Preparation method and application of PE modifying material

A modified material, the technology of polymerizing ferric sulfate, which is applied in the field of composite material processing, can solve the problems of strong oxidation resistance, damage, slow erosion of polyethylene, etc., achieve soft and firm texture, soft and uniform texture, improve elongation at break and malleable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

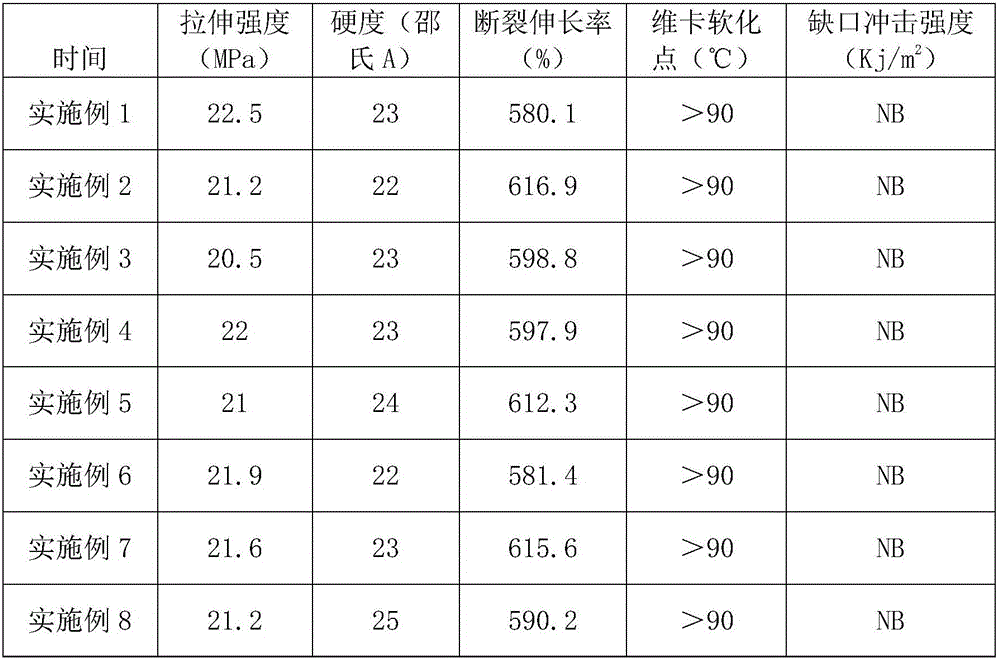

Examples

Embodiment 1

[0034] A preparation method of a PE modified material, consisting of the following components in parts by weight:

[0035]90 parts of PE, 1.5 parts of polyferric sulfate, 0.5 parts of polyaluminum ferric chloride, 1.1 parts of ferrous fluoride, 0.1 parts of ferric citrate, 0.1 parts of carbon hexoxide, 3 parts of hydrogen superoxide, and 1.5 parts of dihydrogen trioxide.

[0036] Its preparation method is to mix PE with hydrogen superoxide and dihydrogen trioxide at room temperature for 60 minutes under airtight stirring according to parts by weight, and then mix them with polyferric sulfate, polyaluminum ferric chloride, ferrous fluoride, ferric citrate, and carbon hexaoxide. Uniform, made by parallel twin-screw extrusion granulation.

Embodiment 2

[0038] A preparation method of a PE modified material, consisting of the following components in parts by weight:

[0039] 95 parts of PE, 2 parts of polyferric sulfate, 1.2 parts of polyaluminum ferric chloride, 2 parts of ferrous fluoride, 0.5 parts of ferric citrate, 0.2 parts of carbon hexoxide, 3.5 parts of hydrogen superoxide, and 2 parts of dihydrogen trioxide.

[0040] Its preparation method is to mix PE with hydrogen superoxide and dihydrogen trioxide at room temperature for 100 minutes under airtight stirring according to parts by weight, and then mix them with polyferric sulfate, polyaluminum ferric chloride, ferrous fluoride, ferric citrate, and carbon hexaoxide. Uniform, made by parallel twin-screw extrusion granulation.

Embodiment 3

[0042] A preparation method of a PE modified material, consisting of the following components in parts by weight:

[0043] 92 parts of PE, 1.5 parts of polyferric sulfate, 0.7 parts of polyaluminum ferric chloride, 1.1 parts of ferrous fluoride, 0.1 parts of ferric citrate, 0.1 parts of carbon hexaoxide, 3.2 parts of hydrogen superoxide, and 1.5 parts of dihydrogen trioxide.

[0044] Its preparation method is to mix PE with hydrogen superoxide and dihydrogen trioxide at room temperature for 60 minutes under airtight stirring according to parts by weight, and then mix them with polyferric sulfate, polyaluminum ferric chloride, ferrous fluoride, ferric citrate, and carbon hexaoxide. Uniform, made by parallel twin-screw extrusion granulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com