Tunnel excavation construction process in water-dispersible extremely soft rock stratum

A construction technique and a technology of extremely soft rock, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as inability to fully adapt to local conditions, adverse effects on rock mass stability, difficulty in smooth implementation, etc., and achieve the goal of reducing disintegration Probability, improving reliability and safety, avoiding the effect of water softening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

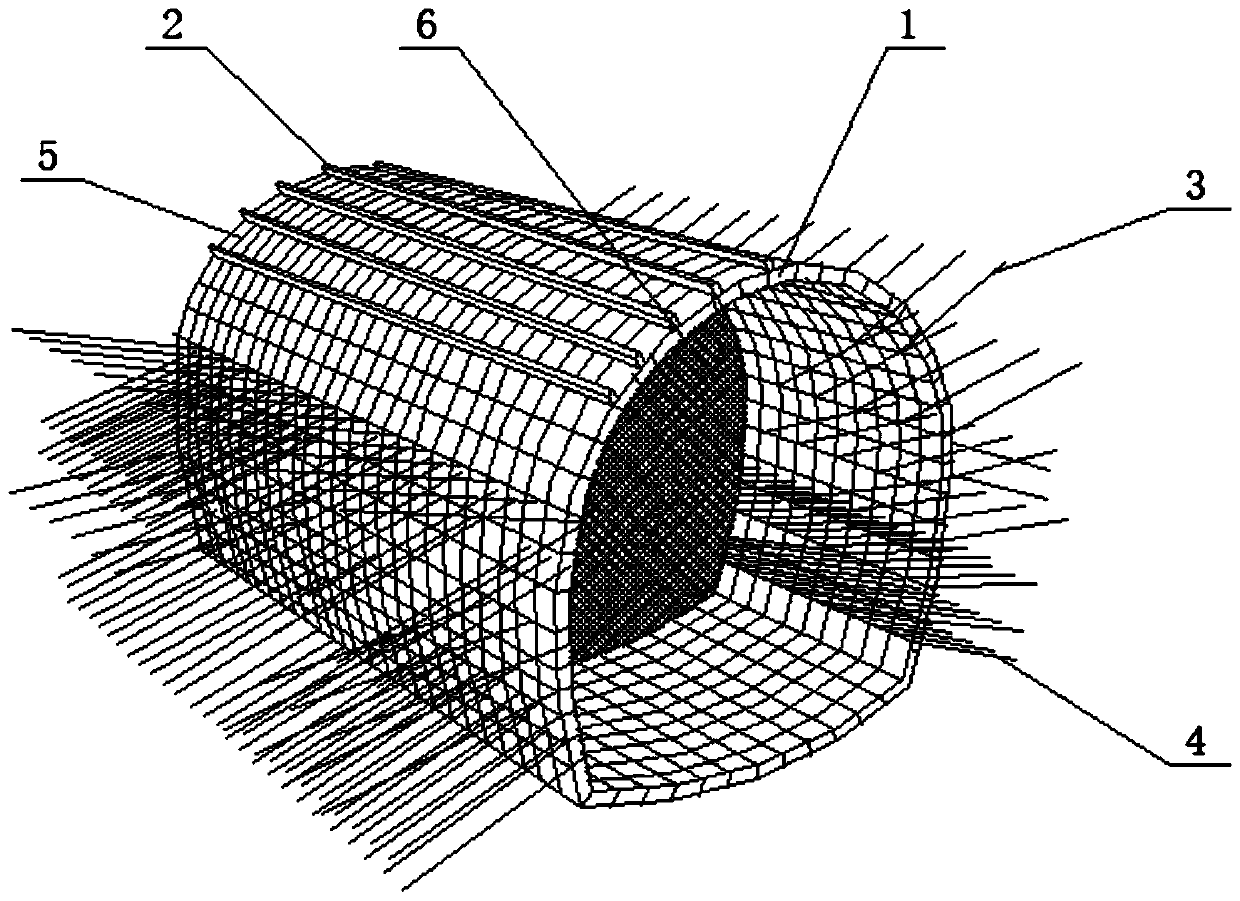

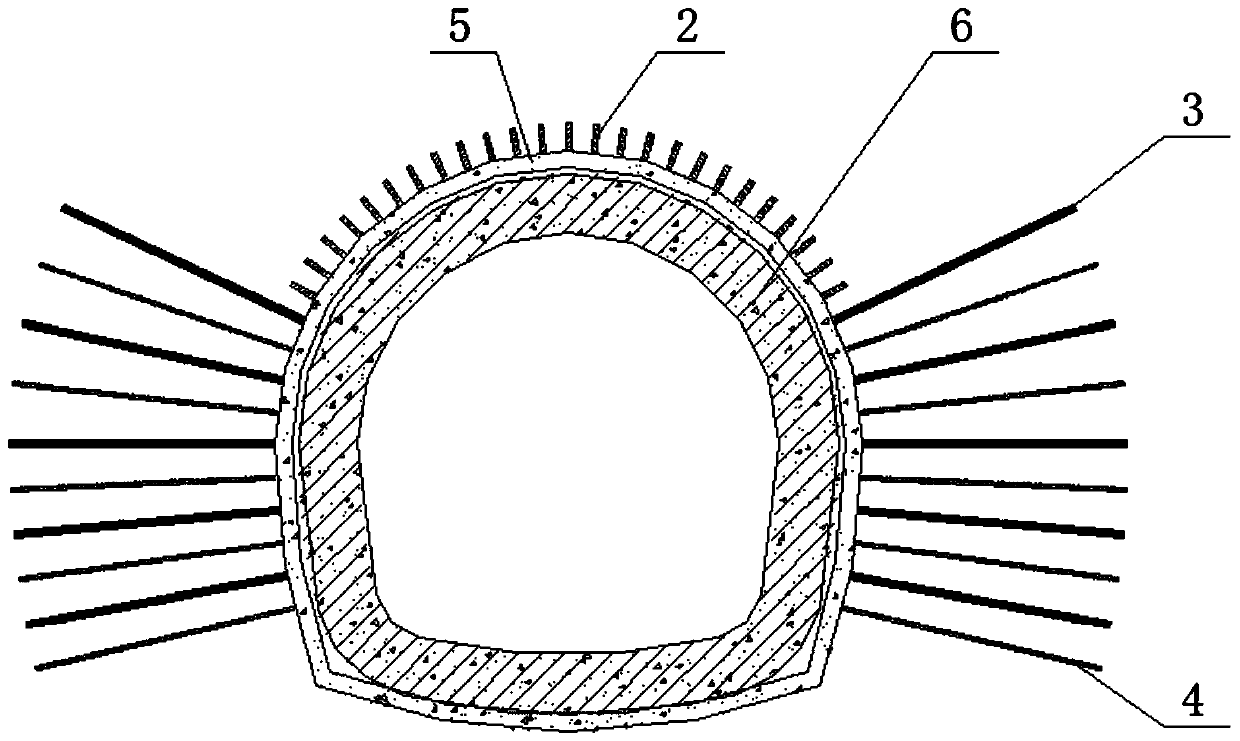

[0029] see Figure 1 to Figure 2 , a tunnel excavation construction process in a very soft rock formation that disintegrates in water, comprising a steel mesh 1, a small lead pipe 2, a system anchor 3, a foot-locking anchor 4, an outer layer of concrete 5 and an inner layer of concrete lining 6, The top of the outside of the reinforced mesh 1 is provided with a small leading guide 2, and both sides of the top of the reinforced mesh 1 are installed with system anchors 3, and both sides of the bottom of the reinforced mesh 1 are provided with locking anchors 4, and the An outer layer of concrete 5 is poured outside, and an inner layer of con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com