Laser raman and laser fluorescence-based water surface oil film thickness measurement method

A technology of oil film on water surface and measurement method, which is applied in the direction of measuring device, optical device, instrument, etc., can solve the problems of weakening of water Raman scattering intensity, inability to measure oil film, and limited oil film measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

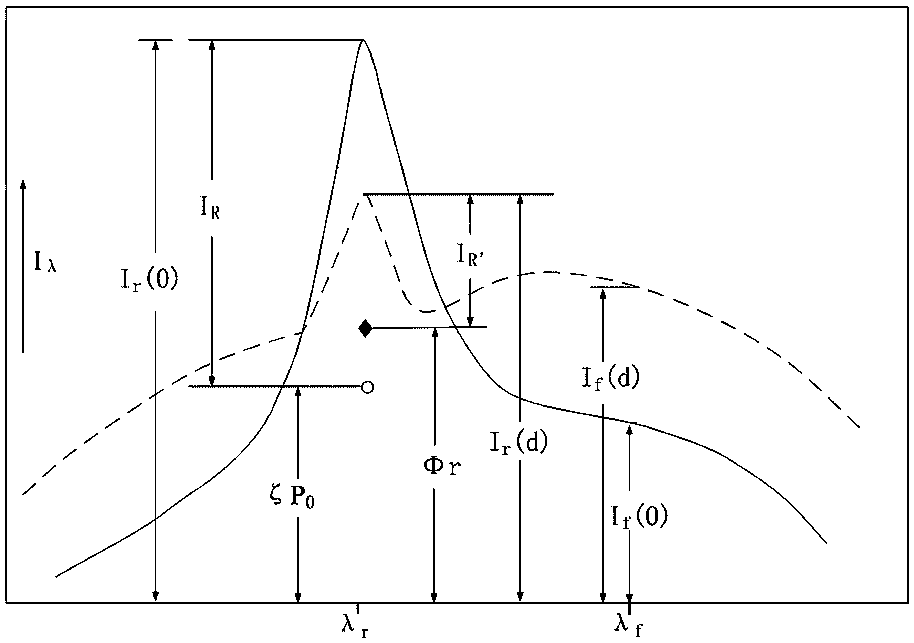

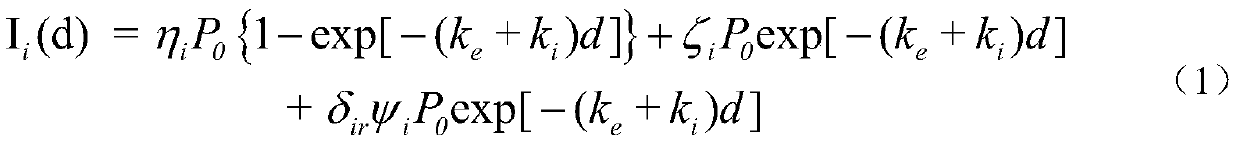

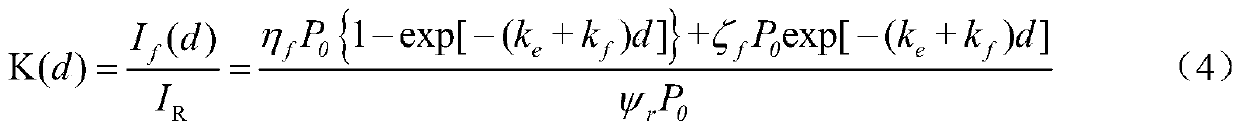

[0015] When the laser spectrum oil film thickness detection system (or other detection equipment in the prior art) emits laser light to irradiate the surface of the oil film on the water surface, while exciting the oil substance to radiate fluorescence, the water will generate Raman scattered light, that is to say, it will The oil film fluorescence signal (referred to as oil fluorescence) and the water Raman scattering signal (referred to as water Raman) are excited. figure 1 are the laser Raman and laser fluorescence spectrum models and their parameters when there is oil film and no oil film on the water surface, where the dotted line represents the spectral curve when there is oil film, and the solid line represents the spectral curve when there is no oil film.

[0016] figure 1 The meanings of the parameters are as follows: P 0 : emitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com