Special hole-plugging ink composition for hole filling and printed circuit board

An ink composition, a technology for special plugging, which is applied in the directions of printed circuits, printed circuit manufacturing, inks, etc., can solve the problems of insufficient heat resistance, crack resistance, cavitation resistance, etc., and low degree of double bond cross-linking reaction. , to achieve the effect of excellent cavitation resistance, excellent heat resistance, and excellent crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Preparation of Photocurable Dilute Alkaline Water Developable Resin

[0039] Add o-cresol novolac epoxy resin (Shandong Shengquan 704M), 203 grams, 0.5 grams of hydroquinone, and 250 grams of diethylene glycol ethyl ether acetate (water-soluble solvent) into a three-necked flask, stir, and heat to 100 ° C to Heat and dissolve at 110°C for 1 hour to ensure complete dissolution, then cool down to 90°C, add a solution of 72 grams of acrylic acid and 3 grams of N,N dimethylbenzylamine dropwise, and finish the dripping within three hours. During the process, control the temperature at 90-100°C After the dropwise addition, raise the temperature to 105°C to 110°C and react for 12 hours. The measured acid value is less than 10mgKOH / g, and the temperature of the material is lowered to 90°C. Add 100 grams of tetrahydrophthalic anhydride and keep it at 90-95°C for 4 hours. Spectrometer detection, 1780cm-1 peak disappears, stop the reaction, lower the temperature to room...

Embodiment 2

[0040] Embodiment 2: the preparation of plug hole ink composition

[0041] According to the material ratio listed in Table 1 and Table 2 below (the value of each component is the weight value, and the unit is gram), the plugging ink composition was prepared respectively. Accurately weigh various materials into the container, use a high-speed disperser at a speed of 500 rpm, stir and disperse for 15 minutes, and then grind the composition three times with a three-roll mill to make the fineness of the composition less than 15 microns.

[0042] The formula table of table 1 plug hole ink composition embodiment 1-5

[0043] Element

Example 1

Example 2

Example 3

Example 4

Example 5

Resin A

450

401

446

441

431

Menthane

1

5

1

3

5

tert-butyl peroxyisobutyrate

4

7

1

dipentaerythritol hexaacrylate

45

45

45

45

45

907

50

50

50

50

50

isopropylthi...

Embodiment 3

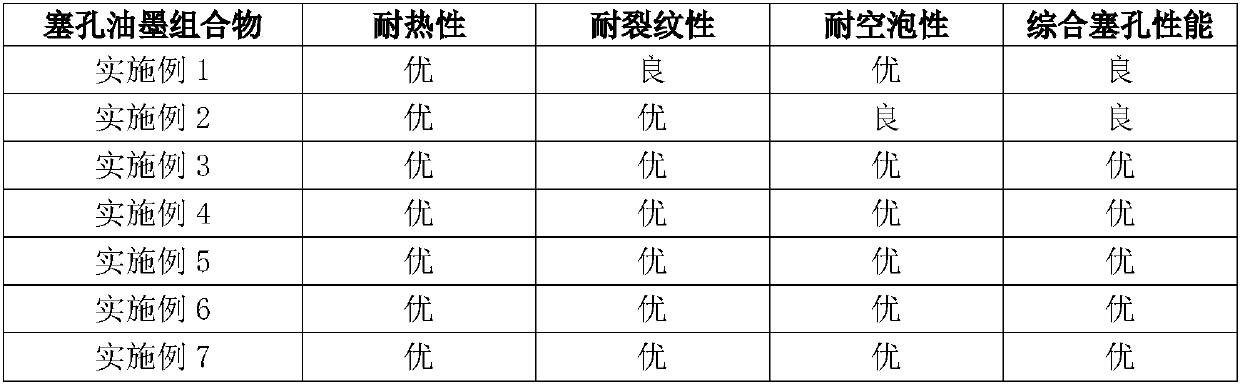

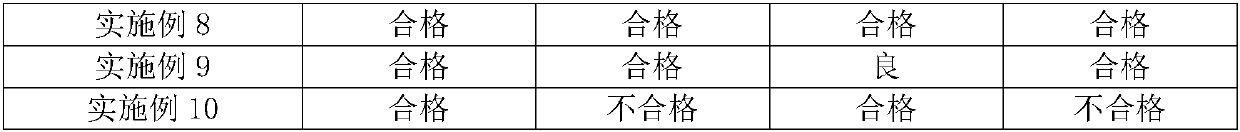

[0054] Embodiment 3 plug hole ink composition property measurement

[0055] According to the plugging ink prepared in Table 1 and Table 2, the plugging experiment was carried out. The specific experimental process is as follows:

[0056] For double-sided substrates with a thickness of 2.0mm, plated through-hole diameters of 0.2mm, 0.3mm, 0.4mm, 0.5mm, and 0.6mm, and a through-hole pitch of 1mm (no pattern is formed, and the number of each through-hole is 50), as the previous Treated pickling + brushing, and then use the semi-automatic printing machine to carry out aluminum sheet hole filling printing with the plugging ink composition of the foregoing examples and comparative examples, dry it in a constant temperature oven at 75 ° C for 50 minutes, cool to room temperature, and use 21 The step exposure scale is 10 grids of energy, and the substrate is exposed, and developed by the conventional development process of the circuit board factory, and then the substrate is post-cure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com