Primary processing device of silage

A technology for preliminary processing and silage, which is applied in the direction of feed, cutting equipment, agricultural machinery and implements, etc. It can solve the problems of single crushing method, inability to guarantee crushing efficiency, and raw materials follow the rotation movement, so as to achieve guaranteed crushing effect, ingenious structure, Good processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

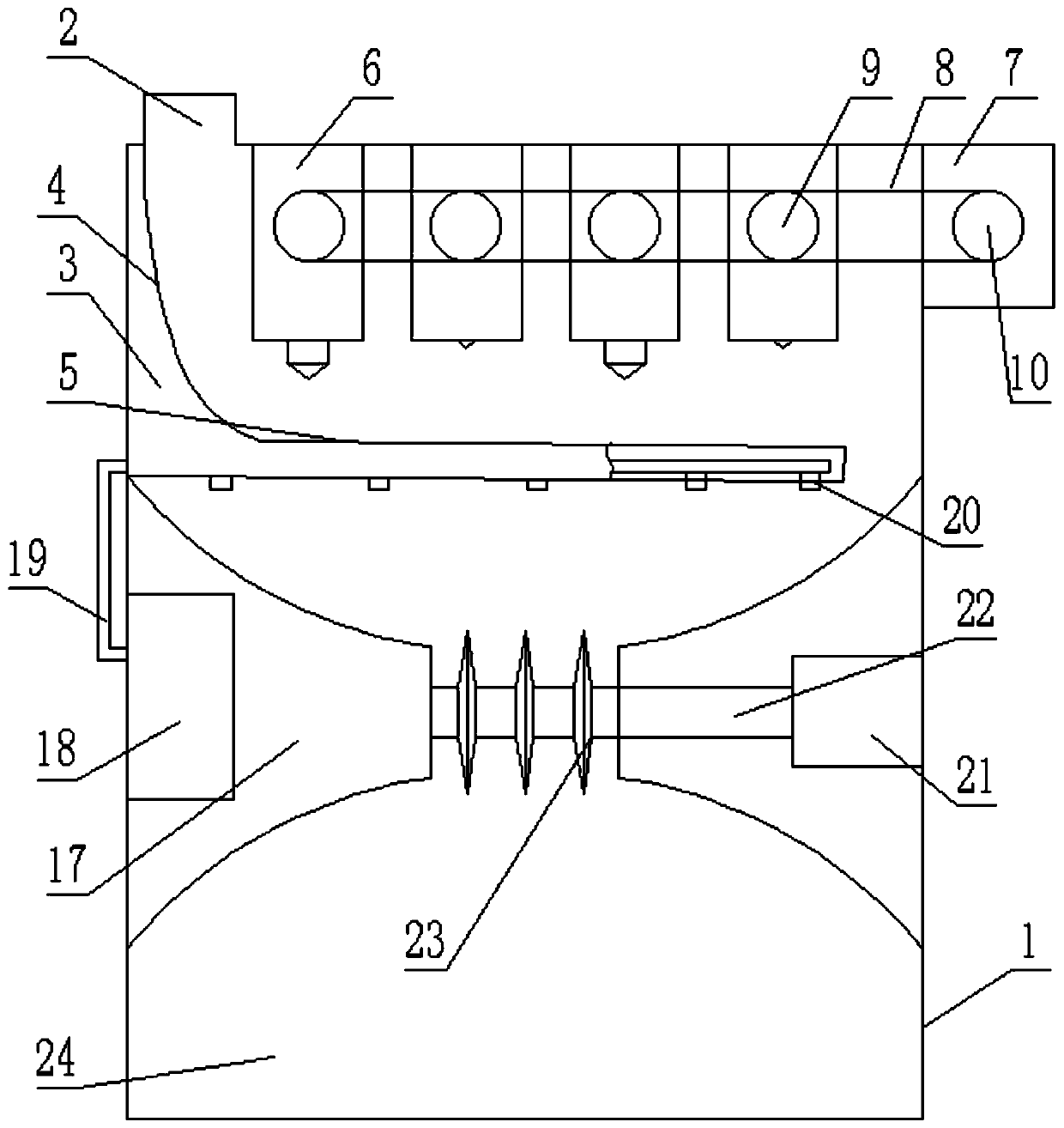

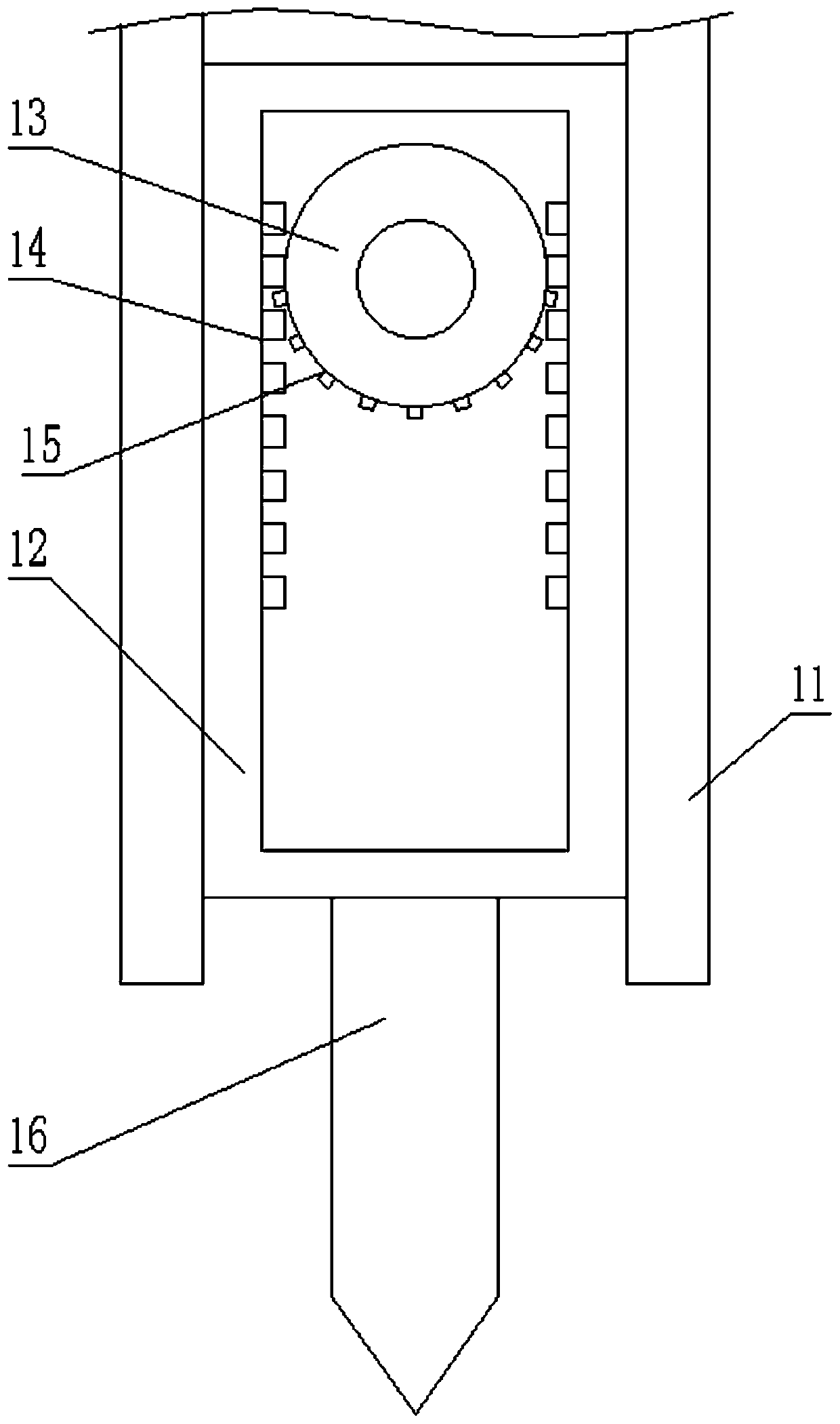

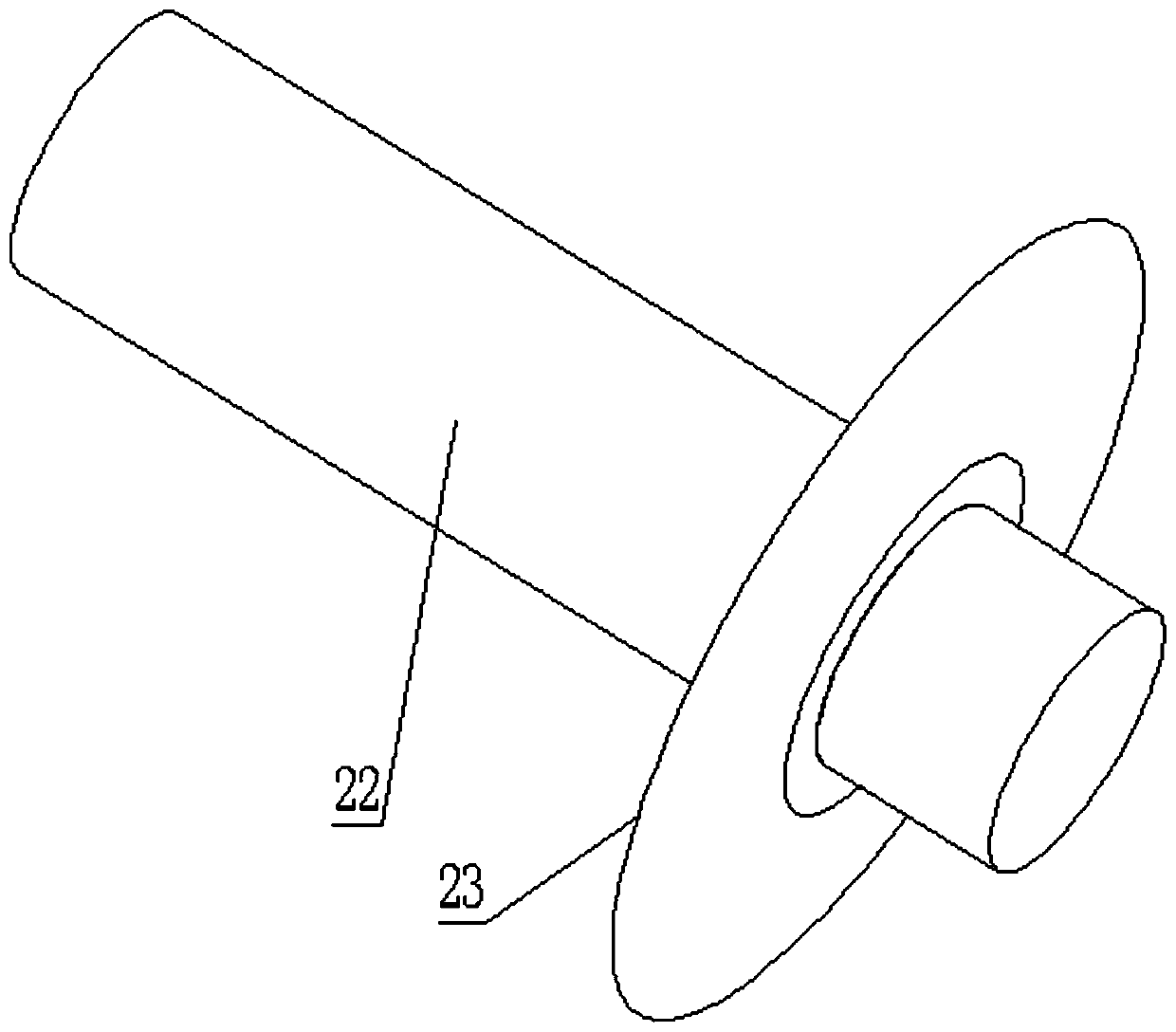

[0019] see Figure 1-3 A preliminary processing device for silage, comprising a processing box 1, the inner bottom of the processing box 1 is a storage room 24, the storage room 24 is used for temporarily storing the silage after