Megawatt supercritical carbon dioxide centripetal turbine device

A carbon dioxide and turbine device technology, which is applied to steam engine devices, blade support elements, stators, etc., can solve the problems that ordinary shaft end sealing devices cannot meet the needs of sealing, the safety of shafting is reduced, and the mechanical loss is increased. It is easy to design the structural strength, improve the working ability, and reduce the effect of flow loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

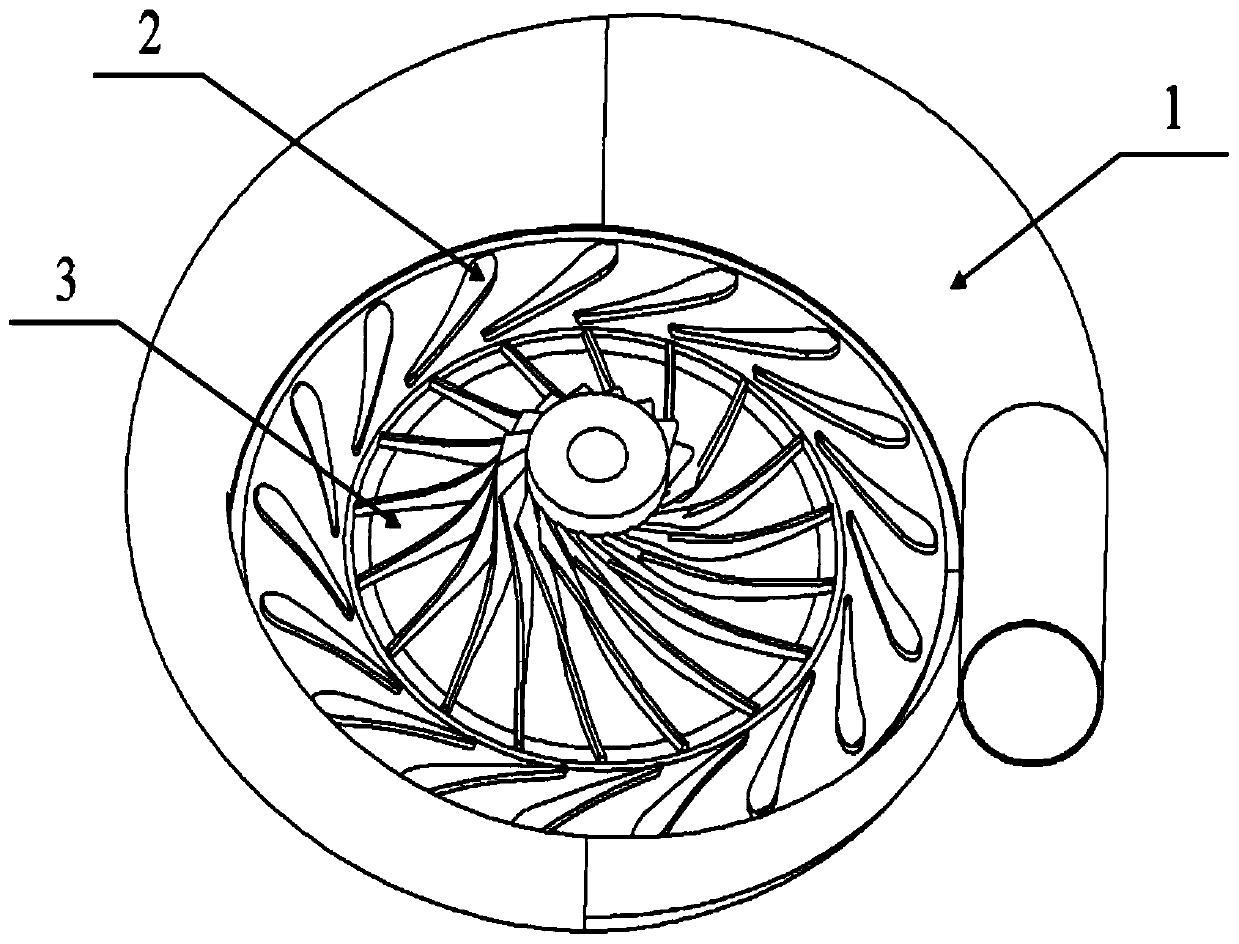

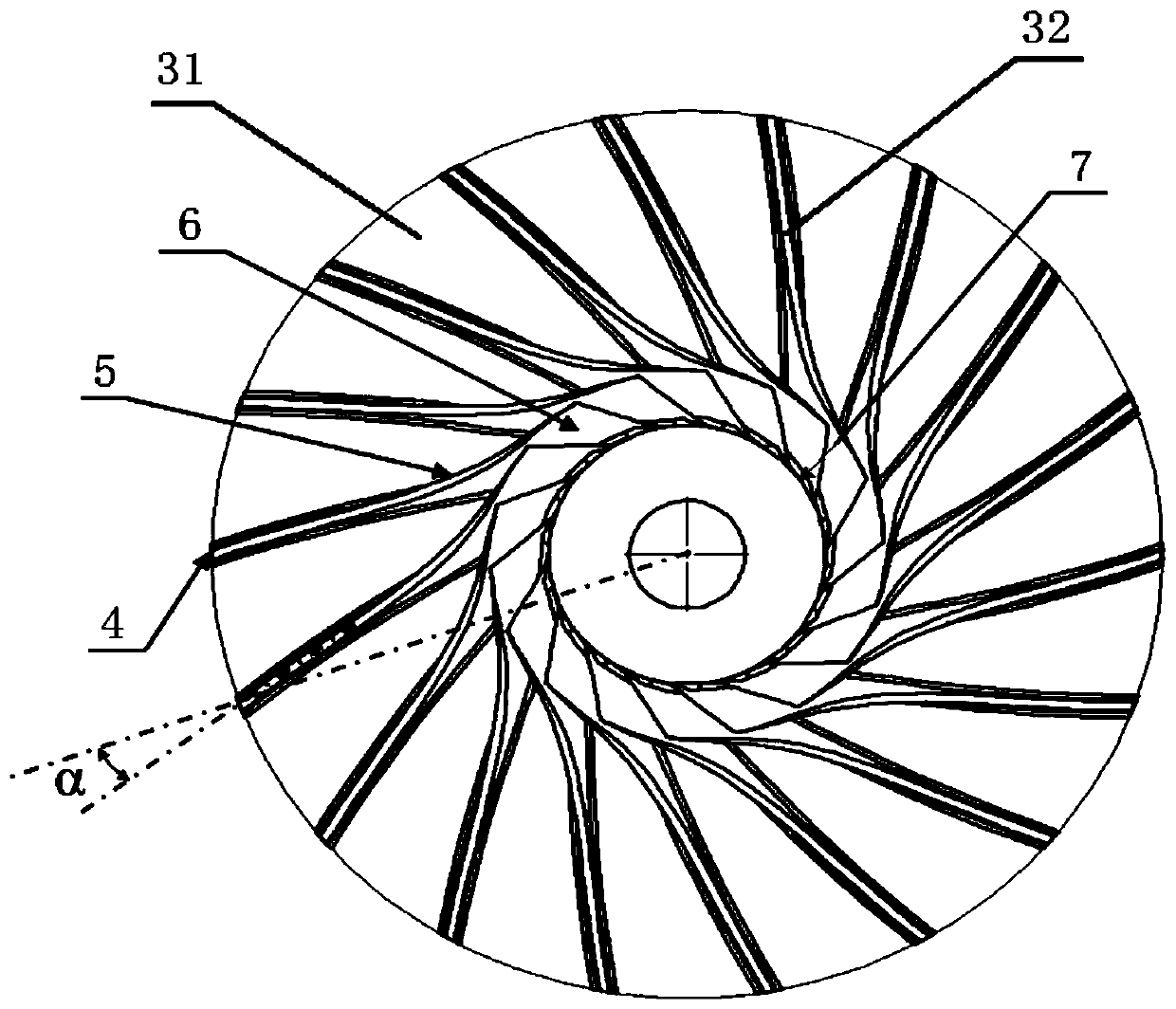

[0027] Embodiment 1: A megawatt supercritical carbon dioxide centripetal turbine device, comprising a volute 1, a nozzle cascade 2 and a turbine impeller 3, the turbine impeller 3 is arranged at the center of the volute 1, and the turbine impeller A plurality of nozzle cascades 2 are arranged on the circumference of 3, and the turbine impeller 3 is composed of a disc 31 and blades 32. The two ends of the blade 32 are respectively provided with a blade inlet 4 and a blade outlet 7, and the end of the blade 32 is close to the blade inlet 4. is the tip of the blade 5, and the other end away from the blade inlet 4 is the blade root 6; in this way, the device uses the volute to guide the intake air and distributes the air evenly along the radial direction. It can effectively reduce the flow loss caused by the fluid flowing in the volute and reduce the flow noise. When working, the supercritical carbon dioxide working medium enters from the volute, and is evenly distributed to the no...

