Prefabricated assembling type support padstone and manufacturing method thereof

A technology of prefabricated assembly and padding, which is used in the erection/assembly of bridges, bridge parts, bridges, etc., can solve the problems of low strength, unqualified surface elevation, and incomprehensible vibration, and achieves simple construction technology, reduced construction costs, The effect of speeding up construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

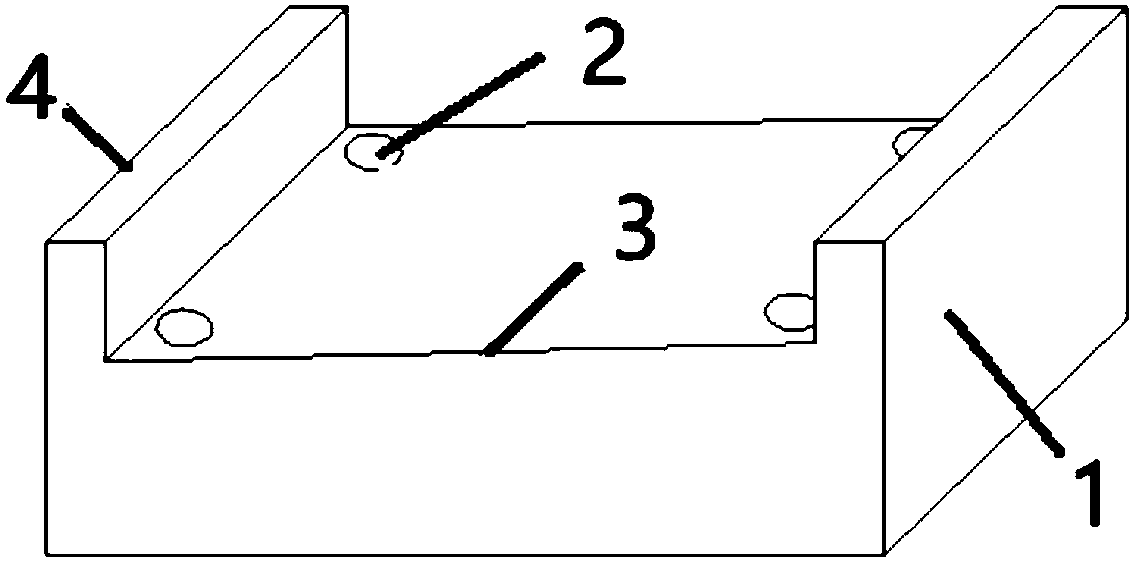

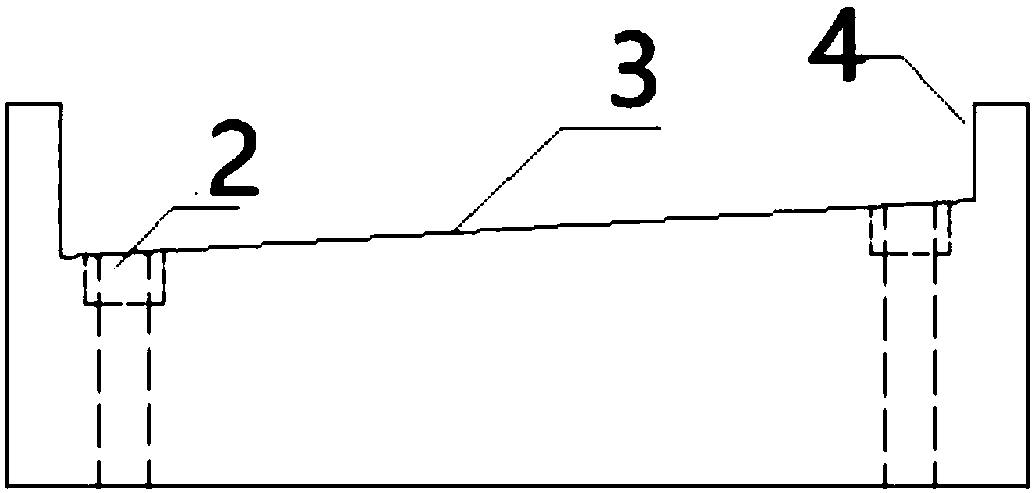

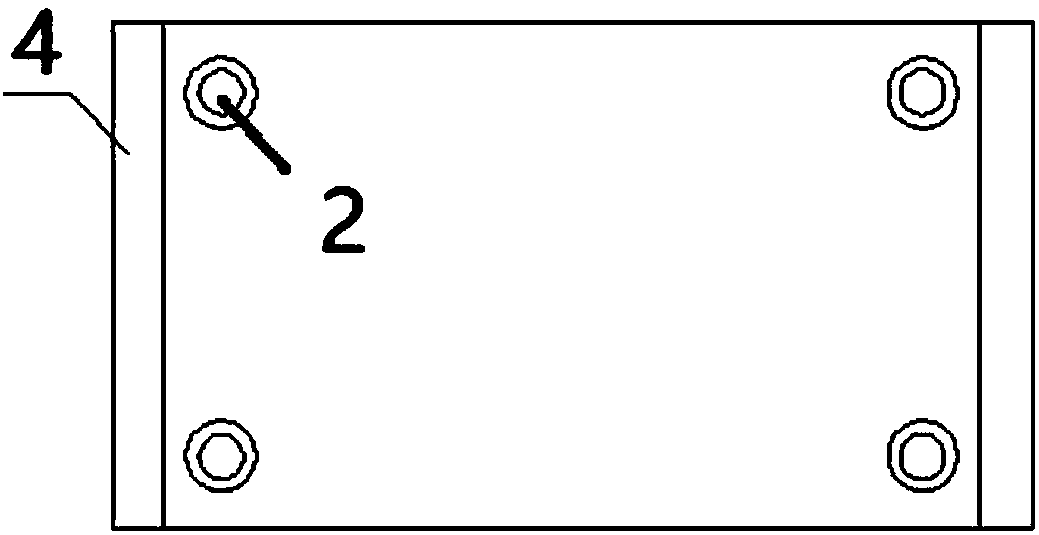

[0020] see Figure 1-3 , a prefabricated and assembled bearing pad, comprising a pad body 1, the material of the pad body 1 is ultra-high performance concrete, and the ultra-high performance concrete has ultra-high strength and is mixed with fibers, so no configuration is required inside The dense steel grid avoids the problem of insufficient density due to intensive vibration of steel bars; ultra-high performance concrete has excellent crack resistance performance, factory production and maintenance ensure the construction quality, and there will be no cracks caused by various reasons on the surface of the pad stone The four corners of the pad stone body 1 are reserved with bolt holes 2, and the bolt holes 2 are circular through holes. Slip edge 4. Bolt rods are reserved on the top of the bridge pier during construction. Clean the top of the pier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com