Eccentricity adjustable sliding bearing test device

A technology for sliding bearings and testing devices, which is applied in the direction of mechanical bearing testing, measuring devices, and force sensors related to bearings. Simple, convenient installation and disassembly, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

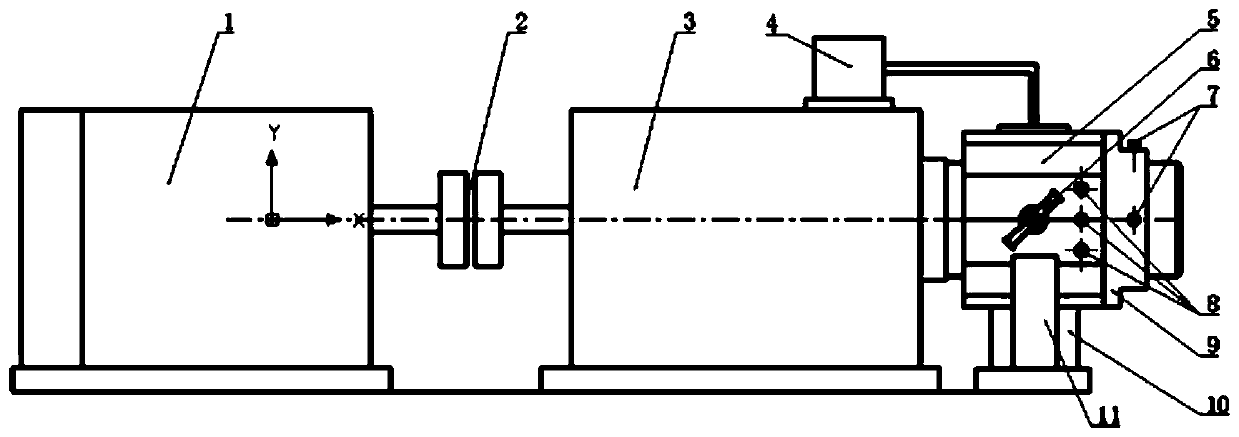

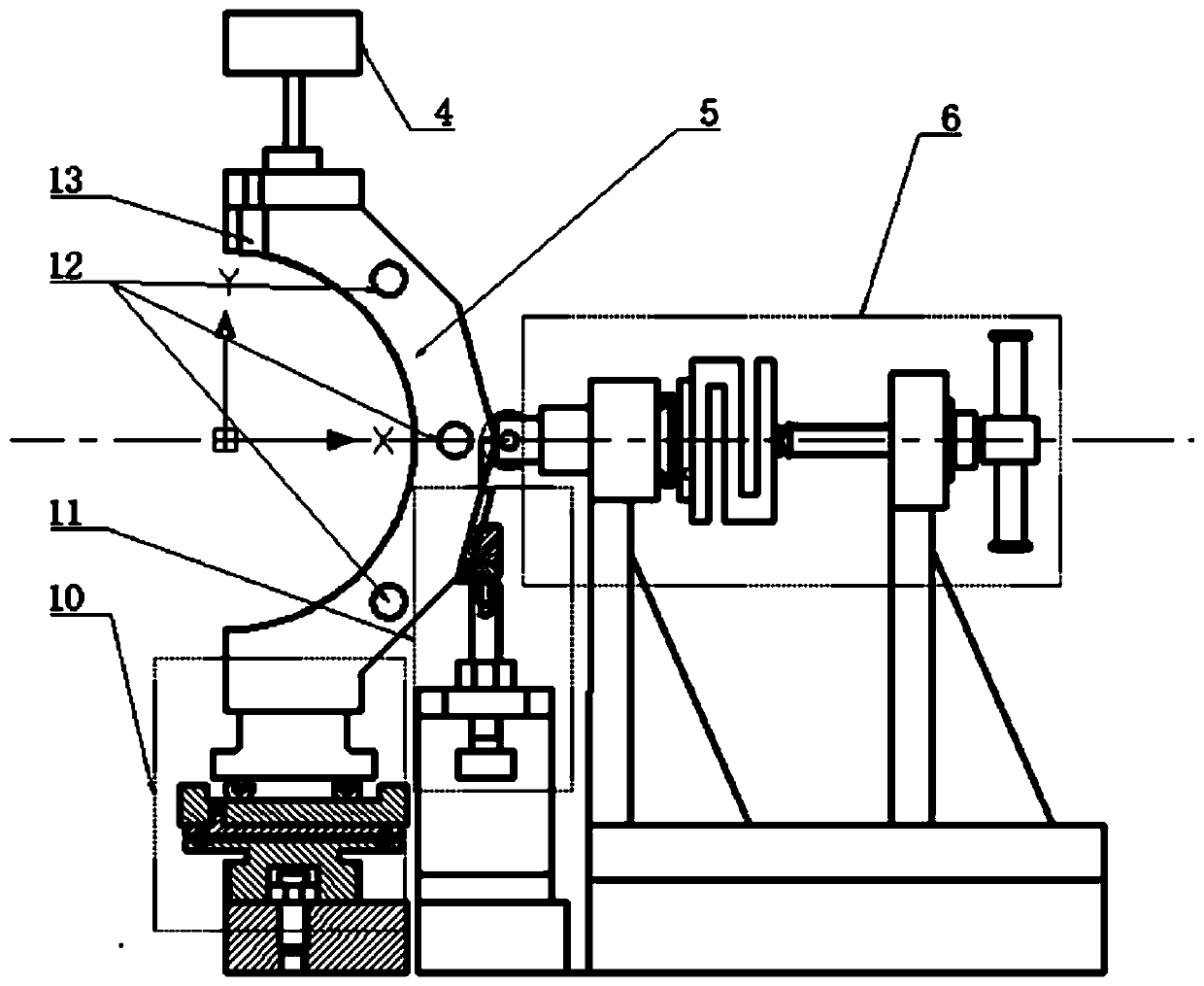

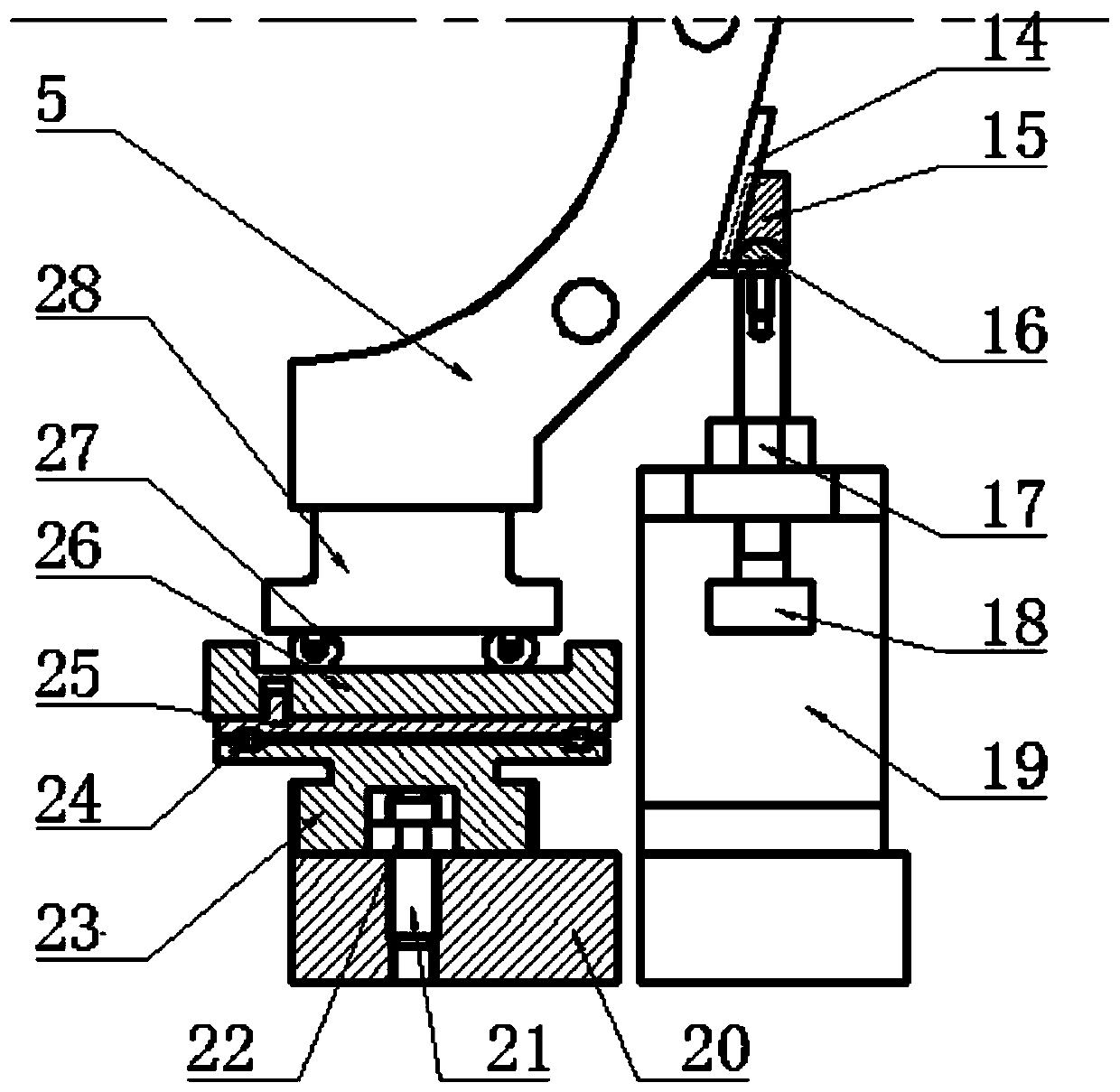

[0022] This embodiment is a sliding bearing test device with adjustable eccentricity.

[0023] refer to Figure 1 to Figure 6 , the sliding bearing test device with adjustable eccentricity in this embodiment consists of a drive motor 1, a shaft coupling 2, a headstock 3, a torque sensor 4, a test bearing bush 5, a loading device 6, a displacement sensor 7, a pressure sensor 8, and an end cover method Lan 9, vertical direction adjustment structure 10, horizontal direction adjustment structure 11, temperature sensor 12, oil inlet 13, side guide rail 14, wedge-shaped slider 15, hemispherical connector 16, lock nut 17, fine thread bolt 18, Horizontal direction adjustment structure support 19, base 20, bolt 21, nut 22, rotating sleeve 23, ball 24, disc 25, horizontal guide rail 26, roller 27, horizontal support 28; wherein, the driving motor and the spindle box 3 One end of the main shaft is connected through the coupling 2, and the other end of the main shaft of the main shaft bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com