made by Vision Intelligent, and its lens is preferably a Pentax TV LENS 16mm 1:1.4 industrial lens.

[0055] According to a preferred embodiment of the present invention, the drive mechanism 2 includes a drive motor 21 and a drive track 22 connected to each other, a slide table 23 is arranged on the drive track 22,

[0056] The camera mechanism 1 is fixedly connected to the slide table 23 .

[0057] In a further preferred embodiment, the driving track 22 is a lead screw, preferably a ball screw, which rotates under the drive of the drive motor to drive the slide table to move horizontally.

[0058] Preferably...

Embodiment 1

[0176] The selected elongated member is: a metal plate with a hole in the center, the length is 1m, the width is 5cm, and the height is 5cm.

[0177] The quasi-static full-field deformation measurement device for slender members is adopted, and the structure is as follows Figure 1~4As shown, wherein, the camera mechanism is a MV-130UM series industrial camera made by Weishizhi, and its lens is a Pentax TV LENS 16mm 1:1.4 industrial lens; the slide table is a single-axis slide table, which is controlled by a Siemens S7-200PLC controller .

[0178] Follow the steps below to measure:

[0179] Step 1: Obtain a panoramic image of the metal plate before it deforms.

[0180] Step 1-1: After the surface of the metal plate is polished, spray it flat with white paint as the bottom surface, and then spray black paint on the surface at a long distance to obtain the speckle size as 5 pixels.

[0181] Step 1-2, use the industrial camera to take the first image of the metal plate, after ...

Embodiment 2

[0191] For a point of x=25mm, y=150mm in the image stitched before deformation (the reference strain value obtained by ANSYS finite element analysis software is 9.528×10 -4 pixel), by changing different thresholds of gray-scale change density, the relative error of strain value and finite element parameter strain value and the statistical analysis results of the time to reach the threshold are obtained, as shown in Table 1:

[0192] Table 1

[0193]

[0194]

[0195] It can be seen from Table 1 that the larger the threshold value of the gray change density is set, the smaller the relative error is, and the higher the accuracy is, but at the same time, the longer the calculation time is, the lower the efficiency is; especially, when the threshold value is greater than 1.6, the accuracy does not increase much At the same time, the calculation time is significantly increased and the efficiency is reduced, so the threshold is preferably set to 1.6 in the present invention. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com