specific Embodiment approach 2

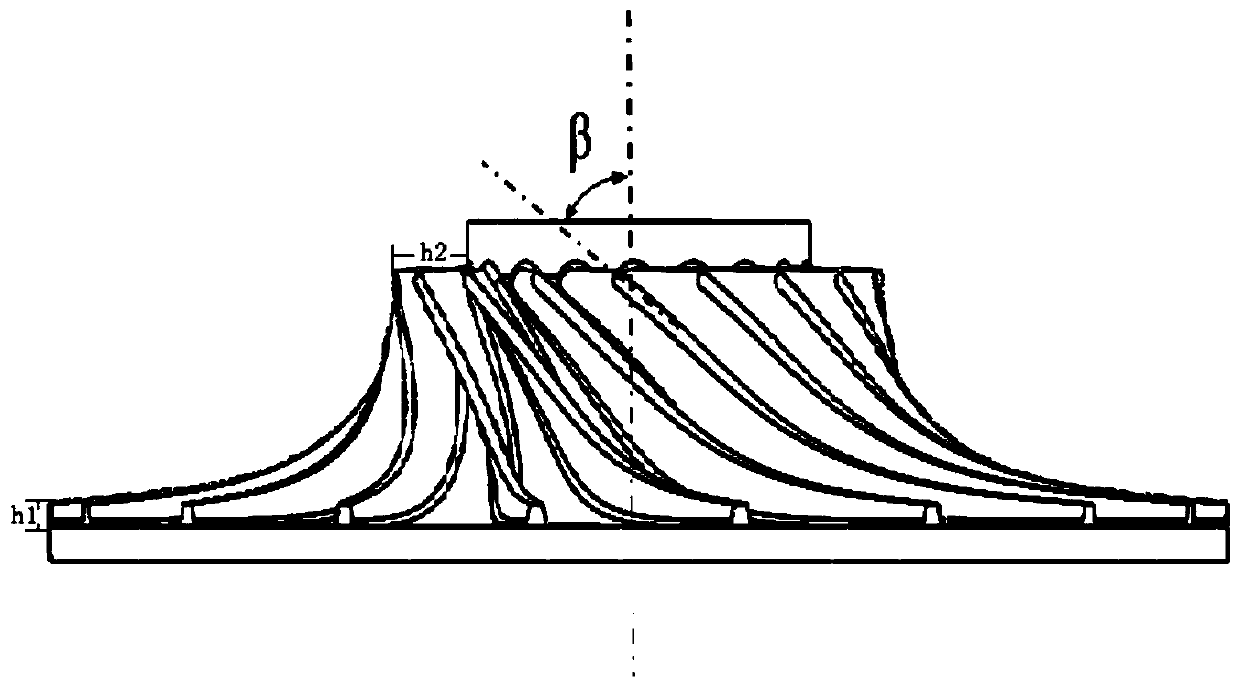

[0028] Specific embodiment 2: a pair of embodiments in conjunction with the description of this embodiment, the angle formed by the impeller blade airfoil on the tangent of the leading edge and the direction of the rotor radius is the inlet blade angle α, and the inlet blade angle α is 70°, so set, and The air intake of the traditional 90° impeller has a large difference. This impeller inlet angle matches well with the nozzle outlet airflow angle, which reduces the aerodynamic loss and greatly improves the operating efficiency of the turbine; the tangent line of the impeller blade airfoil at the trailing edge The included angle formed by the axial direction of the rotor is the outlet blade angle β, and the outlet blade angle β is 53°; in this way, the size of the blade inlet angle α and the outlet blade angle β is set so that the impeller can adapt to large flow conditions. Reduce impact and shedding losses.

specific Embodiment approach 3

[0029] Specific Embodiment Three: This embodiment is described in conjunction with Embodiments 1 and 2. The outer diameter D1 of the blade is 592.7mm, and the axial length h of the blade and the outer diameter D1 of the blade satisfy the following geometric relationship: h=0.16D1, and its specific value is 92mm , further optimized, the number of blades 32 is 18; so set, the diameter of the impeller is 3 to 4 times that of the existing supercritical carbon dioxide centripetal turbine, which can effectively improve the working ability of the impeller and the difference between the axial length of the blade and the outer diameter of the blade relationship, so that the flow condition of the impeller in the axial direction is good; the thickness of the blade top 5 is 6mm, the thickness of the blade root 6 is 10mm, the blade height of the edge of the blade inlet 4 is 8.56mm, and the blade height of the edge of the blade outlet 7 is 38mm ; The diameter D2 of the circumference where th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com