Redwood furniture cleaning fluid

A mahogany furniture and cleaning liquid technology, which is applied in the direction of detergent compounding agent, detergent composition, organic washing composition, etc., can solve the problem of affecting the appearance and service life of mahogany furniture, the cleaning effect of cleaning liquid is not ideal, and the paint damage on the surface of furniture and other problems, to achieve the effect of excellent cleaning effect, simple preparation method and low production investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

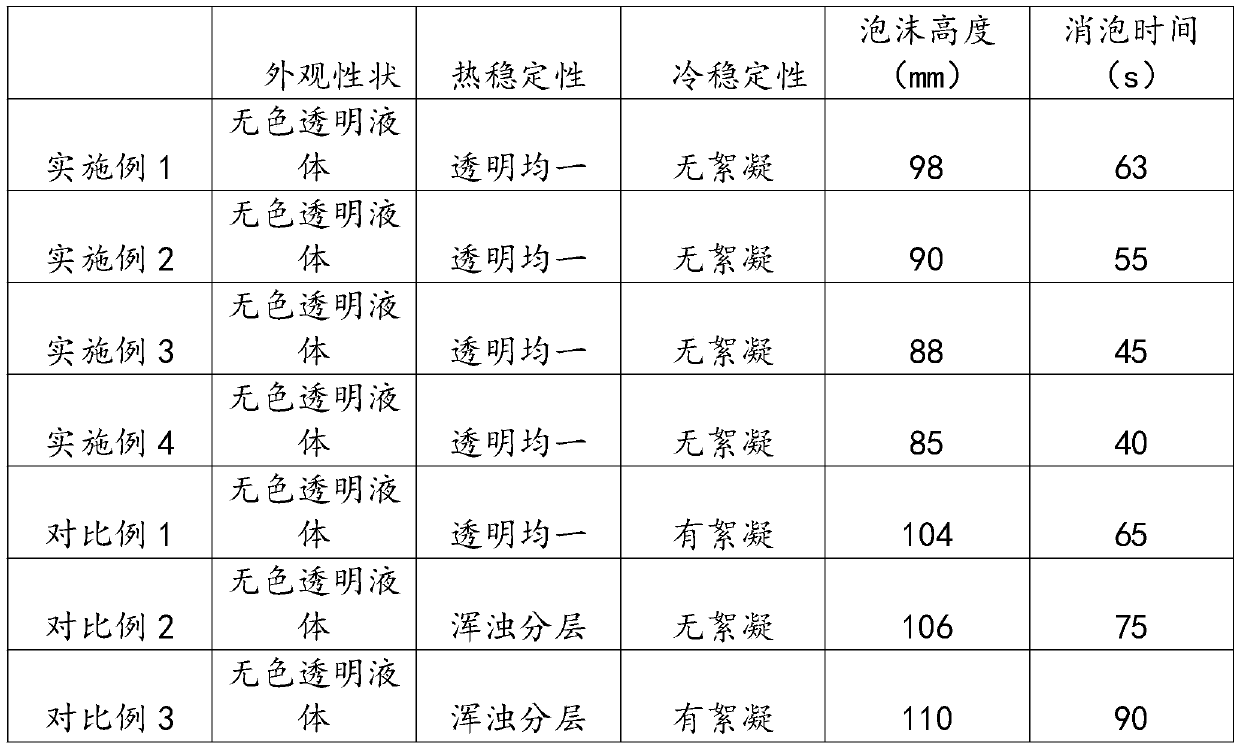

Examples

Embodiment 1

[0028] A kind of mahogany furniture cleaning liquid, is made of following raw material by weight: 10 parts of bentonite, 15 parts of modified nano-microcrystalline cellulose, 20 parts of anthracene oil, 8 parts of sodium dodecylbenzenesulfonate, 25 parts of glycerol , 40 parts of deionized water, 10 parts of natural beeswax, 3 parts of sodium gluconate, 12 parts of silicone oil emulsion;

[0029] This mahogany furniture cleaning solution is made by the following method:

[0030] Step S1, pretreatment: put bentonite in a muffle furnace for calcination at 350°C for 1 hour, then add 100mL of 10% sodium chloride solution, heat in a water bath at 70°C for 2 hours, then add 50mL of 20% sodium hydroxide solution into the sodium chloride solution, and raise the temperature to 80°C, ultrasonically, stirred for 20 minutes and filtered, put the activated bentonite in a beaker, rinsed with deionized water until the solution was neutral, filtered again, dried the bentonite in an 80°C dryin...

Embodiment 2

[0040] A cleaning solution for mahogany furniture, made of the following raw materials in parts by weight: 12 parts of bentonite, 16 parts of modified nano-microcrystalline cellulose, 22 parts of anthracene oil, 10 parts of sodium dodecylbenzenesulfonate, 26 parts of glycerin , 45 parts of deionized water, 12 parts of natural beeswax, 5 parts of sodium gluconate, 13 parts of silicone oil emulsion;

[0041] This mahogany furniture cleaning solution is made by the following method:

[0042] Step S1, pretreatment: put bentonite in a muffle furnace for calcination at 350°C for 1 hour, then add 100mL of 10% sodium chloride solution, heat in a water bath at 70°C for 2 hours, then add 50mL of 20% sodium hydroxide solution into the sodium chloride solution, and raise the temperature to 80°C, ultrasonically, stirred for 20 minutes and filtered, put the activated bentonite in a beaker, rinsed with deionized water until the solution was neutral, filtered again, dried the bentonite in an ...

Embodiment 3

[0048] A cleaning solution for mahogany furniture, made of the following raw materials in parts by weight: 13 parts of bentonite, 18 parts of modified nano-microcrystalline cellulose, 26 parts of anthracene oil, 12 parts of sodium dodecylbenzenesulfonate, 28 parts of glycerin , 50 parts of deionized water, 14 parts of natural beeswax, 6 parts of sodium gluconate, 14 parts of silicone oil emulsion;

[0049] This mahogany furniture cleaning solution is made by the following method:

[0050] Step S1, pretreatment: put bentonite in a muffle furnace for calcination at 350°C for 1 hour, then add 100mL of 10% sodium chloride solution, heat in a water bath at 70°C for 2 hours, then add 50mL of 20% sodium hydroxide solution into the sodium chloride solution, and raise the temperature to 80°C, ultrasonically, stirred for 20 minutes and filtered, put the activated bentonite in a beaker, rinsed with deionized water until the solution was neutral, filtered again, dried the bentonite in an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com