A kind of preparation method of fe-6.9%si thin ribbon containing rare earth nd

A thin strip and rare earth technology, applied in the field of steel rolling, to reduce the content and size of ordered phases, reduce high-frequency iron loss, and improve texture strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

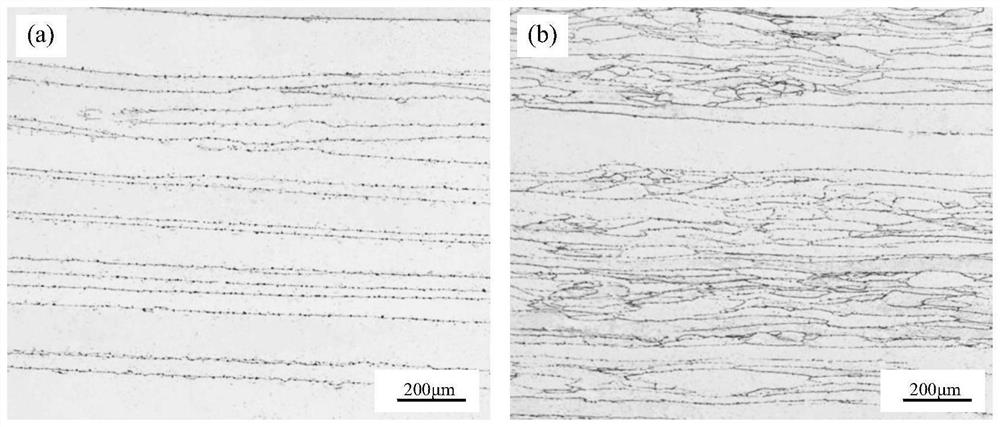

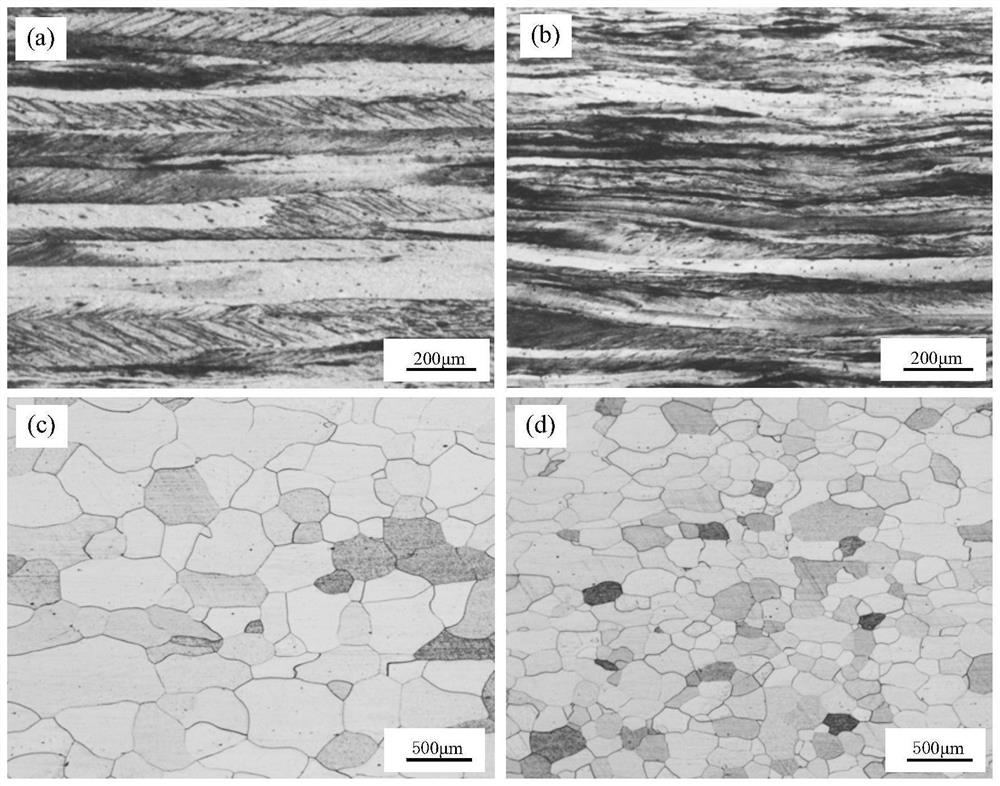

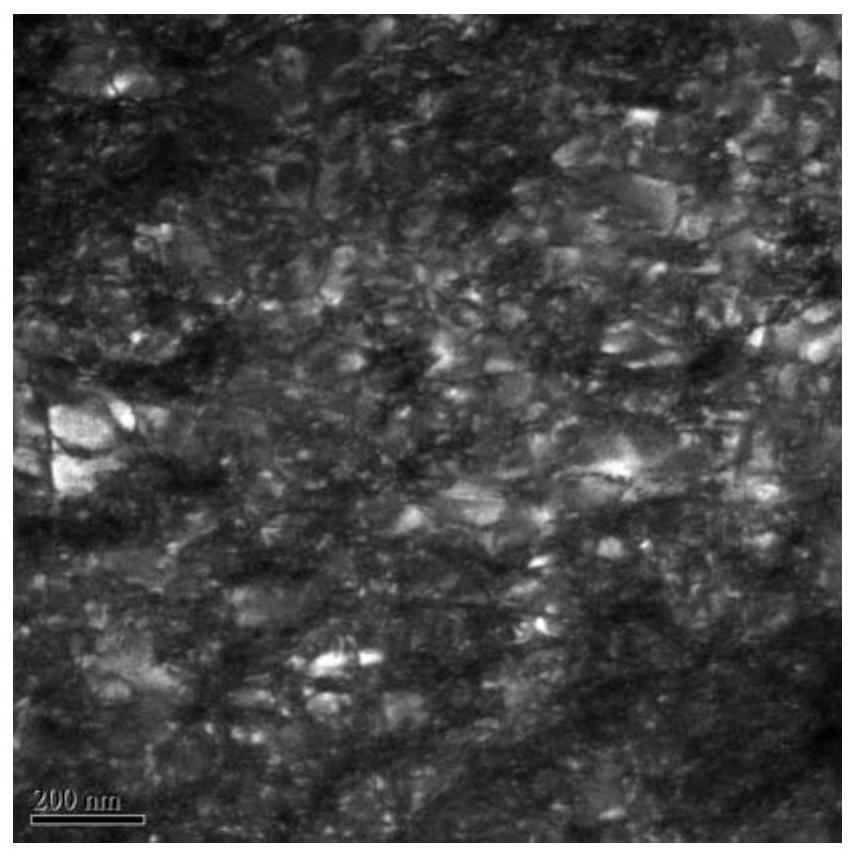

[0033] Vacuum induction furnace is used to cast high-silicon steel ingots, and its chemical composition is as follows: Si 6.95%, Nd 0.032%, C 0.008%, Mn 0.009%, P 0.005%, S 0.004%, N 0.002%, O 0.002% , the balance Fe. At a temperature of 1250°C, after holding for 220 minutes, the billet was free-forged into a 50mm thick billet by air. The heating temperature of the slab hot rolling is 1170°C, the holding time is 110min, and then asynchronous hot rolling is carried out on a reversible asynchronous hot rolling mill with a different speed ratio of 1.2, the lower roll speed is 0.6m / s, and the upper roll speed is 0.78m / s. The final rolling temperature is 880°C, after 10 passes of hot rolling to 3mm, water cooling.

[0034] Pickling with 5% concentration of hydrochloric acid solution and then warm rolling. In the first stage of the warm rolling process, the rolling plate is heated to 650°C, warm rolled to 2mm, the pass reduction rate is 14%, and the rolling force is 230kN. In the...

Embodiment 2

[0038] Vacuum induction furnace is used to cast high-silicon steel ingots, and its chemical composition is as follows: Si 6.91%, Nd 0.038%, C 0.009%, Mn 0.008%, P 0.004%, S 0.003%, N 0.001%, O 0.002% , the balance Fe. At a temperature of 1220°C, after 220 minutes of heat preservation, air free forging