Fresh-eating solid food sterilization device and fresh-eating solid food instantaneous sterilization method

A sterilization device and fresh food technology, applied in food preservation, food science, application, etc., can solve the problems of oil contamination, product shape influence, high investment, etc., and achieve the effect of easy operation and good sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

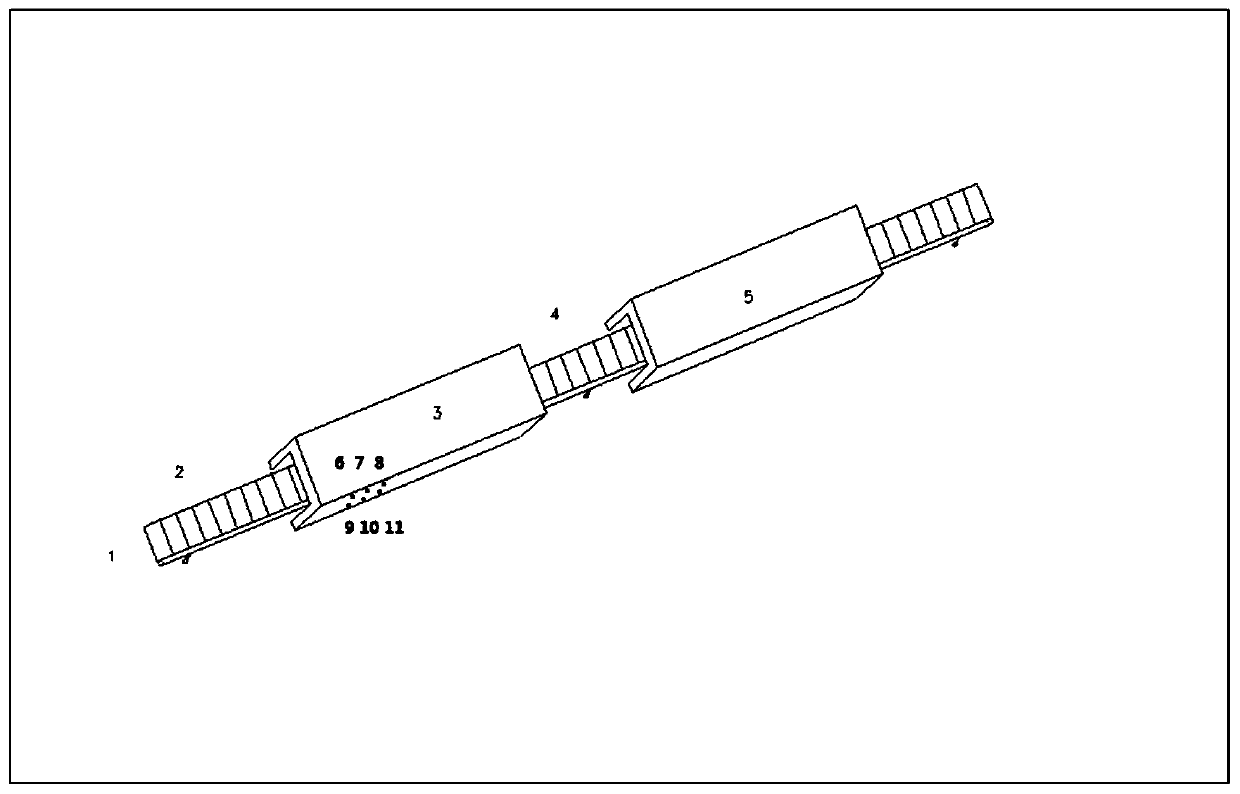

Image

Examples

Embodiment 1

[0046] The fresh noodles are processed into shapes, packed in a high-temperature-resistant composite food bag, vacuumized, sealed by a sealing machine, and packed fresh noodles are obtained.

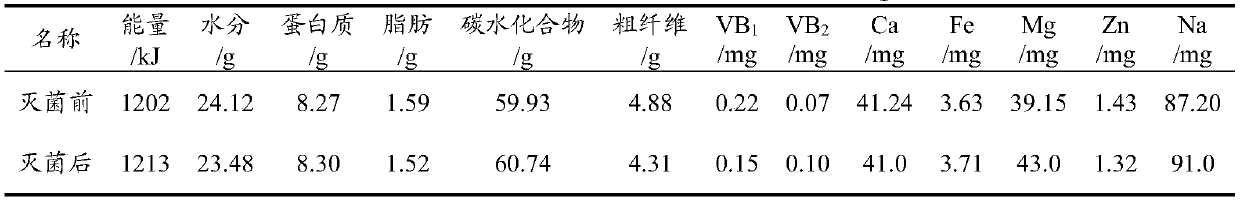

[0047] Open the sterilization box of the fresh solid food sterilization device in advance, adjust the medium temperature sterilization chamber, set the temperature at 100°C, adjust the high temperature sterilization chamber, set the temperature at 200°C, set the conveyor belt speed to 0.1m / s, and turn on the breeze Circulation controller, when the temperature in the sterilization chamber is kept stable at 200°C, the packaged fresh noodles are added to the conveyor belt. After being transported by the conveyor belt, the fresh noodles first enter the medium-temperature sterilization chamber for preliminary preheating, and then enter the high-temperature sterilization chamber. The sterilization chamber is heated to 170°C to 180°C in an instant, and the fresh noodles after passing through the...

Embodiment 2

[0054] After cooling the steamed and matured whole-wheat steamed buns to room temperature, they are packed in high-temperature-resistant composite food bags, vacuumized, and sealed by a sealing machine to obtain packed fresh steamed buns.

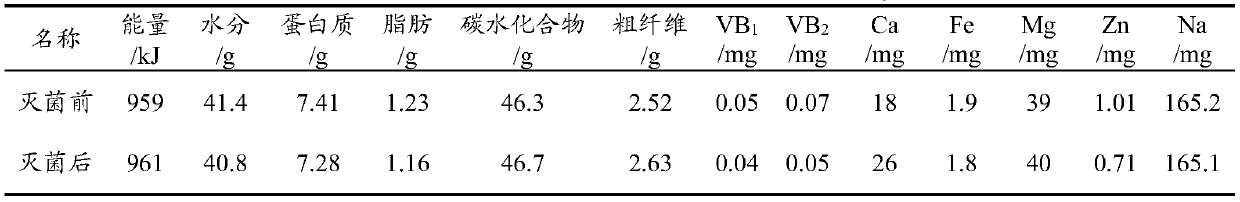

[0055] Open the sterilization box of the fresh solid food sterilization device in advance, adjust the medium temperature sterilization chamber, set the temperature at 100°C, adjust the high temperature sterilization chamber, set the temperature at 250°C, set the conveyor belt speed to 0.2m / s, and turn on the breeze Circulation controller, when the temperature in the sterilization chamber is kept stable at 250°C, the packaged fresh steamed buns are added to the conveyor belt, and after being transported by the conveyor belt, the fresh steamed buns enter the sterilization chamber and are instantly heated to 220-230°C , After the fresh steamed buns passed through the sterilization chamber are cooled, the nutritional content and hygiene standard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com