Method of preparing Pt/KL catalyst for alkane aromatization by using spongy platinum as platinum source

A sponge platinum and paraffin technology, applied in the field of KL zeolite catalysis, can solve the problems of expensive platinum-containing compounds, large demand for platinum-containing compounds, high catalyst cost, etc., and achieve excellent paraffin aromatization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

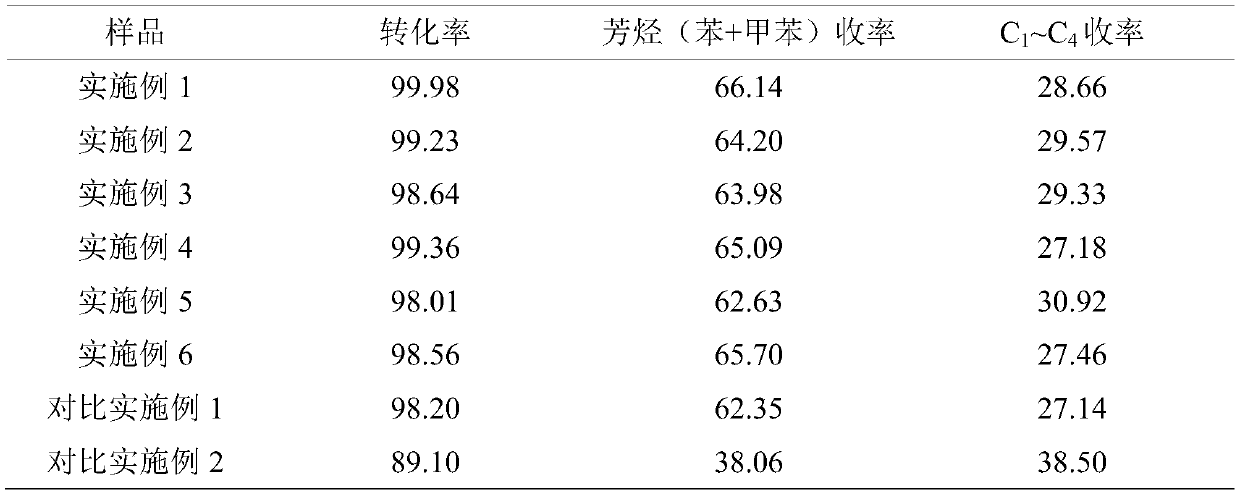

Examples

Embodiment 1

[0037] (1) Put 1g of platinum sponge in 50ml of aqua regia prepared in advance (according to the volume ratio of concentrated hydrochloric acid and concentrated nitric acid: 3:1), and heat to boiling until the platinum sponge is completely dissolved.

[0038] (2) Add a large amount of distilled water to the solution that has fully dissolved sponge platinum in (1), then heat and concentrate, add a large amount of distilled water after concentration, continue to concentrate, repeat for many times, until the solution that boils no longer produces acid mist; Finally The solution was concentrated to about 50ml.

[0039] (3) Adding 0.3g concentration of hydrazine hydrate to the solution obtained in (2) is 85wt.%, and mix uniformly; the solution added with hydrazine hydrate is heated to 70° C., until the reduction reaction is completed, and the hydrazine hydrate containing the divalent Pt element is obtained. Wine red acidic solution.

[0040] (4) Heating the wine red solution obtai...

Embodiment 2

[0043] Repeat Example 1, but change the reducing agent added in step (3) into 0.5g hydrazine hydrochloride, and other operating steps remain unchanged.

Embodiment 3

[0045] Repeat Example 1, but the solution after adding hydrazine hydrate in step (3) is heated to 50° C., and other operating steps remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com