was used to form a 50mm thick billet. The heating temperature of the slab hot rolling is 1150°C, the holding time is 100min, and then asynchronous hot rolling is carried out on a reversible asynchronous hot rolling mill with a different speed ratio of 1.2, the lower roll speed is 0.5m / s, and the upper roll speed is 0.6m / s. The final rolling temperature is 890°C, after 10 passes of hot rolling to 2.7mm, it is water-cooled.

[0039] Pickling with 7% concentration of hydrochloric acid solution and then warm rolling. In the first stage of the warm rolling process, the rolling plate is heated to 680°C, warm rolled to 1.7mm, the pass reduction rate is 13%, and the rolling force is 22...

Embodiment 3

[0043] Vacuum induction furnace is used to cast high-silicon steel ingots, and its chemical composition is as follows: Si 6.96%, Nd 0.043%, C 0.008%, Mn 0.009%, P 0.004%, S 0.004%, N 0.002%, O 0.002% , the balance Fe. At a temperature of 1200°C, after holding for 210 minutes, it is free-forged into a 50mm-thick billet by air. The heating temperature of the slab hot rolling is 1170°C, the holding time is 90min, and then asynchronously hot rolling, the speed ratio is 1.3, the roll speed of the lower roll is 0.4m / s, and the roll speed of the upper roll is 0.52m / s. The final rolling temperature is 900°C, after 11 passes of hot rolling to 2.3mm, it is then water-cooled.

[0044] Pickling with 7% concentration of hydrochloric acid solution and then warm rolling. In the first stage of the warm rolling process, the rolling plate is heated to 700°C, warm rolled to 1.5mm, the pass reduction rate is 12%, and the rolling force is 210kN. In the second stage, the rolled plate is heated to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com