Epoxy resin composition suitable for low-pressure packaging and preparation method thereof

A technology of epoxy resin and composition, which is applied in the field of the preparation of the aforementioned epoxy resin composition, epoxy resin composition, and epoxy resin composition for low-voltage packaging, can solve the problems of leakage, cracking, air holes, etc., and achieve Excellent moisture resistance, high reliability, and low stress effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

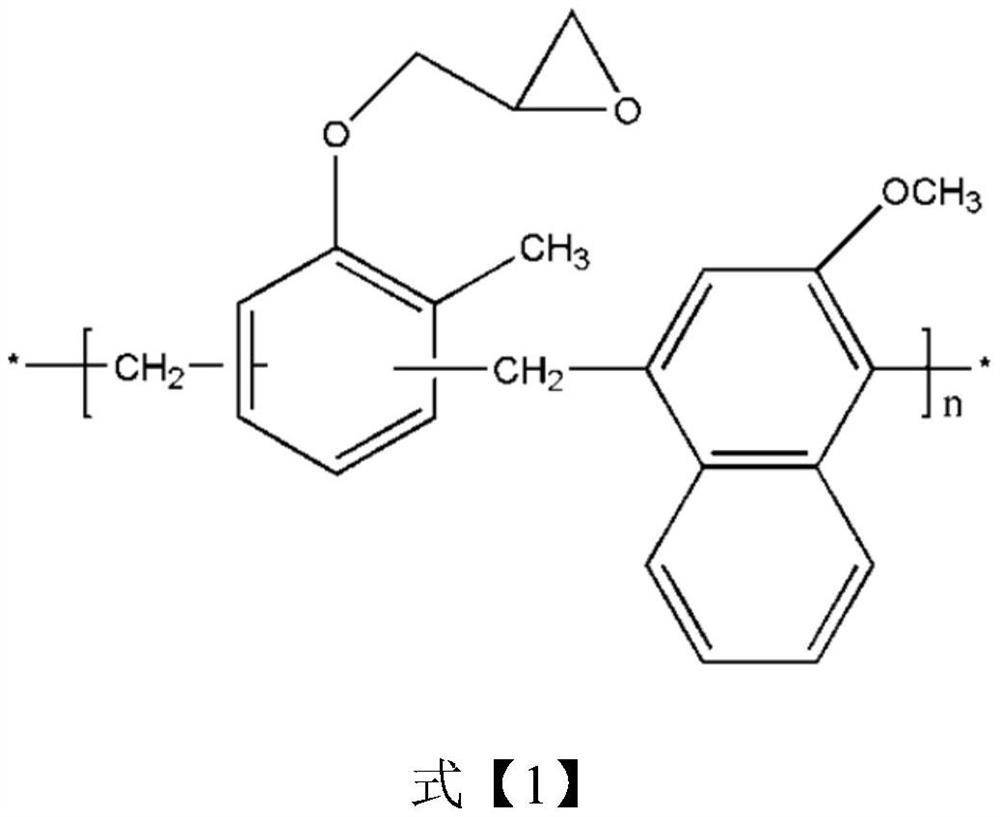

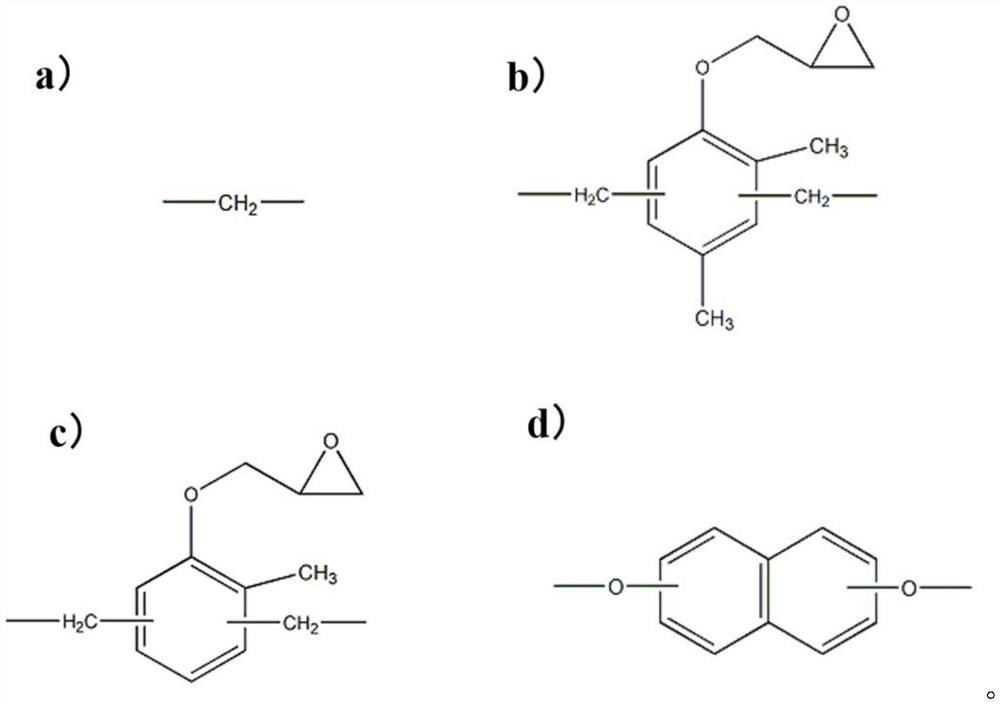

[0032] Embodiment 1, a kind of epoxy resin composition of low pressure encapsulation:

[0033] Each component is weighed according to the ratio recorded in Table 1, Example 1, wherein the formula [1] epoxy resin and the release agent are made into an intermediate in advance, and the formula [1] epoxy resin, formula [3] are added according to the formula ratio. 】Phenolic resin, fused spherical silica powder filler (60% of the total content in the formula), fiber filler (glass fiber filament, diameter 5um, length 3mm), epoxy silane coupling agent, release agent, coloring agent, according to certain The ratio is weighed, mixed evenly, and the mixed material is melted and kneaded in a twin-screw extruder at 80°C, and crushed after being pressed into tablets and cooled. Weigh a certain amount of the above primary extruded material, add the remaining molten spherical silicon micropowder and solidification accelerator according to the ratio of Example 1 in Table 1, melt and knead the...

Embodiment 2

[0034] Embodiment 2, a kind of epoxy resin composition of low pressure encapsulation,

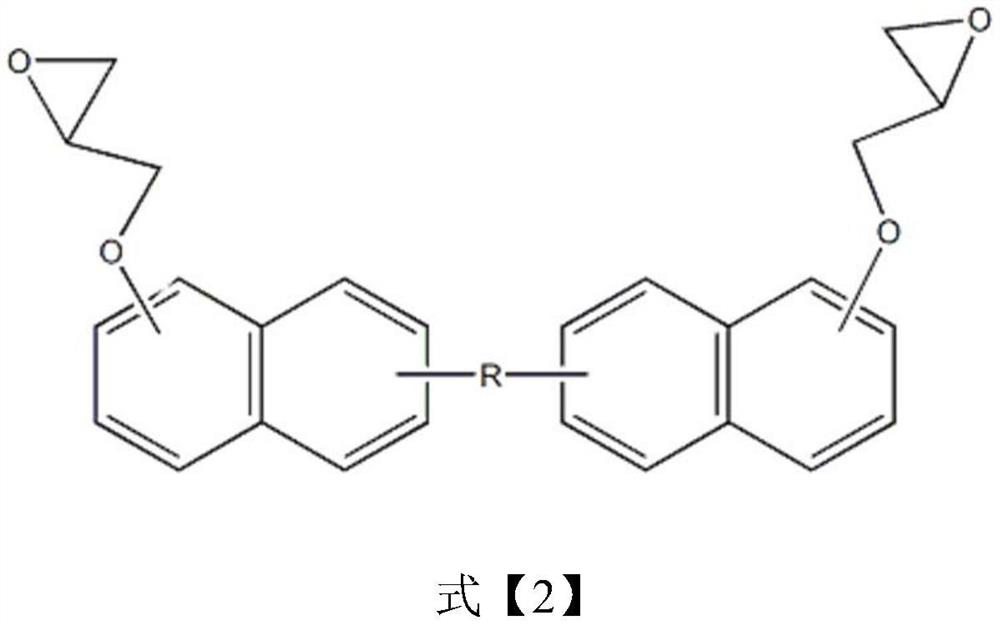

[0035] Each component is weighed according to the proportion of Example 2 in Table 1, wherein the epoxy resin of formula [2] and the release agent are made into intermediates in advance, and the epoxy resin of formula [2] and phenolic resin of formula [3] are added according to the formula ratio , Inorganic filler (the ratio of molten spherical silica powder to molten angular silica powder is 8:1, and the amount of inorganic filler added in the first mixing extrusion is 80%), fiber filler (glass fiber filament, diameter 10um, length 3mm), ring Oxysilane coupling agent, mold release agent and coloring agent are weighed according to a certain ratio and mixed evenly. The mixed materials are melted and mixed in a twin-screw extruder at 80°C, pressed into tablets and then pulverized after cooling. Weigh a certain amount of the above-mentioned primary extruded material, add the remaining inorgani...

Embodiment 3

[0036] Embodiment 3, a kind of epoxy resin composition of low pressure encapsulation,

[0037]Weigh each component according to the ratio of Example 3 in Table 1, wherein formula [1] \ formula [2] epoxy resin and release agent are made into intermediates in advance, and formula [1] \ [2] ring is added according to the formula ratio Oxygen resin, formula [3] phenolic resin, molten spherical silica powder (80% of total content in the formula), fiber filler (glass fiber filament, diameter 10um, length 3mm), epoxy silane coupling agent, release agent, The coloring agent is weighed according to a certain proportion and mixed evenly. The mixed material is melted and kneaded in a twin-screw extruder at 80°C, and crushed after being pressed into tablets and cooled. Weigh a certain amount of the above primary extruded material, add the remaining molten spherical silicon micropowder and solidification accelerator according to the ratio of Example 3 in Table 1, melt and knead the mixed m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com