Oil cup liquid level measurement method for range hoods

A technology of liquid level measurement and range hood, which is applied in the direction of liquid/fluid solid measurement, measuring device, engine lubrication, etc. It can solve the problems of reduced service life of detection equipment, low detection accuracy, and large distance measurement error, etc., to achieve Fast calculation speed, high distance accuracy, simple and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

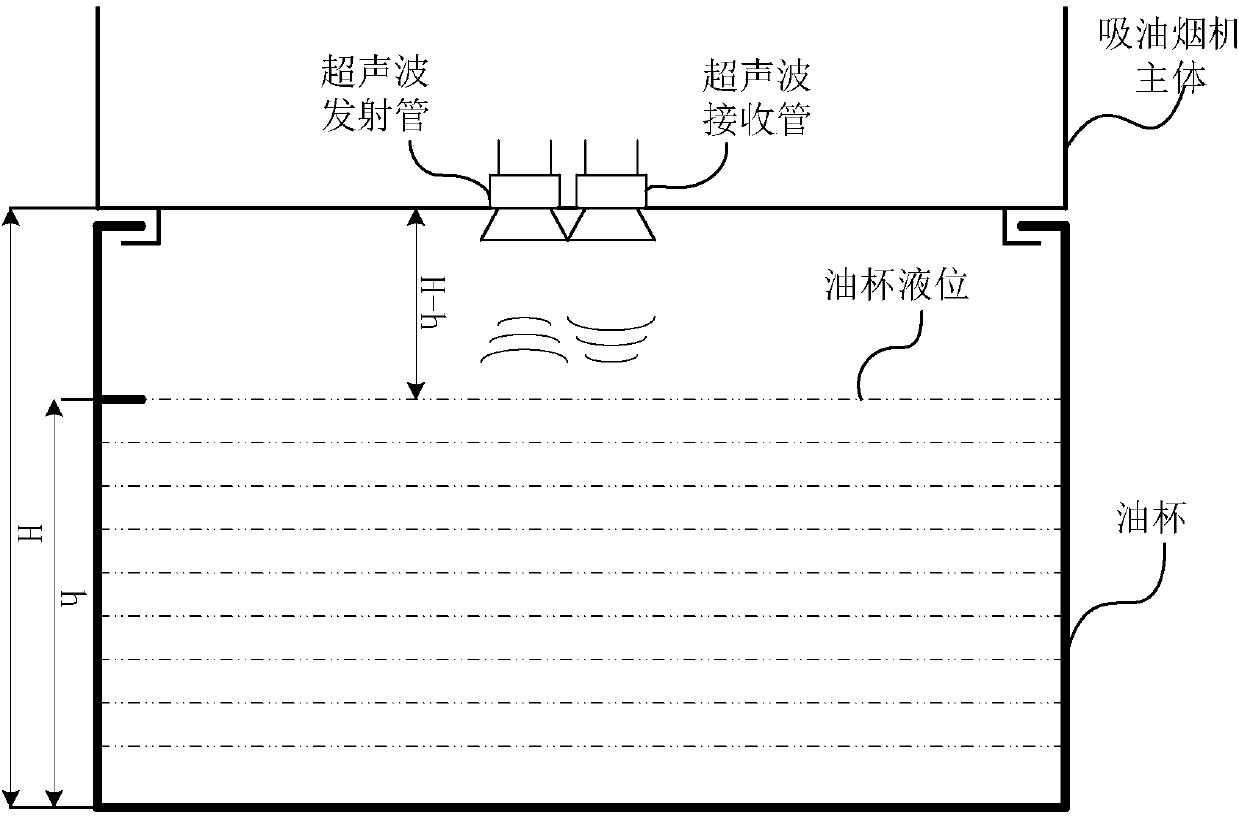

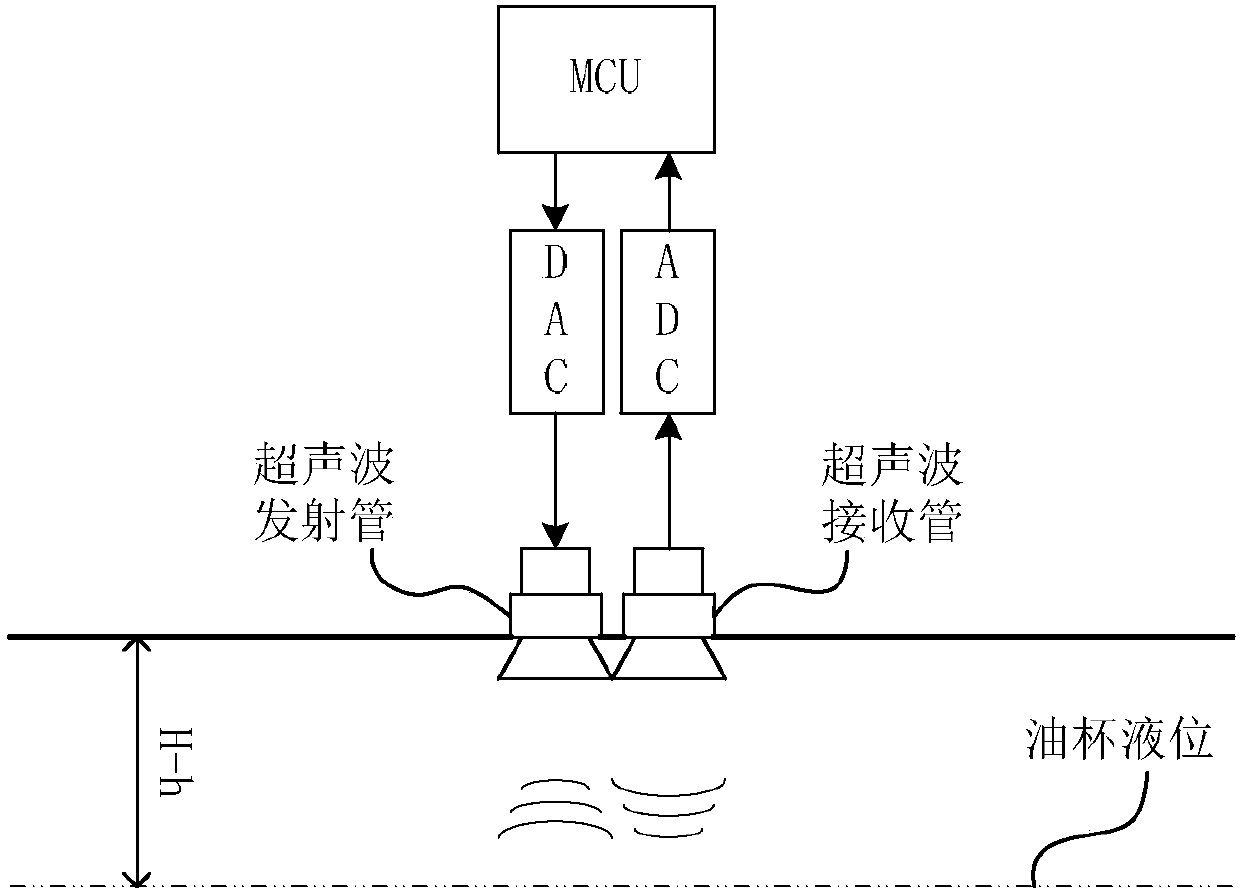

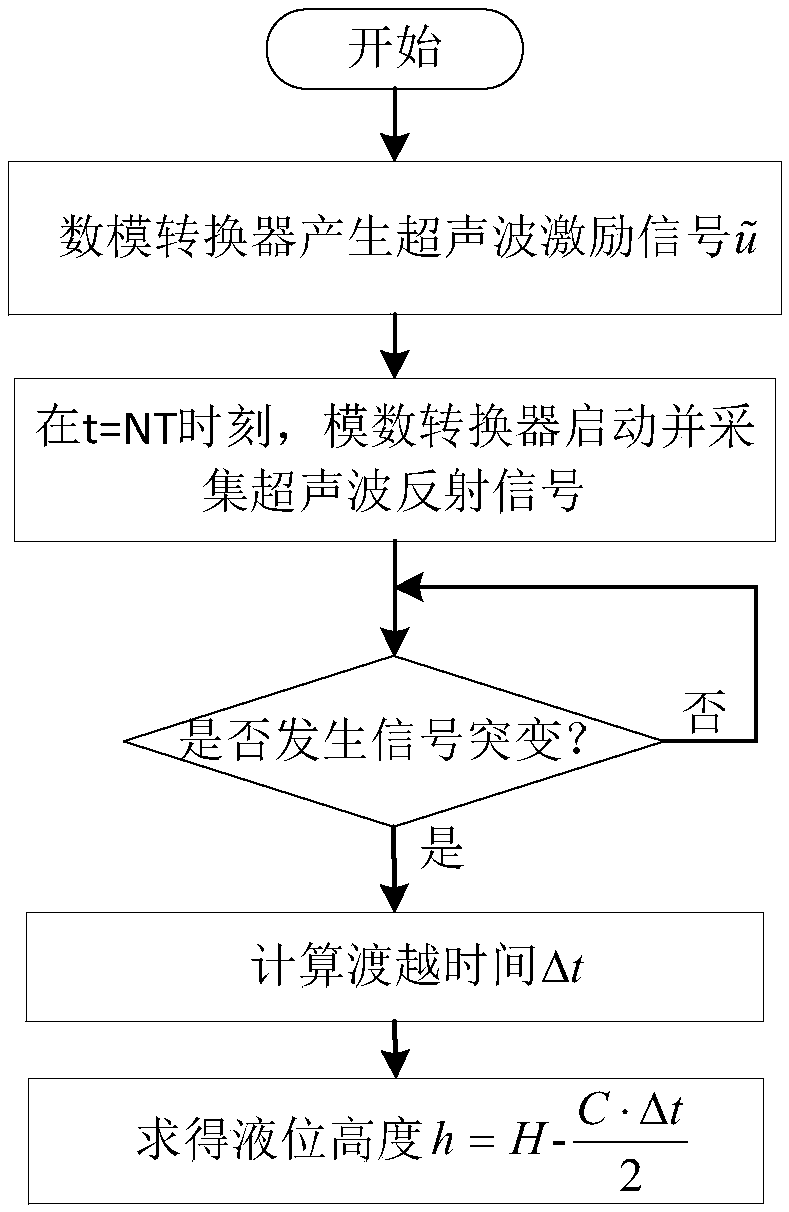

[0047] This embodiment relates to an oil cup liquid level measuring device of a range hood and a measuring method thereof. The oil cup liquid level measuring device of this embodiment adopts the principle of ultrasonic distance measurement, specifically, adopts the time of flight method TOF (time of flight ): First measure the time elapsed from the time the ultrasonic wave is emitted to when it encounters an obstacle, and then multiplied by the speed of the ultrasonic wave to obtain twice the distance between the sound source and the obstacle.

[0048] Such as figure 1 , figure 2 As shown, it is a schematic diagram of the oil cup liquid level measuring device of this embodiment. The oil cup liquid level measuring device is arranged in the range hood main body directly above the oil cup. The oil cup liquid level device specifically includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com