preliminary processing, and an inlet is opened at the top edge of the processing box 1 The feed port 2 is used to put raw materials for processing into the processing box 1, and the top plate 3 docked with the feed port 2 is arranged on the top of the processing box 1. Shaped track 4, above the inclined plate 5 is provided with a number of rough cutting devices 6 arranged at equal intervals, and the rough cutting devices 6 initially cut the raw materials input by the feed port 2 during the processing process, and the two adjacent rough cutting devices 6 for staggered slitting, that is, when the rough cutting device 6 in the front performs falling cutting, the rough cutting device 6 at the rear is in a lifted state, thereby ensuring the natural sliding...

Embodiment 2

[0022] On the basis of Embodiment 1, in order to ensure that the raw material can be guided continuously in the two processings, the upper and lower sides of the guide table 17 are arc-shaped to ensure smooth sliding between the two processings, and It can also play a good role in collecting the liquid produced by cutting, avoiding the adhesion of raw materials caused by too much liquid on the guide table 17, thereby avoiding the occurrence of clogging.

Embodiment 3

[0024] On the basis of Embodiment 1, a sieve plate is provided in the storage chamber 24, and a vibrating motor is provided on the sieve plate, and the vibrating motor drives the sieve plate to vibrate, and the raw materials that have been preliminarily processed are screened and classified, which is convenient Determine the subsequent processing method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com