Display substrate, manufacturing method thereof, and display device

A technology of a display substrate and a manufacturing method, which is applied to semiconductor devices, electrical components, circuits, etc., can solve problems such as abnormal display of an anode graphic display device, and achieve the effects of ensuring production yield, ensuring yield, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

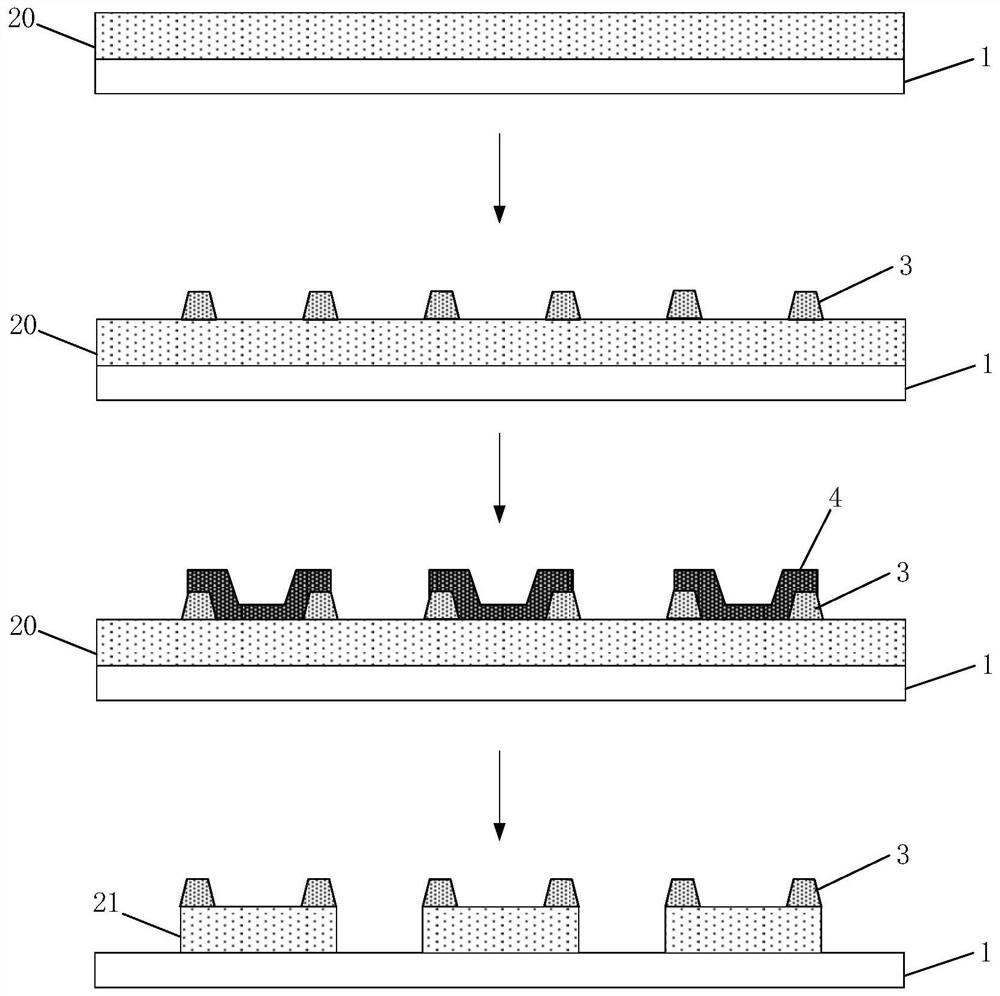

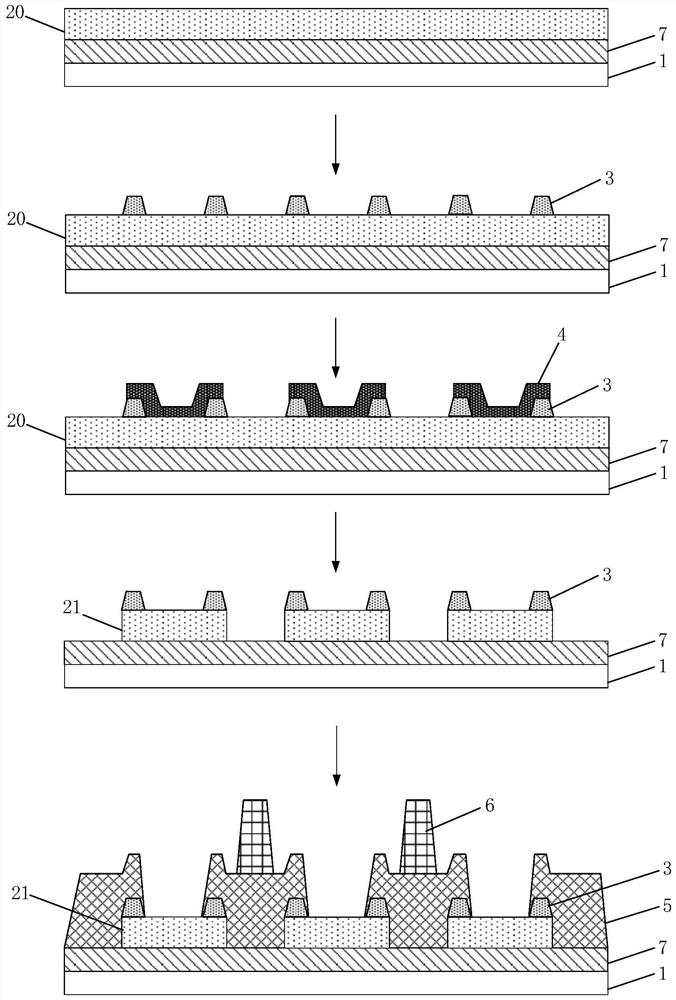

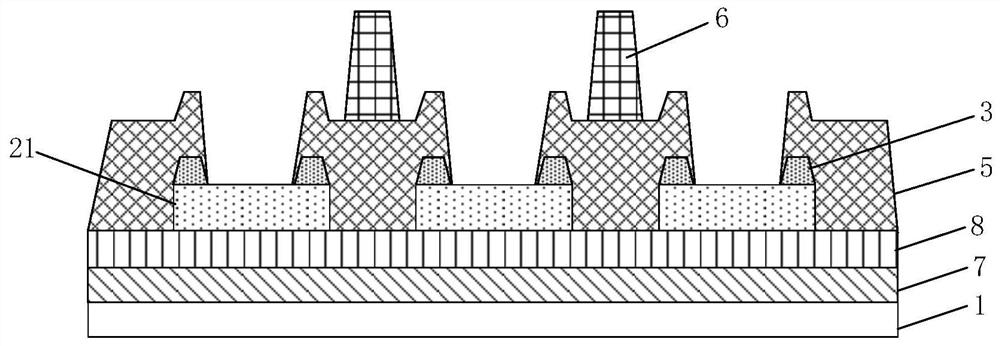

[0065] In order to further illustrate the display substrate and the production method thereof, the display device thereof, the following description is described in detail below.

[0066] In the relevant technique, the specific structure of the AMOLED display device typically includes: a substrate, a pixel circuit layer disposed on a substrate, and a plurality of light-emitting units disposed on one side of the pixel circuit layer to the substrate; wherein the pixel circuit layer comprises an array distribution. The pixel circuit, each of which includes a relatively disposed anode pattern and a cathode pattern, and an organic light-emitting material layer disposed between the two, an anode pattern and a pixel circuit, and each anode pattern has a corresponding pixel. The output electrode of the drive transistor in the circuit is electrically connected. When the AMOLED display device is displayed, the AMOLED circuit provides a driving signal as a corresponding anode pattern, while ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com