Sludge incineration heat collection and recycling device

A sludge incineration and reuse technology, applied in dewatering/drying/concentrating sludge treatment, gas treatment, membrane technology, etc., can solve problems such as inability to utilize heat and waste resources, and achieve the effect of improving production efficiency and reducing raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

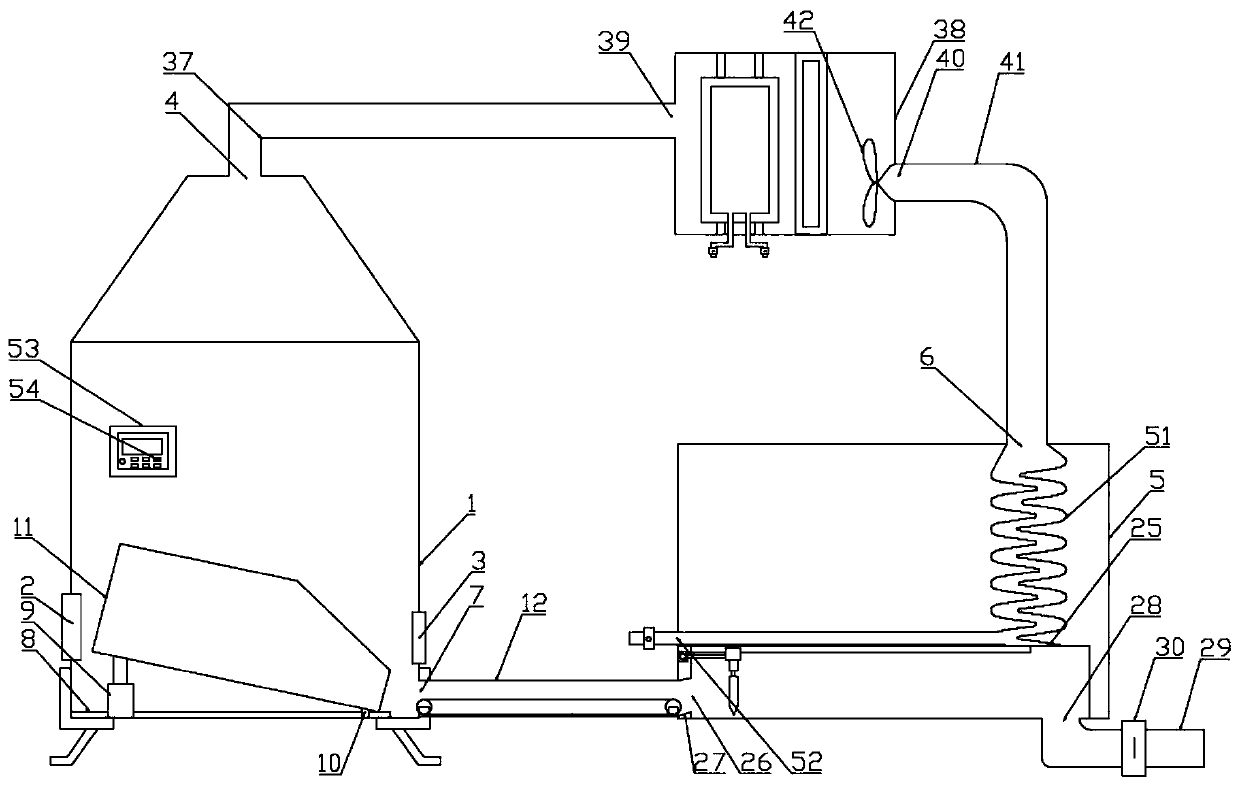

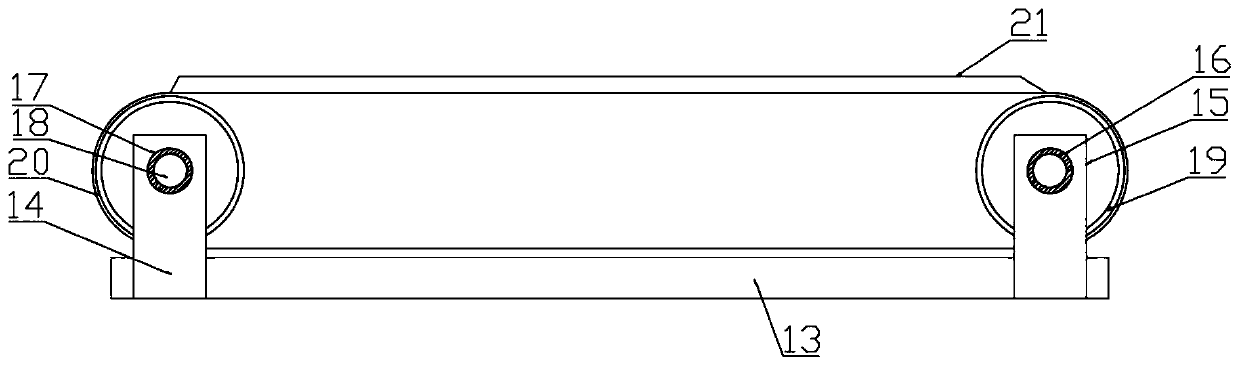

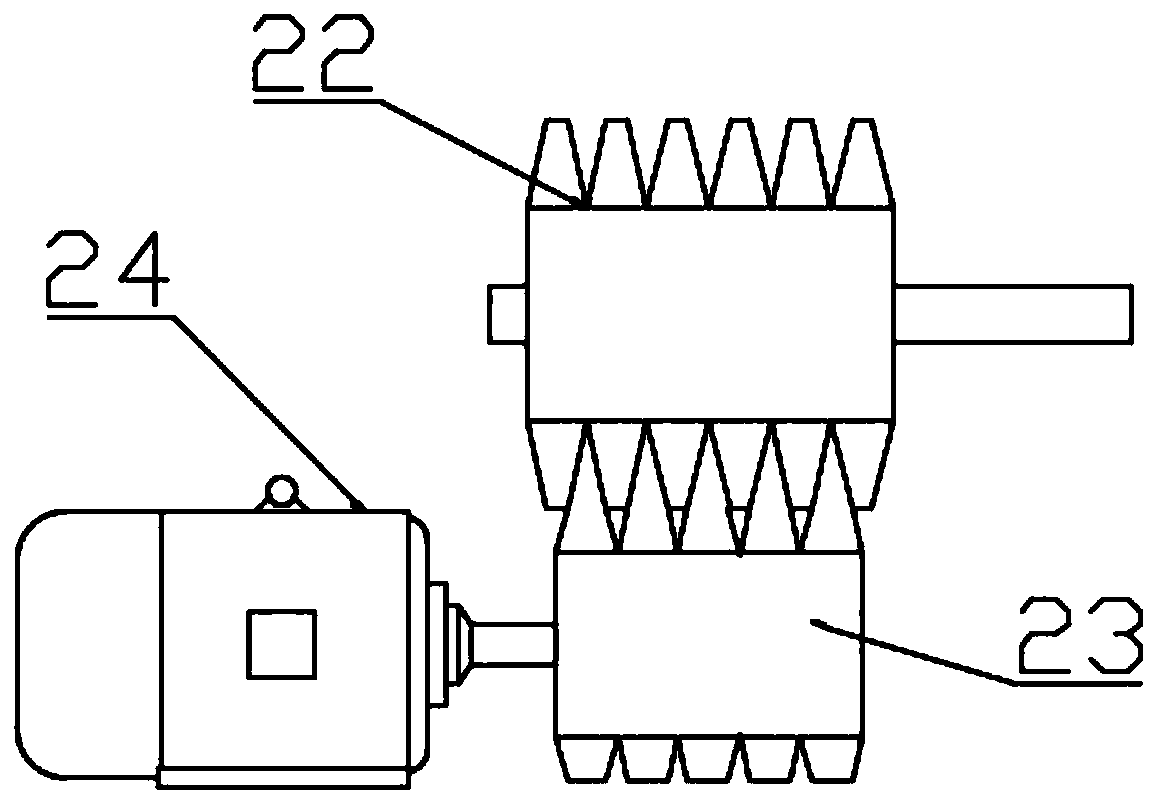

[0022] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 shown.

[0023] In this embodiment, the model of the controller 54 is FX1N-24MR-00, and the signal sending end of the controller 54 is respectively connected with the blower 42, the liquid inlet solenoid valve 47, the liquid outlet solenoid valve 48, the first electric telescopic rod 9, the rotating The signal receiving ends of the motor 24, the exclusion solenoid valve 30, the linear motor 32, and the second electric telescopic rod 36 are connected for control.

[0024] The invention of this application lies in the structural design of the smoke collection and processing device and the intake heating device, combined with the attached figure 1 And attached Figure 4 , the smoke collection and processing device comprises a smoke collection conduit 37, one end of the smoke collection conduit 37 is fixedly installed on the smoke discharge port 4, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com