Microporous polymer coated hydrophilic resin and application thereof in glycopeptide enrichment

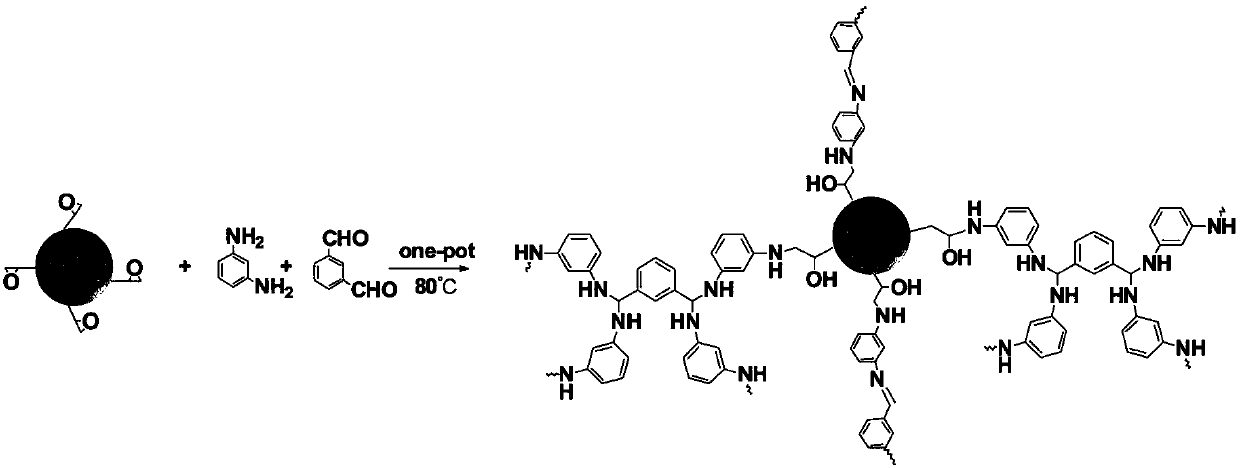

A technology of hydrophilic resin and microporous polymer, which is applied in the field of preparation of hydrophilic resin, can solve the problems of non-glycopeptide interference and low signal of glycopeptide, and achieve the synthesis route with fewer steps, cheap reaction conditions, and the preparation process green flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

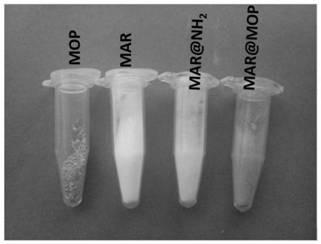

Embodiment 1

[0029] (1) Prepare porous epoxy resin microspheres by seed swelling method, as follows:

[0030]Solution A: Prepare 1 L of absolute ethanol solution containing 20 g / L of polyvinyl alcohol and 20 g / L of non-ionic surfactant Triton X-100. Solution B: prepare 16 mL of 3 g / L azobisisobutyronitrile in styrene. Under a nitrogen atmosphere, slowly add solution B to 64mL solution A, stir the resulting mixed system at room temperature at a mechanical stirring speed of 220r.p.m. for 1 hour, then raise the temperature to 70°C, and polymerize for 12 hours to obtain The product polystyrene microspheres were washed three times with absolute ethanol and water successively, and then vacuum-dried at 60° C. for 12 hours before use. Prepare 1 L of aqueous solution containing polyvinyl alcohol as 10 g / L and sodium lauryl sulfate as 2.5 g / L as the water phase solution of the epoxy resin reaction system prepared by seed swelling polymerization. First, add 0.45g of polystyrene microspheres into 15...

Embodiment 2

[0055] (1) Adopt seed swelling method to prepare porous epoxy resin microspheres, concrete steps are with embodiment 1 step (1)

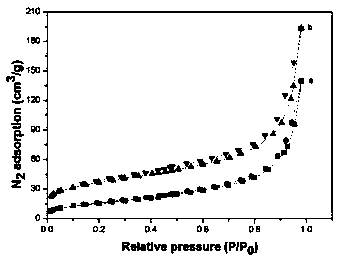

[0056] (2) The preparation of the hydrophilic resin coated with microporous polymers, the specific steps are the same as the step (2) of Example 1, the difference is: the mass of isophthalaldehyde dropped in is reduced to 38mg, i.e. isophthalaldehyde and The molar ratio of m-phenylenediamine was 0.8.

[0057] (3) The product characterization method is the same as (3) in Example 1. The difference between the obtained results is that the specific surface area is 120m 2 / g, the water contact angle of MAR@MOP is 27°.

[0058] (4) Enzymatic hydrolysis of protein samples and (5) application of hydrophilic resin to enrich glycopeptides in protein hydrolyzate are the same as (4) and (5) in Example 1.

[0059] When directly performing mass spectrometry analysis on the IgG enzymatic hydrolysis solution, the mass spectrogram was dominated by non-glycopeptid...

Embodiment 3

[0061] (1) Adopt seed swelling method to prepare porous epoxy resin microspheres, concrete steps are with embodiment 1 step (1)

[0062] (2) The preparation of the hydrophilic resin coated with microporous polymers, the specific steps are the same as the step (2) of embodiment 1, the difference is: the m-phthalaldehyde quality of dropping is reduced to 24mg, that is, m-phthalaldehyde and The molar ratio of m-phenylenediamine was 0.5.

[0063] (3) The product characterization method is the same as (3) in Example 1. The difference between the obtained results is that the specific surface area is 100m 2 / g, the water contact angle of MAR@MOP is 30°.

[0064](4) Enzymatic hydrolysis of protein samples and (5) application of hydrophilic resins to enrich glycopeptides in the enzymatic hydrolyzate of proteins are the same as steps (4) and (5) in Example 1.

[0065] When mass spectrometry was performed directly on the IgG enzymatic hydrolysis solution, the mass spectrogram was domi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com